Aspheric part trace forming processing method and its equipment

A processing method and forming processing technology, applied in feeding devices, metal processing, automatic control devices, etc., can solve problems such as complex operation technology, inapplicability to batch production, and long processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

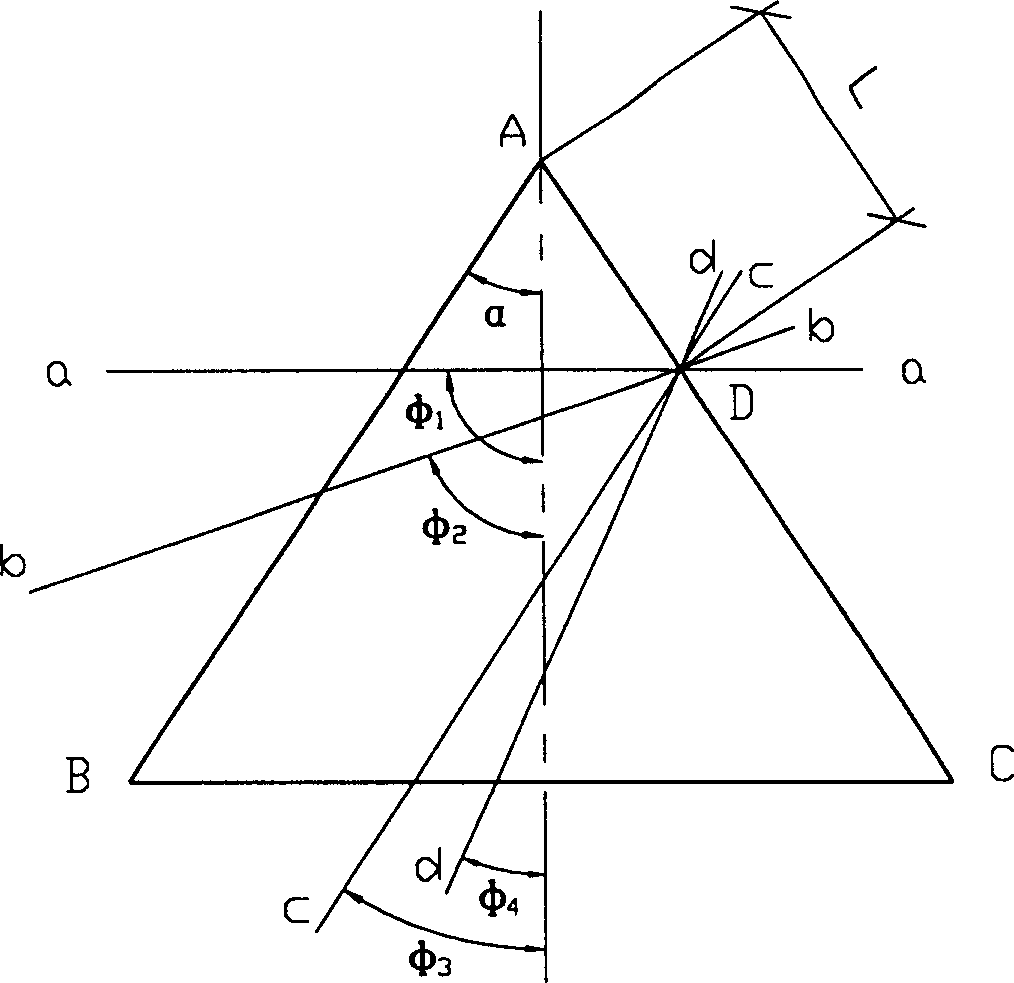

[0018] Such as figure 1 Shown is a schematic diagram of the trajectory intercepted in a cone. On a cone with a half-vertex angle α, from the vertex A to a certain point D along the generatrix of the cone whose distance is L, if a plane a-a is used to truncate the cone, the angle between the plane and the axis of the cone is φ 1 =90°, the trajectory of the curve equation of a circle can be cut; if the angle between the plane b-b and the axis of the cone is 90°>φ 2 > within the range of α, the trajectory of an ellipse curve equation can be cut; if the angle between the plane c-c and the axis of the cone is φ 3 = α, the trajectory of a parabolic curve equation can be cut; if the angle between the plane d-d and the axis of the cone is α>φ 4 >-α range, can cut a hyperbolic curve equation track. In a word, any given quadratic curve equation trajectory can be intercepted on the cone only by obtaining the parameters α, φ and L related to the given quadratic curve equation. How to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com