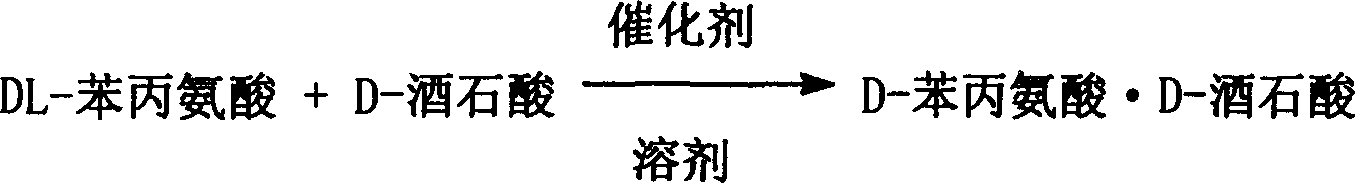

Method for preparing dextrorotary phenylalanine by asymmetric conversion method

A technology of dextro-phenylalanine and phenylalanine is applied in the field of preparation of chiral organic compounds to achieve the effects of improving adaptability, reducing usage, and avoiding entrainment and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0014] Example 1 Dissolve the mixture of 6.6g DL-phenylalanine and 6.0g D-tartaric acid in 100.0mL propionic acid, add 1-5% aromatic aldehyde, stir at 70-90°C for 6-8 hours, cool to After cooling at room temperature for 0.5 hours in an ice-water bath, filter and the mother liquor can be recycled. The solid was washed with anhydrous ether and dried to obtain 11.0 g of white crystals of D-tartrate·D-phenylalanine salt, with a yield of 87.7%.

example 2

[0015] Example 2 Dissolve the mixture of 9.9g DL-phenylalanine and 9.0g D-tartaric acid in 120.0mL propionic acid, and others are the same as example 1 to obtain 15.60g of white crystals of D-tartaric acid D-phenylalanine salt, Yield 82.5%. Then D-phenylalanine can be prepared from D-tartaric acid·D-phenylalanine salt.

[0016] Example 3 Dissolve the D-tartrate·D-phenylalanine salt obtained in Example 1 in 9.86ml of triethylamine and 67ml of absolute ethanol, stir at room temperature for 1 hour, then cool to 5-10°C, filter and wash the solid with an appropriate amount of ethanol 1 to 3 times to obtain 4.66 g of D-phenylalanine as a white solid with a yield of 80.5%. [α] D 20 =+33.7°.

example 4

[0017] Example 4. Dissolve 11.05 g of D-tartaric acid D-phenylalanine salt in 9.86 ml of triethylamine and 67 ml of methanol, stir at room temperature for 1 hour, then cool to 5-10°C, filter and wash the solid with an appropriate amount of methanol for 1- Three times, 4.24 g of white solid D-phenylalanine was obtained, and the yield was 73.2%.

[0018] Example 5 Dissolve 11.05 g of D-tartrate·D-phenylalanine salt in 5 times the amount of water, add 2 times the amount of concentrated ammonia water, stir at room temperature for 1 hour, cool to 5-10°C, filter and wash with appropriate amount of cold water Solid 1 to 3 times. The solid obtained after concentrating the mother liquor was combined with the aforementioned solid to obtain 4.14 g of D-phenylalanine crystals, with a yield of 71.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com