Method for setting super crystalline lattice all solid state red-yellow-green-blue four-color laser

A superlattice, all-solid-state technology used in lasers, laser components, structure/shape of optical resonators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

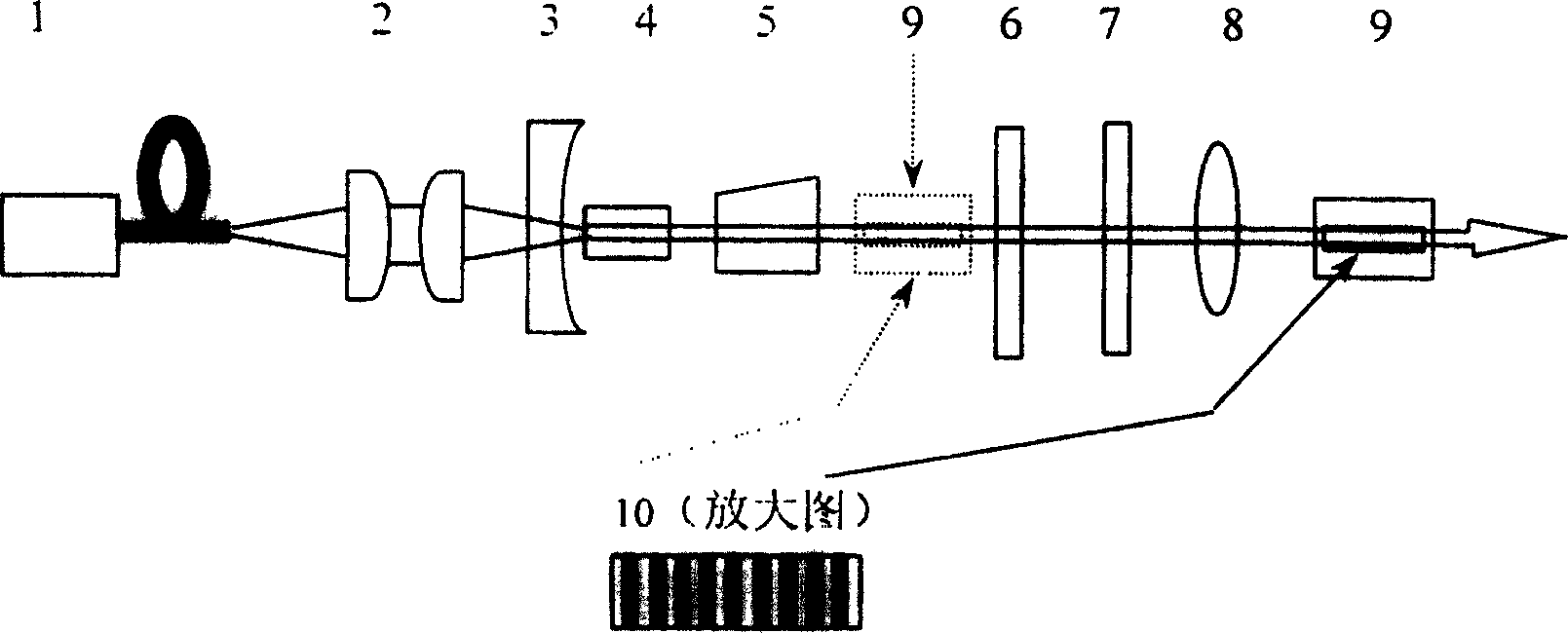

[0062] Implementation example 1 is attached according to the instructions figure 1 Make a superlattice all-solid-state red, yellow, green and blue four-color laser (already realized). The output wavelength of the pump source LD is 0.808μm, and the maximum output power is 30W. Nd:YVO 4 The front and rear surfaces of the crystal 4 are coated with 1.064 and 1.342 μm anti-reflection coatings. The input mirror 3 is highly reflective to both 1.064 μm and 1.342 μm, and forms a 1.342 μm laser resonant cavity with cavity mirror 6, and a 1.064 μm laser resonant cavity with cavity mirror 7. The acousto-optic switch 5 is placed in the cavity to obtain quasi-continuous 1.064 μm and 1.342 μm laser light. A non-periodically polarized LT superlattice 10 (about 1 cm in length) is placed in a temperature-controlled furnace 9 to adjust the temperature. Simultaneous output of red, yellow, green and blue four-color lasers can be obtained at the matching temperature.

Embodiment 2

[0064] According to the manual attached figure 1 Make a superlattice all-solid-state red, yellow, green and blue four-color laser. The difference from Example 1 is that both ends of the superlattice 10 are coated with 1.064 μm and 1.342 μm antireflection coatings and visible light antireflection coatings. The input mirror 3 is also highly reflective to visible light, the output cavity mirror 6 is 1.342 μm high and 1.064 μm and visible light is highly transparent, and the output cavity mirror 7 is 1.064 μm high and visible light is highly transparent. frequency conversion. Simultaneous output of red, yellow, green and blue four-color lasers can be obtained at the matching temperature.

Embodiment 3

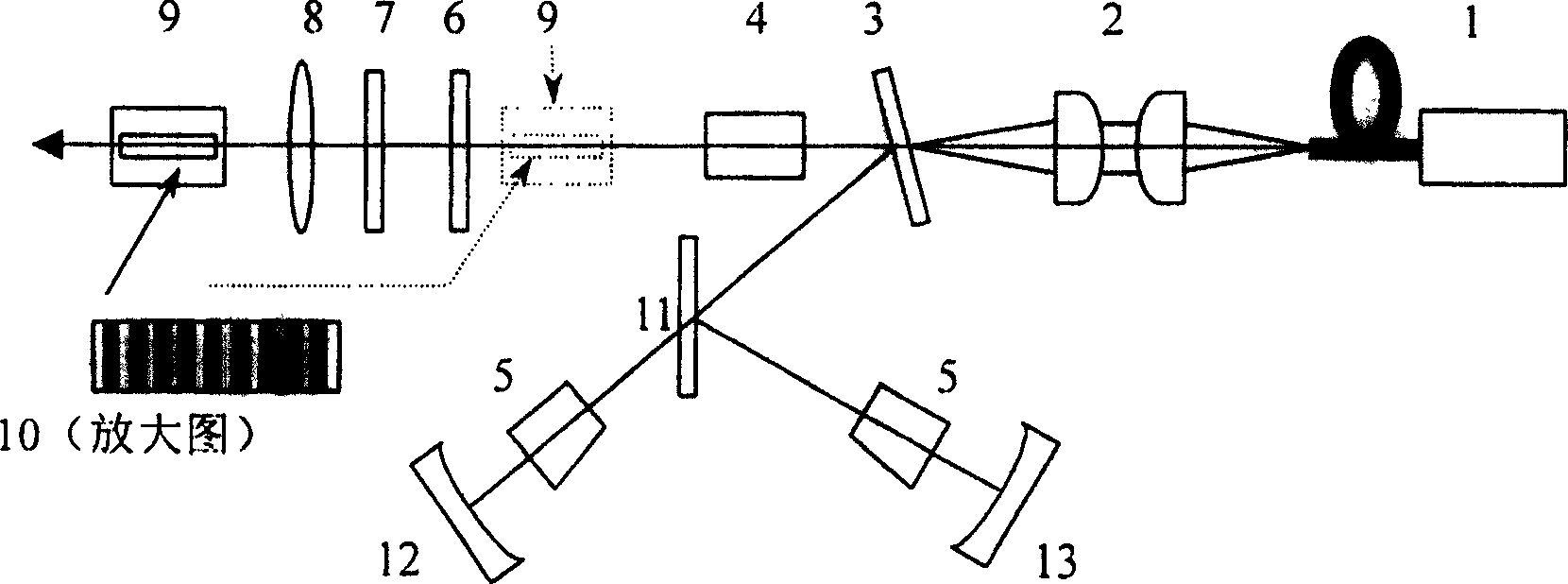

[0066] According to the manual attached figure 2 Make a superlattice all-solid-state red, yellow, green and blue four-color laser. The difference from examples 1 and 2 is that the method of folding and shunting is adopted. The input mirror 3 is highly reflective to both 1.064μm and 1.342μm, 11 is a 45° beam splitter, which is highly reflective to 1.342μm and highly transparent to 1.064μm; 12 and 13 are cavity mirrors with high reflection to 1.064μm and 1.342μm respectively. The 1.342μm laser oscillates between 13 and 6, and the 1.064μm laser oscillates between 12 and 7. The quasi-continuous light generated by the acousto-optic modulator can adjust the time delay of the two acousto-optic control signals to suppress dual-wave competition or improve the synchronization characteristics (time overlap) of dual-wave pulses. Outside the chamber, the superlattice 10 is placed in a temperature-controlled furnace 9 to adjust the temperature. Simultaneous output of red, yellow, green ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com