Treating method of industrial and domestic sludge

A domestic sludge and industrial technology, applied in the field of sludge treatment, can solve the problems of crops and flowers hazards, sludge heavy metal enrichment, large land occupation, etc., achieve good social and economic benefits, simple structure, and save operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

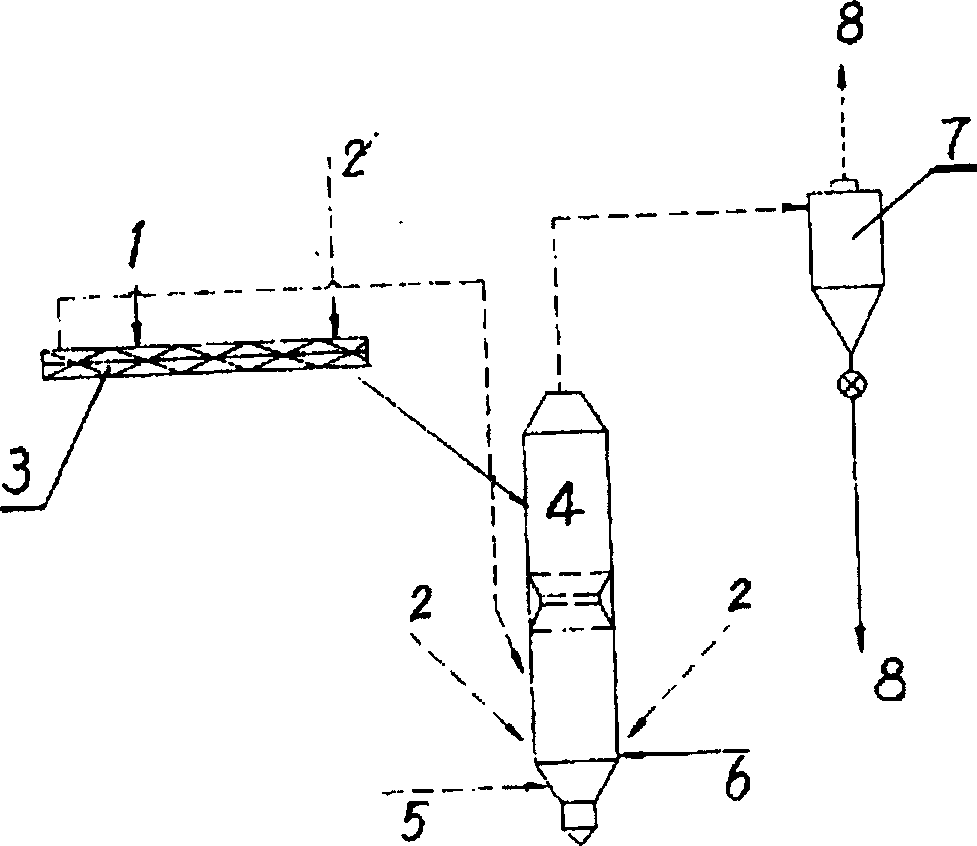

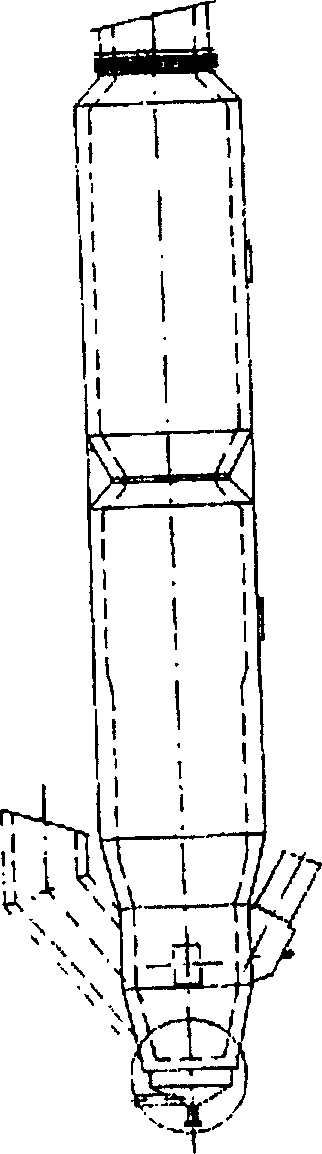

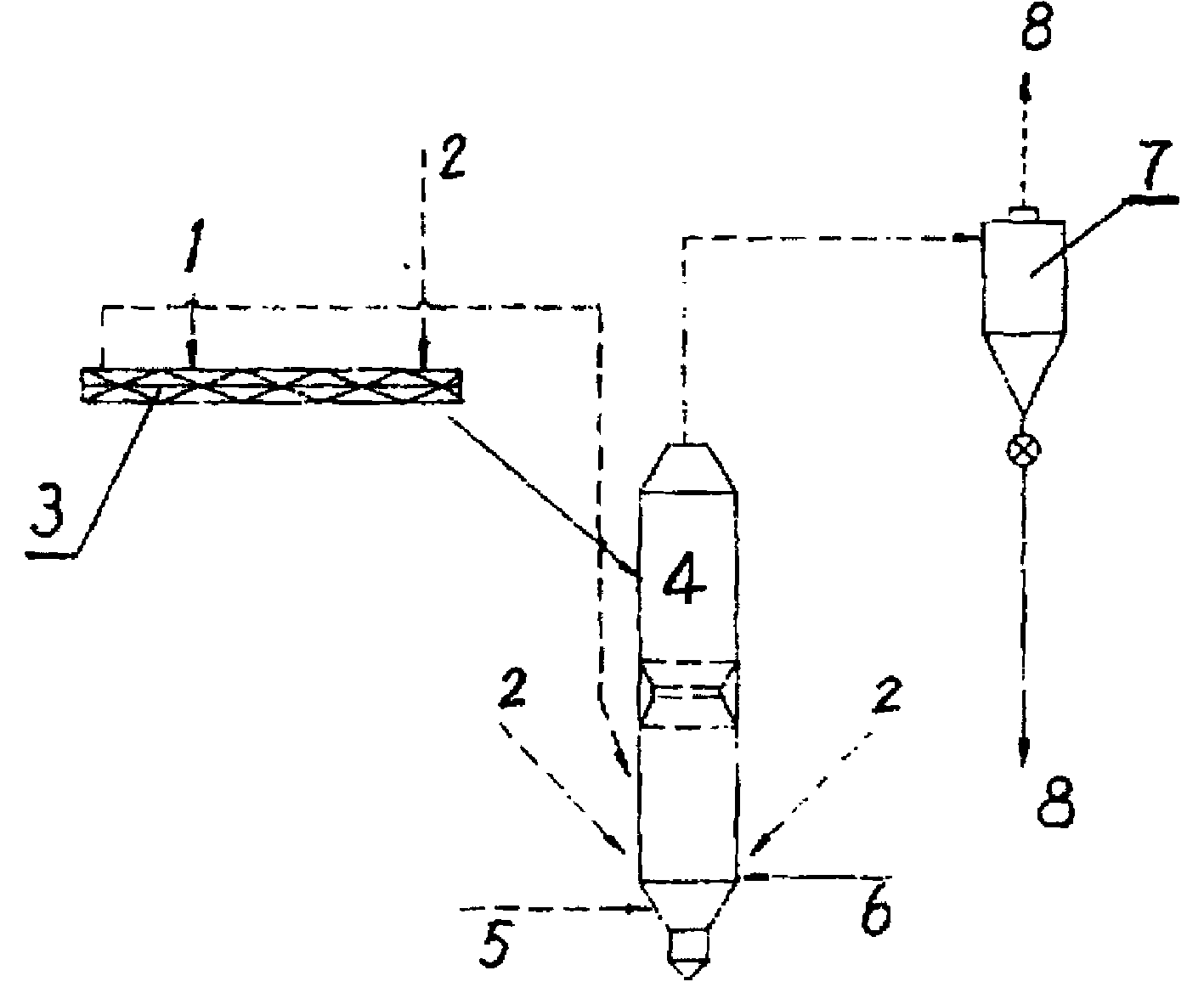

[0011] Such as figure 1 As shown, the present invention includes a drying mixer 3, a fluidized suspension furnace 4 and a high-efficiency cyclone dust collector 7, which are placed near the cement clinker burning system to dry and incinerate the sludge 1. The specific process is introduced as follows: the fresh sludge 1 with a water content of 75% directly enters the drying mixer 3, and the drying heat source of the mixer 3 comes from the tertiary air 2 heated by the kiln head of the cement clinker firing. After adding cold air, it enters the drying The temperature of the gas in the mixer 3 is 250°C. The sludge 1 exiting the drying mixer 3 is sent to the suspension furnace 4 with a fluidized bed, and the waste gas exiting the mixer 3 enters the suspension furnace 4 for further combustion. Coal powder 6 is supplemented in the furnace of the suspension furnace 4 so that the dried sludge 1 can be completely incinerated therein, and another part of the tertiary air 2 from the kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com