Harmless treatment method for electrolytic manganese residues

A technology of electrolytic manganese slag and disposal method, applied in the direction of removal of solid waste, etc., can solve the problems of high cost and poor effect, and achieve the effects of low cost, cost reduction and speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

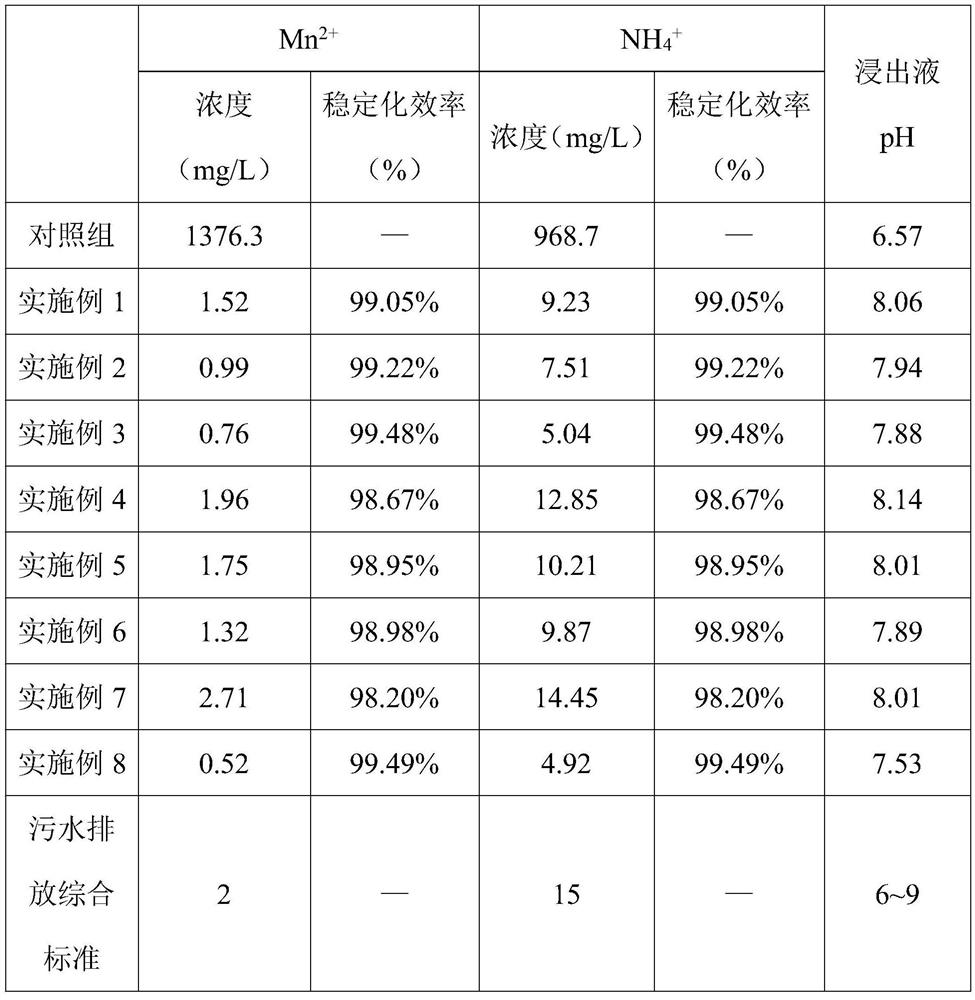

Examples

Embodiment 1

[0027] A harmless disposal method for electrolytic manganese slag, comprising the following steps:

[0028] (1) electrolytic manganese slag is placed in a crusher to be crushed to particle size<0.84mm;

[0029] (2) take by weighing the electrolytic manganese slag after 30g crushing;

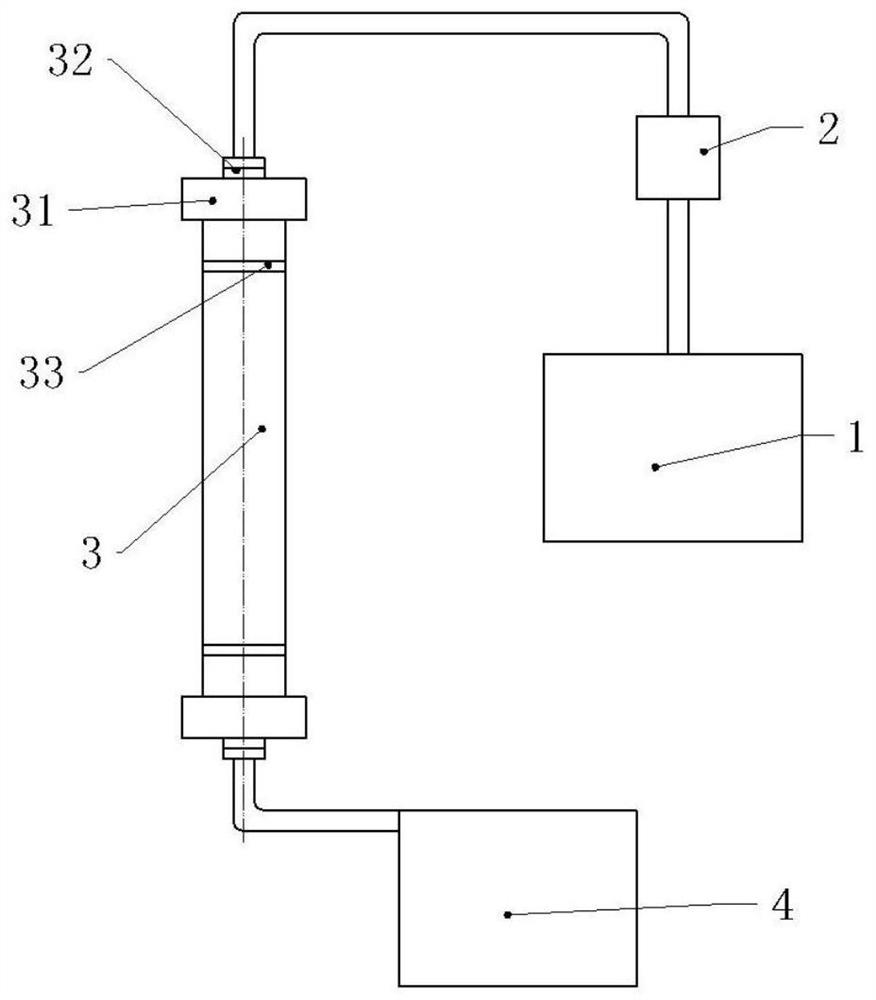

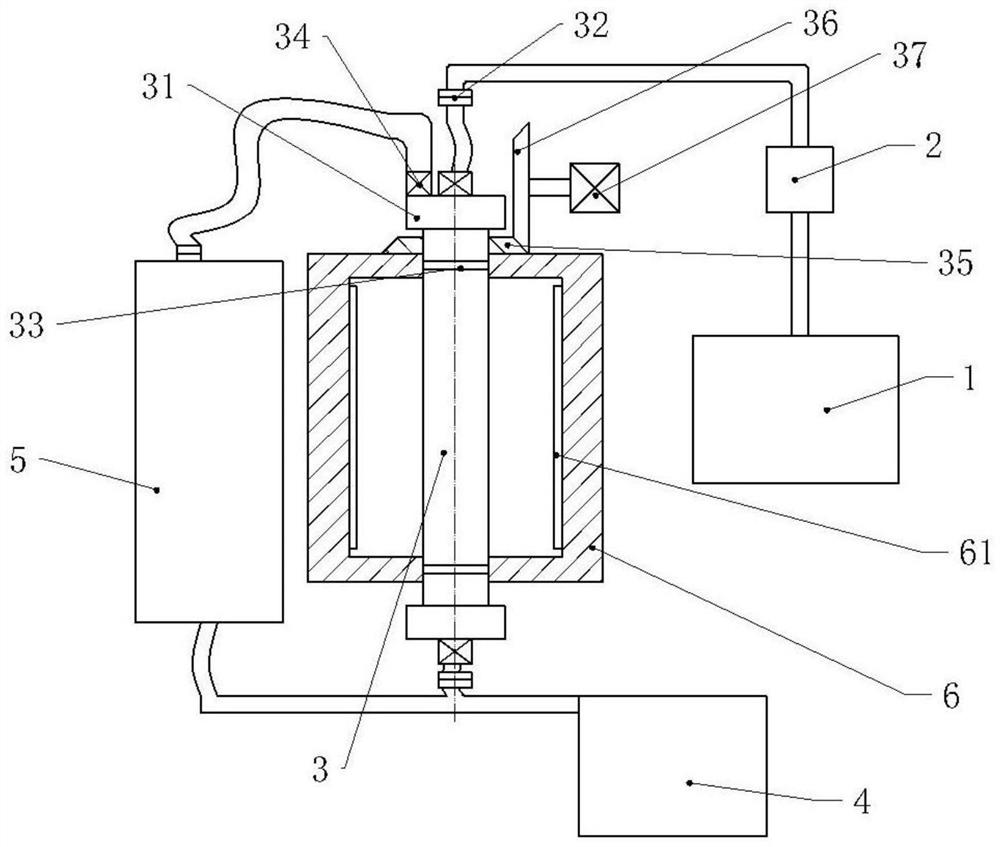

[0030] (3) prepare a leaching agent and build a leaching device to complete the leaching operation, and the leaching agent in the present embodiment is a 5g / L citric acid solution; as figure 1 As shown, the leaching device includes a rack, an leaching liquid tank 1, a peristaltic pump 2, a leaching column 3 and a leaching liquid tank 4, and the leaching liquid tank 1, the peristaltic pump 2, the leaching column 3 and the leaching liquid tank 4 are all installed in the On the rack, the axis of the rinsing column 3 is arranged along the vertical direction, the rinsing column 3 is annular and the upper and lower ends are open, and the inner sides of the upper and lower ends of the rinsing column 3 ...

Embodiment 2

[0032] The difference between Example 2 and Example 1 is: the particle size of the electrolytic manganese slag after crushing is less than 0.84 mm, the leaching agent is 7.5g / L citric acid solution, the flow rate of the leaching agent is controlled to be 1 mL / min, and the leaching time is 360min.

Embodiment 3

[0034] The difference between Example 3 and Example 1 is: the particle size of the broken electrolytic manganese slag is less than 0.84mm, the leaching agent is 10g / L citric acid solution, the flow rate of the leaching agent is controlled to be 1mL / min, and the leaching time is 360min .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com