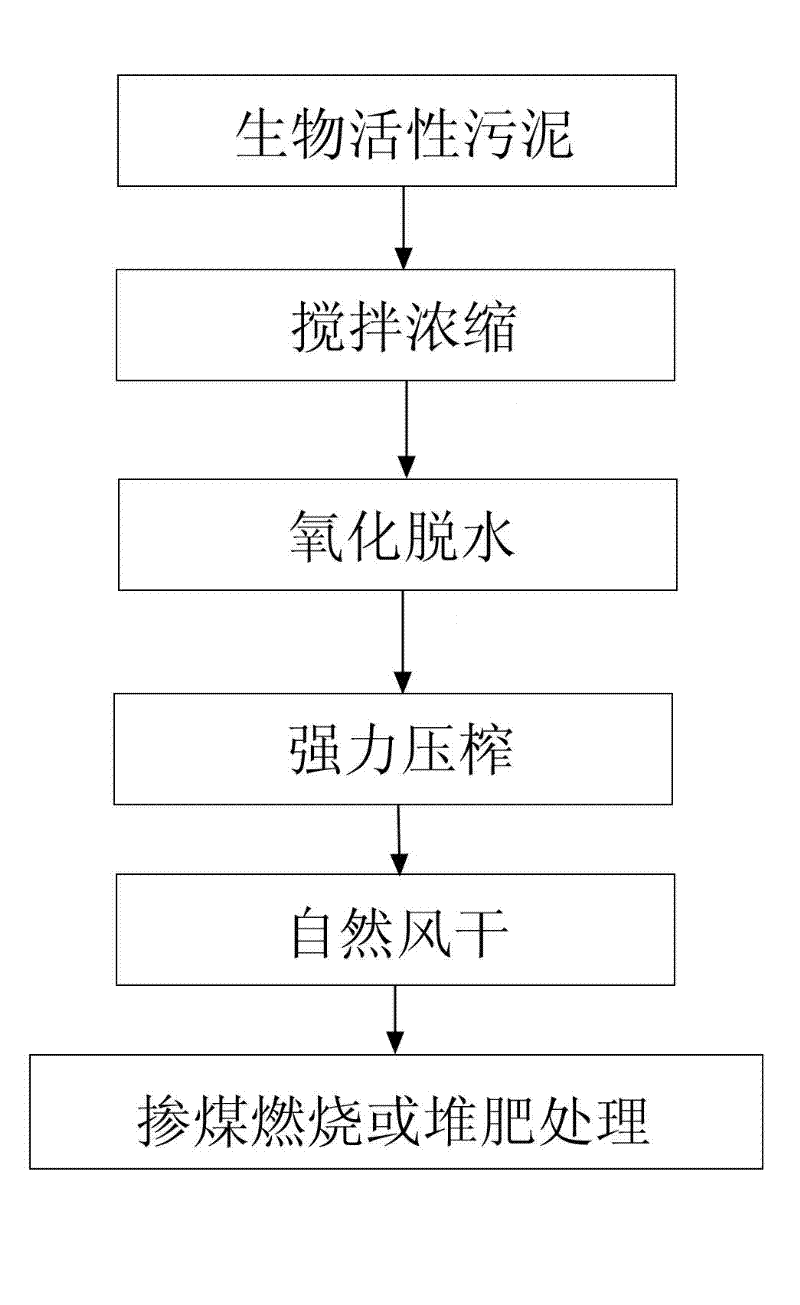

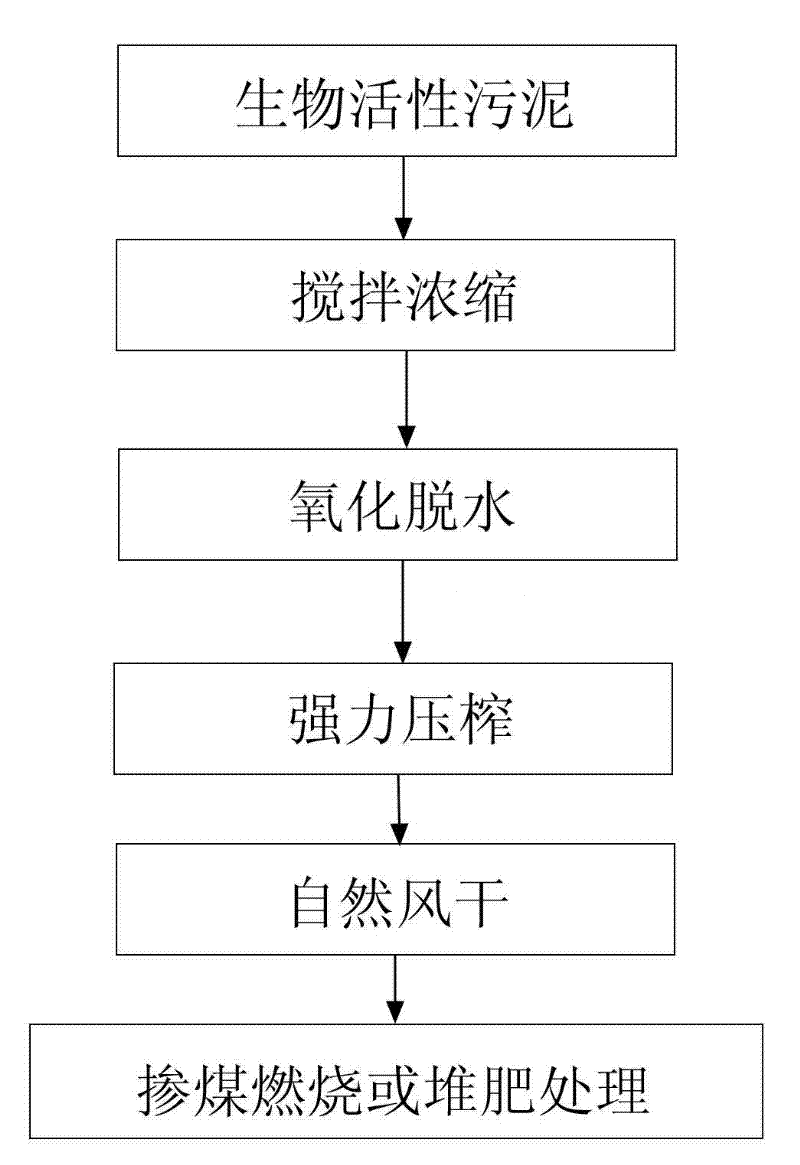

Reducing and recycling treatment method for biological activated sludge

A biological activity, sludge reduction technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve secondary pollution, cannot meet environmental protection requirements, and is easily corrupted Odor and other problems, to achieve the effect of great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this example, in the sewage treatment station of COFCO Malt (Dalian) Co., Ltd., the activated sludge produced by the biochemically treated sewage enters the sludge storage tank. The sludge is characterized by a moisture content of 3 ; Chlorine dioxide is used to strengthen the sludge concentration and dehydration treatment, and the addition amount is 3kg / m 3 (calculated as available chlorine), the water content of the sludge is reduced from 98% to 95%, and the volume of the sludge is reduced from 500m 3 down to 200m 3 Add dewatering agent to sludge, dewatering agent is polyaluminum chloride and quicklime mix according to mass ratio as 1: 1 ratio, and addition is 8 kg / m 3 ; After the mixed sludge is pumped into the diaphragm plate and frame filter press through the screw pump, the pressure is kept at 0.6mpa for 1 hour, and then the diaphragm pressing system is started, and the pressure of 1.6mpa is pressed for 1 hour. The moisture content of the sludge after strong p...

Embodiment 2

[0030] The activated sludge produced by the biochemically treated sewage enters the sludge storage tank. The sludge is characterized by a water content of 3 ; Use sodium hypochlorite to strengthen the sludge concentration and dehydration treatment, the addition amount is 5kg / m 3 (calculated as available chlorine), the water content of the sludge is reduced from 98% to 95%, and the volume of the sludge is reduced from 500m 3 down to 200m 3 ;Add dehydrating agent polyacrylamide to the sludge, the addition amount is 0.5kg / m 3 ; After the mixed sludge is pumped into the diaphragm plate and frame filter press through the screw pump, it is first kept at a pressure of 0.6mpa for 1 hour, and then the diaphragm pressing system is started to press for 1 hour at a pressure of 1.8mpa. The moisture content of the sludge after strong pressing is reduced to 60%, and the sludge volume is 25m 3 ;Pile up the squeezed massive sludge naturally, and after air-drying for a week, the moisture cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com