System and method for treating printing and dyeing sludge by using waste heat of setting waste gas from printing and dyeing mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

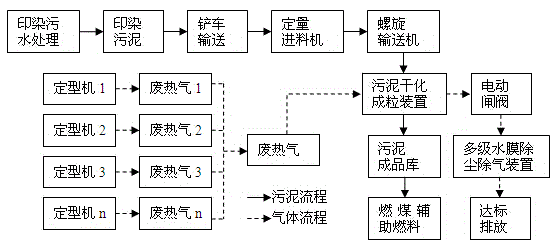

[0027] The printing and dyeing sludge with a moisture content of 78% is sent to the sludge drying and granulating device through a quantitative feeder and a screw conveyor; the hot exhaust gas discharged from two printing and dyeing factory setting machines is passed through each exhaust pipe and concentrated to a main exhaust pipe, and the concentrated hot waste gas is sent to the sludge drying and granulating device; in the sludge drying and granulating device, the wet sludge is in direct contact with the hot waste gas, and through the heat exchange process, the wet sewage When the water is evaporated and dried, the mud naturally forms particles with a particle size of 1-10 mm, and wraps the fibers and oil mist in the adsorbed shaped waste gas into the particles; the shaped hot waste gas passes through the drying process of printing and dyeing sludge. The temperature of the exhaust gas has dropped to 90°C, and the concentration of fibers and oil mist has been greatly reduced....

Embodiment 2

[0029]The printing and dyeing sludge with a moisture content of 85% is sent to the sludge drying and granulating device through a quantitative feeder and a screw conveyor; the hot waste gas discharged from 6 sets of printing and dyeing factory setting machines is passed through each exhaust pipe and concentrated to a main exhaust pipe, and the concentrated hot waste gas is sent to the sludge drying and granulating device; in the sludge drying and granulating device, the wet sludge is in direct contact with the hot waste gas, and through the heat exchange process, the wet sewage When the water is evaporated and dried, the mud naturally forms particles with a particle size of 1-10 mm, and wraps the fibers and oil mist in the adsorbed shaped waste gas into the particles; the shaped hot waste gas passes through the drying process of printing and dyeing sludge. The temperature of the exhaust gas has dropped to 110°C, and the concentration of fibers and oil mist has been greatly redu...

Embodiment 3

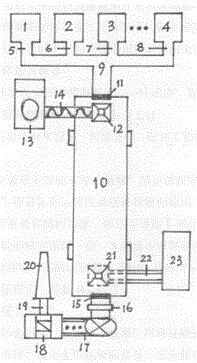

[0031] The printing and dyeing sludge with a moisture content of 80% is sent to the quantitative feeder through a forklift, and the printing and dyeing sludge coming out of the quantitative feeder passes through a screw conveyor and enters a sludge dryer with a diameter of 2.0m and a length of 25m. In the granulation device, the temperature is 160°C and the total gas volume reaches 60,000m through a main pipe connecting the exhaust pipes of 3 setting machines. 3 The hot exhaust gas per hour is sent to the sludge drying and granulating device, and directly contacts with the printing and dyeing sludge. With the continuous rotation of the sludge drying and granulating device, the wet sludge and hot exhaust gas are separated in sufficient space and time. After the heat exchange process is completed, the moisture content of the sludge will drop to 40-45%, and the volume will be reduced to less than one-third. At the same time, particles with a particle size of 1-10mm will be natural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com