Durable anti-static agent for acrylic fiber

A technology of antistatic agent and durability, which is applied in the field of durable antistatic agent for acrylic fiber and its preparation, which can solve the problems of uneven curing and low curing rate, and achieve fast curing reaction speed, excellent antistatic performance and stable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

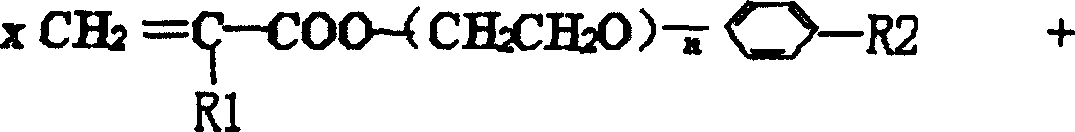

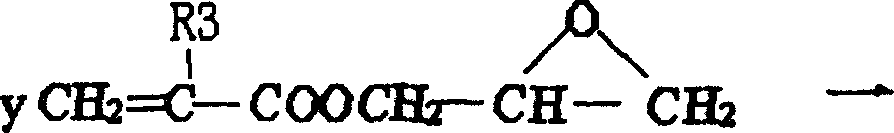

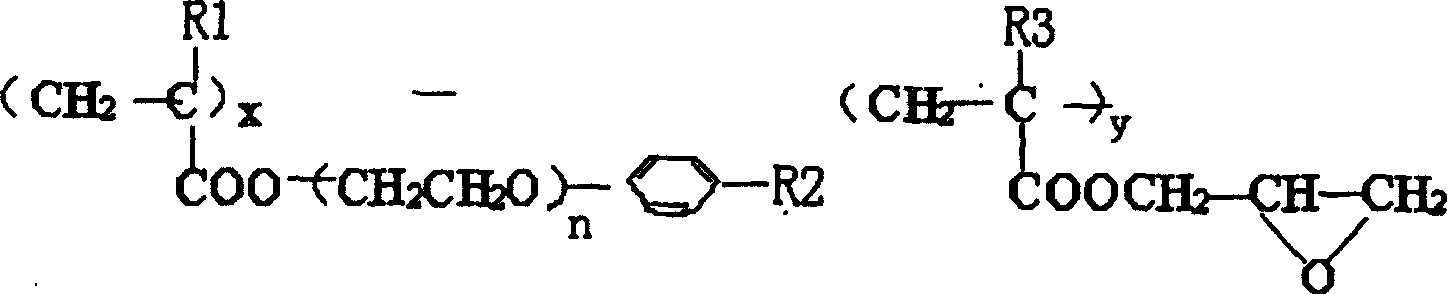

Method used

Image

Examples

Embodiment 1

[0037] In a 500ml reactor equipped with a reflux condenser and a stirring device, add 90g of dimethylformamide, 20g of alkylphenol polyoxyethylene ether (meth)acrylate (the repeating number of ethylene oxide units is 15), 1.0 g glycidyl methacrylate, start stirring, feed nitrogen, and heat up to 75°C.

[0038] Weigh 0.5g of azobisisobutylcyanide and dissolve it in 10g of dimethylformamide, and weigh another 2.0g of glycidyl methacrylate. After the reaction temperature reaches 75°C, add the initiator solution into the reactor five times. The interval is 1.5 hours; 2.0 g of glycidyl methacrylate is added into the reactor three times with an interval of 1.5 hours. After constant temperature reaction for 10 h, the monomer conversion rate was 90.5% according to sampling analysis.

[0039] Weigh 2.0g of the above reaction solution, add 100g of distilled water, stir and mix evenly, then add 0.2g of 2,4,6--tris(N,N-dimethyl)-amino-phenol, stir evenly, this is antistatic agent soluti...

Embodiment 2

[0042] In a 500ml reactor equipped with a reflux condenser and a stirring device, add 90g dimethyl sulfoxide, 30g alkylphenol polyoxyethylene ether (meth)acrylate (the repeating number of ethylene oxide units is 30), 0.6g Glycidyl methacrylate, start stirring, feed nitrogen, and raise the temperature to 85°C.

[0043] Weigh 0.5g of azobisisoheptyl cyanide and dissolve it in 10g of dimethyl sulfoxide, and weigh 1.5g of glycidyl methacrylate in addition. After the reaction temperature reaches 75°C, add the initiator solution into the reactor five times, interval 1.5 hours; 1.5 g of glycidyl methacrylate was added to the reactor three times with an interval of 1.5 hours. After constant temperature reaction for 15 hours, the monomer conversion rate was 91.2% according to sampling analysis.

[0044] Weigh 2.0g of the above reaction solution, add 100g of distilled water, stir and mix evenly, then add 0.1g of 2,4,6-tri(N,N-dimethyl)-amino-phenol, stir evenly, this is the antistatic ...

Embodiment 3

[0047] In a 500ml reactor equipped with a reflux condenser and a stirring device, add 90g of dimethylformamide, 40g of alkylphenol polyoxyethylene ether (meth)acrylate (the repeating number of oxyethylene units is 50), 1.0 g glycidyl methacrylate, start stirring, feed nitrogen, and heat up to 75°C.

[0048] Weigh 0.5g of azobisisobutylcyanide and dissolve it in 10g of dimethylformamide, and weigh another 2.0g of glycidyl methacrylate. After the reaction temperature reaches 75°C, add the initiator solution into the reactor five times. The interval is 1.5 hours; 2.0 g of glycidyl methacrylate is added into the reactor three times with an interval of 1.5 hours. After constant temperature reaction for 10 h, the monomer conversion rate was 90.5% according to sampling analysis.

[0049] Weigh 2.0g of the above reaction solution, add 100g of distilled water, stir and mix evenly, then add 0.2g of 2,4,6--tris(N,N-dimethyl)-amino-phenol, stir evenly, this is antistatic agent solution....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com