Novel large-torque pizoelectric motor

A piezoelectric motor and high torque technology, applied in the field of motors, can solve the problems of no price competitive advantage, difficult to guarantee stability, and high tolerance requirements of drive shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

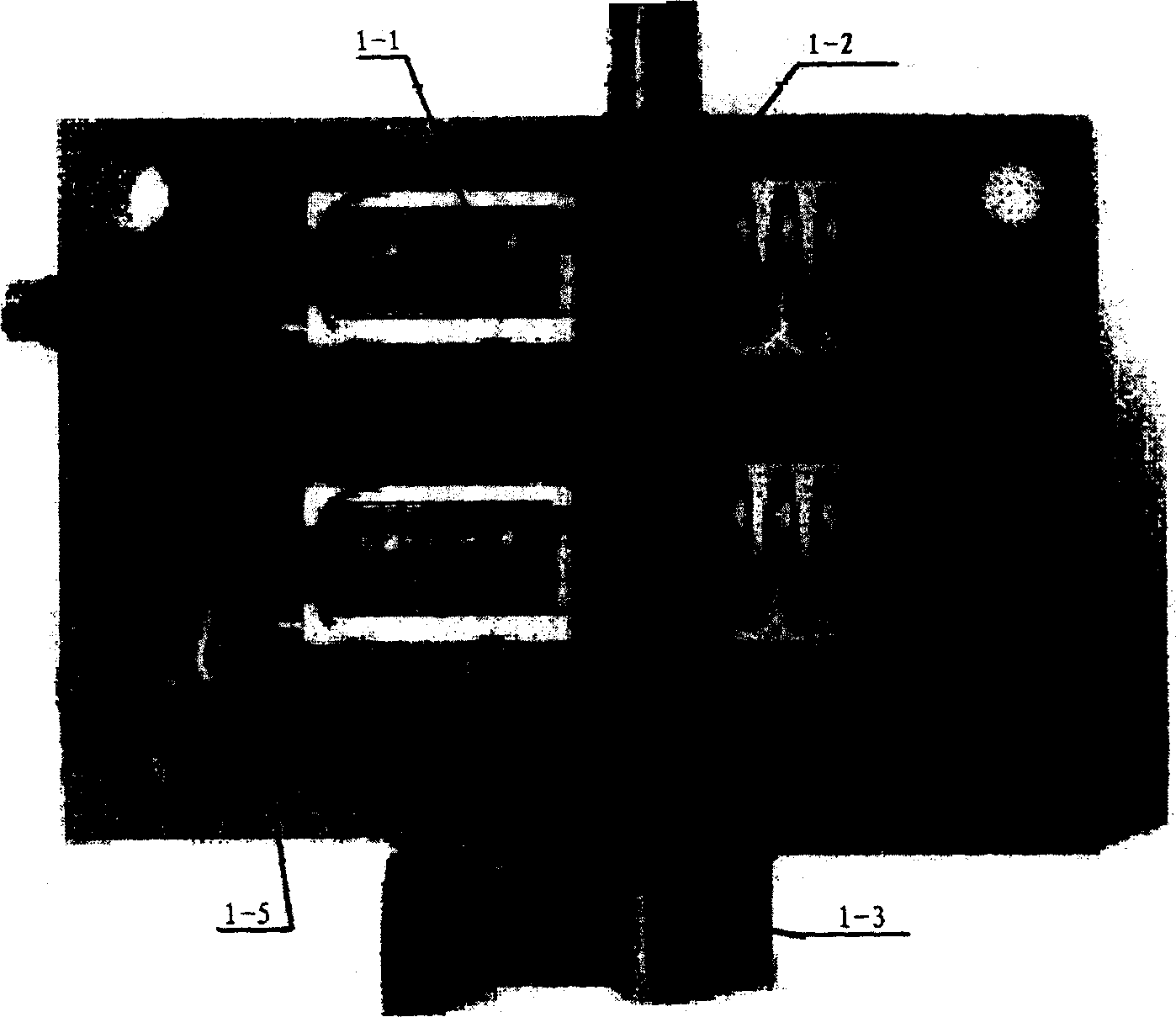

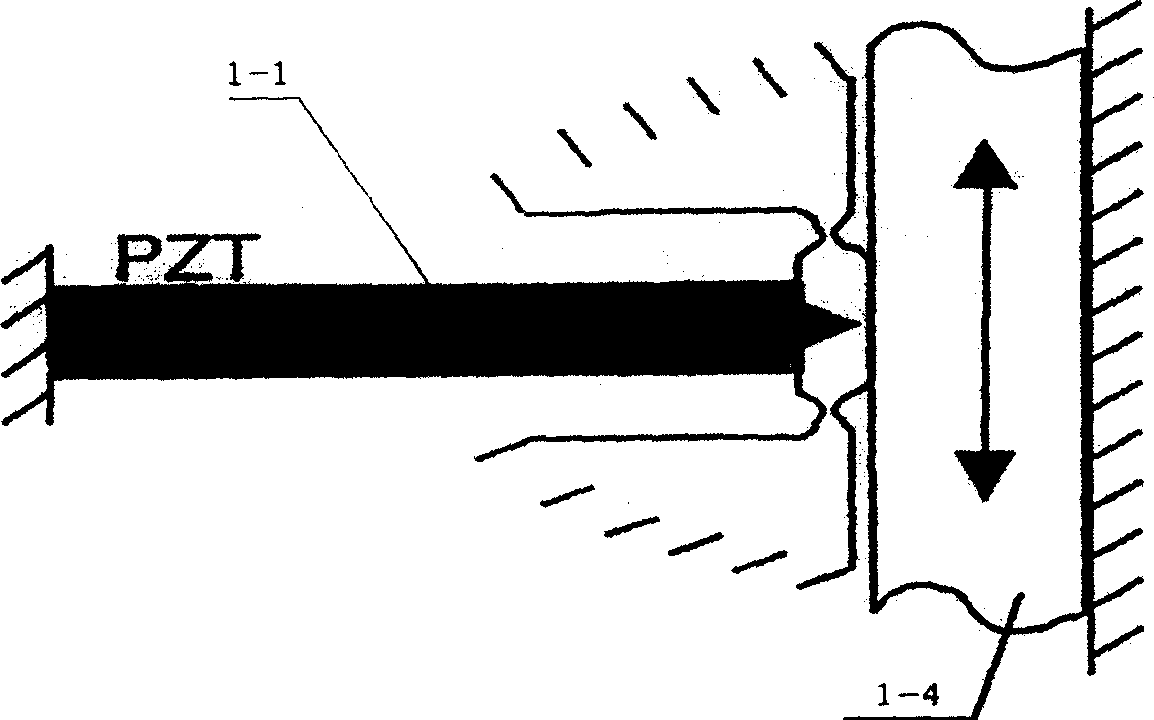

[0033] Such as Figure 3-8 As shown, the high-torque piezoelectric motor includes a piezoelectric driving piece 1, a mass block 2, a hub 3, a ball holder 4 and a drive shaft 5, wherein the piezoelectric driving piece 1 is composed of two facing piezoelectric ceramic pieces 11 Composed of elastic metal sheets 12, ceramic sheets 11 are respectively pasted on both sides of the metal sheet 12, after the ceramic sheet 11 is polarized along the "3" direction, when an external electric field is applied, the upper and lower surfaces of the piezoelectric driving sheet 1 elastically expand or Shrink, so that the driving piece 1 bends. In order to make it generate greater swing and torsion, each double-layer piezoelectric driving piece 1 is suspended on the center blade hub 3 including the ball holder 4, and its end away from the center blade hub 3 hangs a ceramic or heavy metal. Mass block 2, to increase the inertia and torque when rotating. When a signal voltage with a frequency equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com