Method for driving power semiconductor element

A technology of power semiconductors and components, applied in the direction of semiconductor devices, output power conversion devices, electrical components, etc., can solve the unaccepted and complicated problems of double-door GTO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In all figures, the same reference signs correspond to the same working parts.

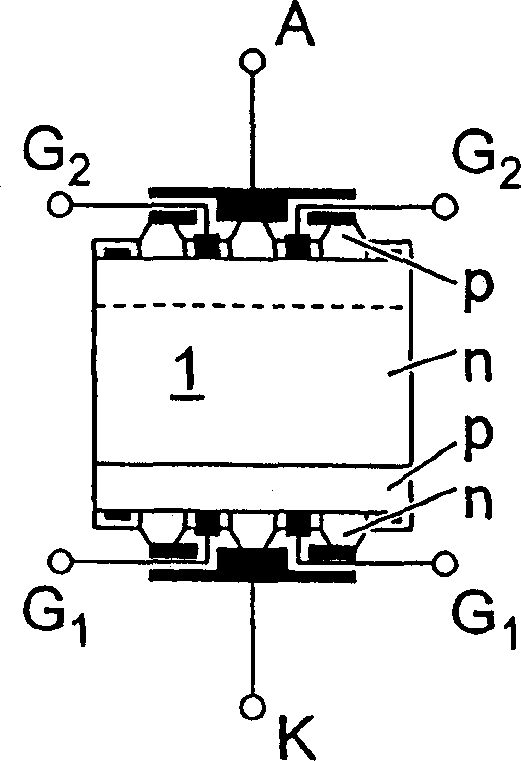

[0036] The integrated gate double transistor IGDT has a substrate with four semiconductor layers, on each side of which two electrical connections are provided.

[0037] figure 1 Diagrammatically showing the cross-section of this IGDT with four differently doped semiconductor layers,

[0038] - an anode layer with p-type doping outside the anode,

[0039] - a two-part n-type doped base layer with integrated n-type buffer,

[0040] - a p-type doped base layer, and also

[0041] - an n-type doped cathode layer outside the cathode.

[0042] There is a main connection terminal on both sides of the IGDT, anode A and cathode K, and a gate connection terminal, the first gate G 1 On the cathode side, the second gate G 2 on the anode side.

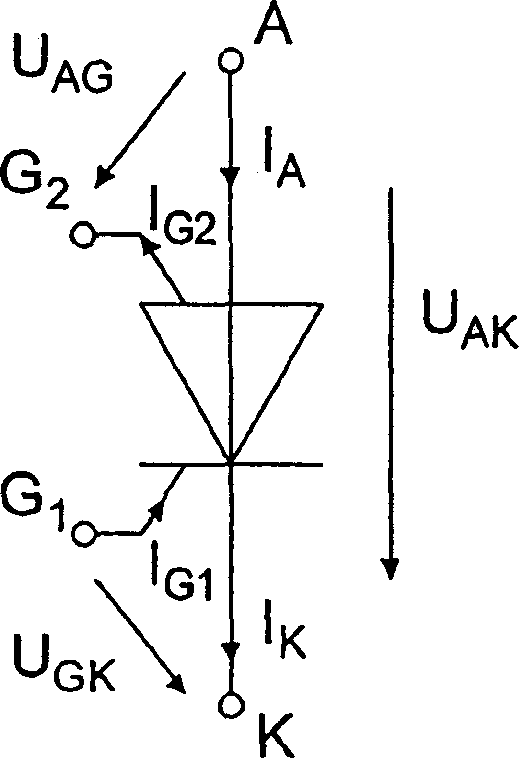

[0043] figure 2 The symbol of IGDT is shown. In this specification, positive values according to the direction of the arrows in this diagram are use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com