Middle power carbon dioxide laser tube

A carbon dioxide and laser tube technology, applied in the direction of lasers, laser components, laser components, etc., can solve the problems of difficult popularization and application, large gas consumption, high price, etc., to achieve increased control range, stable output power, and reduced excitation The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

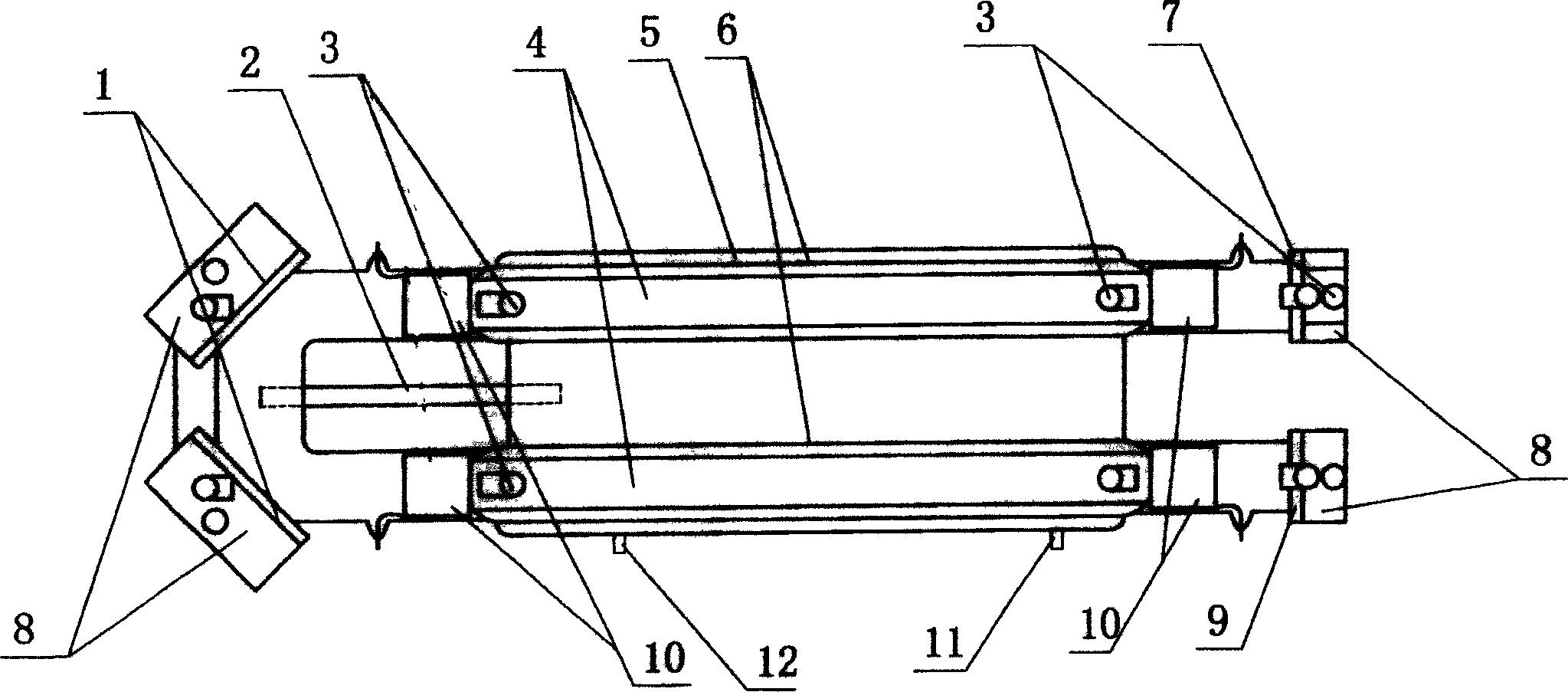

[0007] The accompanying drawings have shown the structure of the present invention and its embodiments, and the relevant details of the embodiments will be described in detail below in conjunction with the accompanying drawings. This small-volume medium-power laser tube has a discharge tube 4 and a water-cooled tube 6. The water-cooled tube 6 is sleeved on the discharge tube 4. A large gas storage tube 5 is arranged on the periphery of the discharge tube 4 and the water-cooled tube 6. The holes at both ends of the large gas storage tube 5 are burnt with the water-cooled tube 6, and the discharge tube 4 and the water-cooled tube 6 placed in the large gas storage tube 5 are provided with at least two groups, and the ends between the components are connected to the The tails are burnt together to form a V-shaped, H-shaped or W-shaped series optical path. In this embodiment, the discharge tube 4 and the water-cooled tube 6 in the large gas storage tube 5 are provided with two group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com