Electronic device and dielectric ceramic composition and its preparing method

A technology of dielectric ceramics and composites, applied in the field of multilayer capacitors or other electronic devices, can solve problems such as insufficient dielectric constant, and achieve the effects of small temperature dependence, improved dielectric constant, and small voltage dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

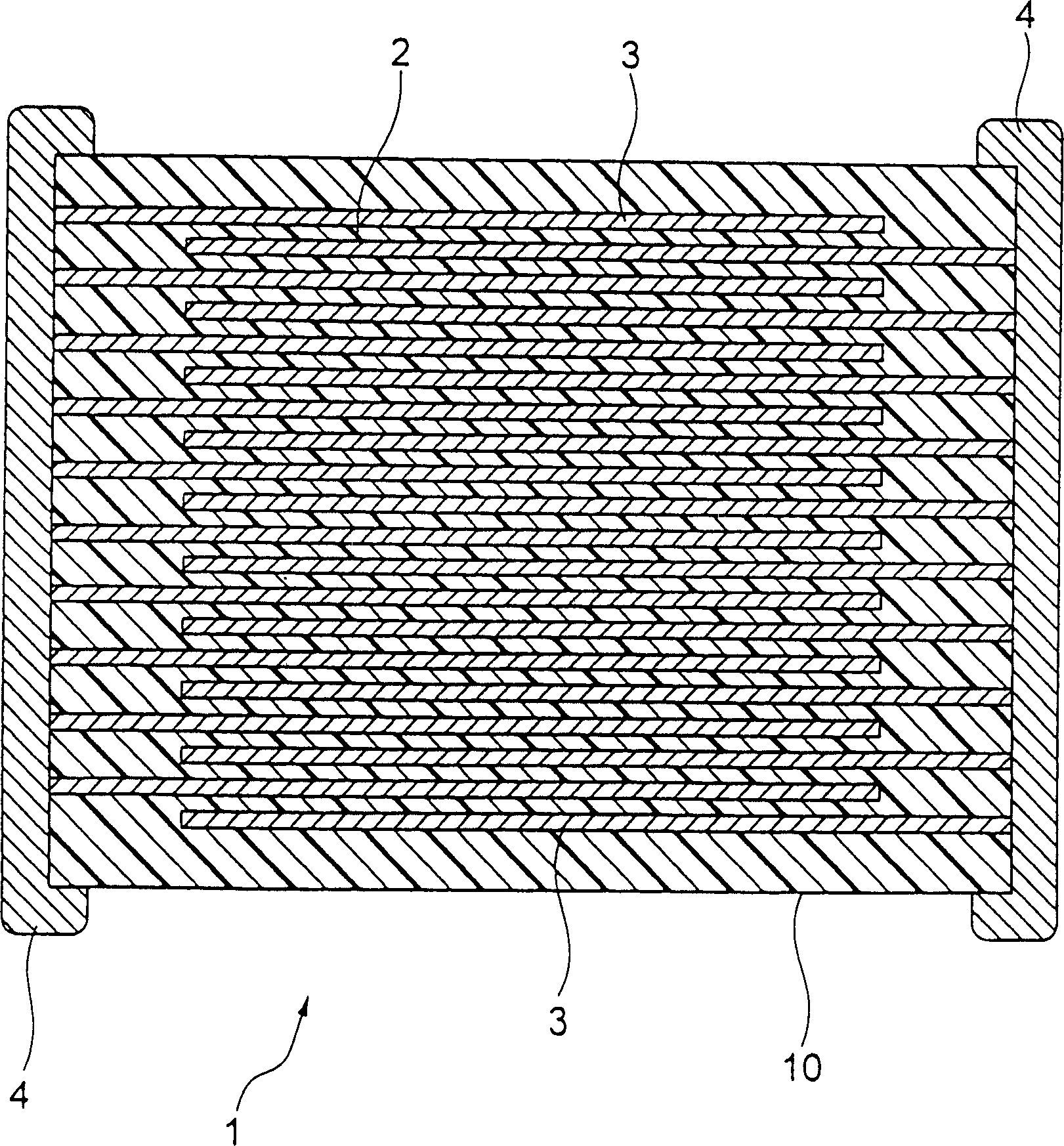

[0050] Manufacturing method of multilayer ceramic capacitor

[0051] The multilayer ceramic capacitor made of the dielectric ceramic composition of the present invention is made of a green chip by a general printing method or a sheet-making method using a paste, sinters the green chip, and then prints or transfers and calcines the external electrodes. The fabrication method will be described in detail below.

[0052] The dielectric layer paste may be an organic type paint obtained by mixing the dielectric layer components with an organic vehicle, and may be a water-based paint.

[0053] As for the dielectric component, the above-mentioned oxides or their mixtures or composite oxides can be used, but various compounds that form the above-mentioned oxides or composite oxides after sintering, such as carbonates, oxalates, can also be appropriately selected and mixed. , nitrates, hydroxides and organometallic compounds. The content of these compounds in the dielectric member is ...

Embodiment 1

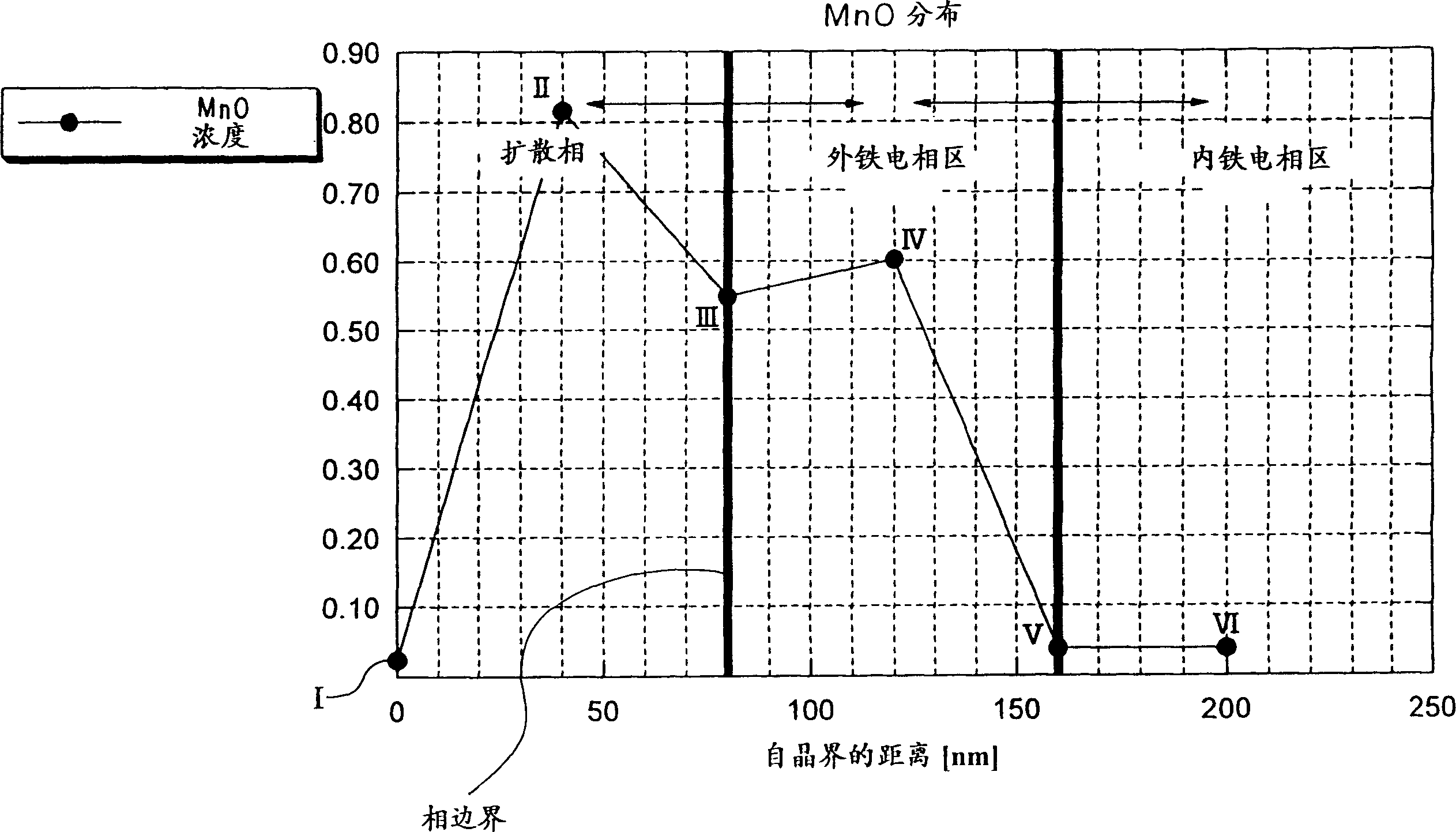

[0091] First based on the BaTiO 3 Consists of 100 mol% Barium Titanate (A), weighing 0.5 mol% MnCO 3 . It was mixed with pure water and ground for 16 hours in a ball mill with zircon balls. Next, let the mixture dry in a high-temperature oven at 130° C. to evaporate moisture. The dried resulting powder was calcined at 1100 °C to obtain BaTiO 3 and MnO mixture. Note that the calcination is performed in a reducing atmosphere or even in air.

[0092] Based on 100 mol% pre-calcined barium titanate (A), weigh 50 mol% post-added BaTiO 3 (B), 2.5 mol% MgCO 3 , 2.5 mol% of Y 2 o 3 , 1.5 mol% CaCO 3 and 4 mol% SiO 2 . Calcined BaTiO 3 The mixture with MnO was mixed with pure water and ground for 16 hours in a ball mill with zircon balls. Then the mixture was dried in a high-temperature oven at 130° C. to evaporate moisture to obtain a dielectric component.

[0093] Note that the particle sizes of the pre-calcined barium titanate (A) and the post-added barium titanate (B) ...

Embodiment 2-4

[0125] The same procedure as in Example 1 was followed, except that FeO, CoO or NiO was used instead of MnO as shown in Table 1 to prepare capacitor samples. These samples were tested in the same manner as in Example 1. As shown in Table 1, it was confirmed that the samples had superior characteristics similar to those of Example 1 in terms of dielectric constant (ε), temperature characteristics, voltage characteristics, dielectric loss (tanσ) and insulation resistance (IR).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap