Preparation process and apparatus for alpha-acetyl-gamma-butyrolactone

The technology of butyrolactone and acetyl group is applied in the field of preparation of α-acetyl-γ-butyrolactone and its special equipment, and can solve the problems of material punching, combustion and explosion, difficulty in recycling by-products, intractable waste water and the like, Achieving the effects of less pollution, good economic benefits, and gentle neutralization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the method for producing α-acetyl-γ-butyrolactone, relative to γ-butyrolactone, 1.6 to 1.8 equivalents of ethyl acetate, 0.2 to 0.3 equivalents of alkali metal, 1.0 to 1.4 of benzene solvent and 1.1 to 1.4 1.4 equivalents of phosphoric acid; this embodiment uses 500KG of gamma-butyrolactone, 138KG of sodium metal, 850KG of ethyl acetate, and 600KG of toluene. The whole process is divided into reaction section, neutralization section and distillation section, the specific operation is as follows:

[0026] In the reaction stage, put the solvent toluene into the reaction kettle first, then put in 138KG of sodium metal, heat to 100-105°C, stir for 15 minutes, then quickly cool to 65°C, wait for sodium sand to form at the bottom of the kettle, and then add γ-butyrolactone and For the mixture of ethyl acetate, the temperature is controlled at 65-92°C. After the dropwise addition, the temperature is controlled at 80-85°C, and the temperature is kept at 10 hours; then the so...

Embodiment 2

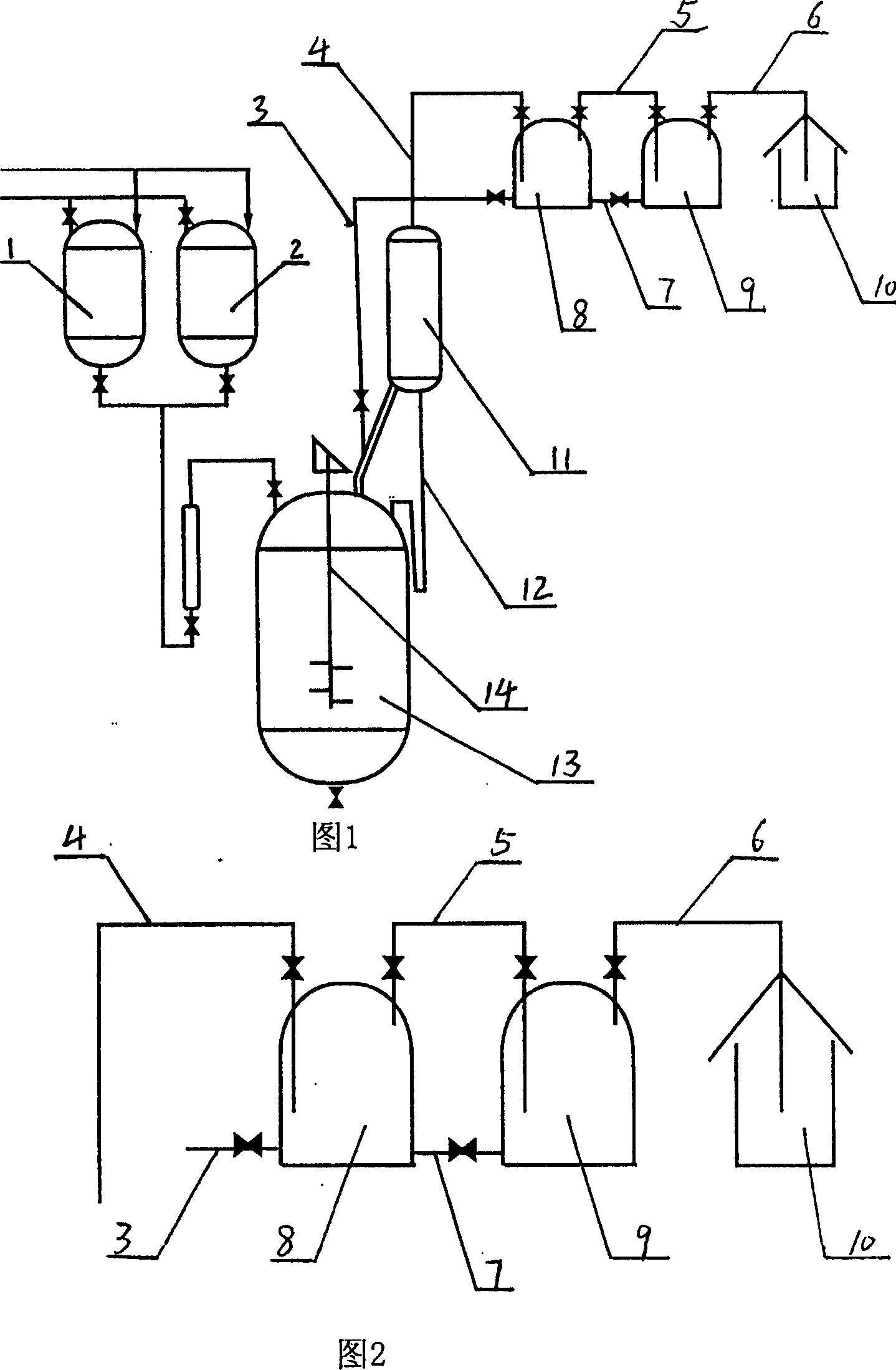

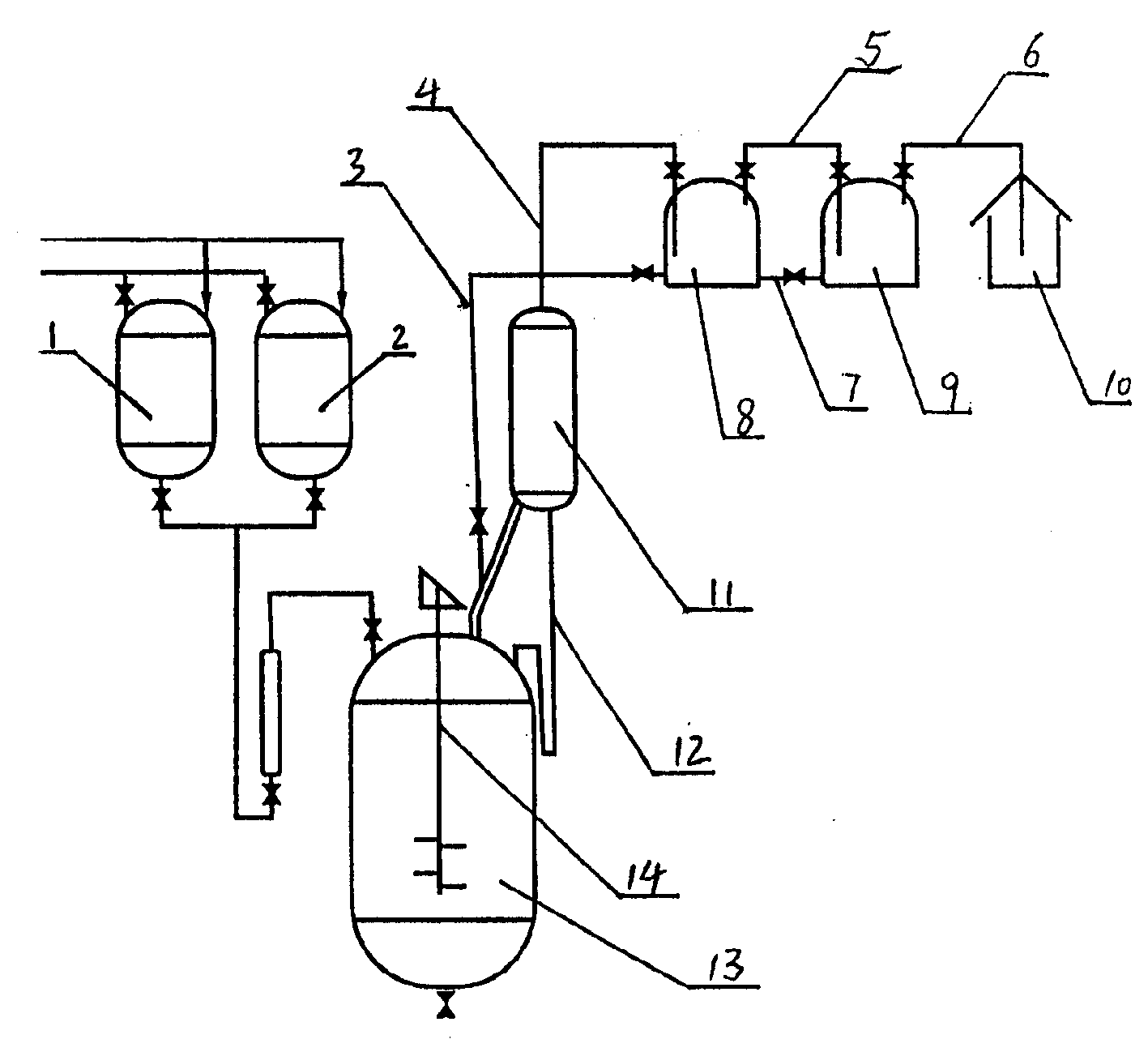

[0029] In conjunction with Fig. 1, the special-purpose reactor of the present embodiment is described, the reactor of the present embodiment, the buffer reflux tank and the recovery tank are made of special stainless steel, and a group of buffer reflux devices are arranged above the reactor (13). It consists of two buffer return tanks (8, 9) and a recovery tank (10). The top of the two buffer return tanks is connected by a pipe (5), and the bottom is connected by a return pipe (7). Among them, the buffer return tank (9) Link to each other with the top of recovery tank (10) by pipeline (6); Another buffer reflux tank (8) top links to each other by pipeline (4) and condenser (11), and the bottom is provided with return pipe (3) and reactor (13 ) is connected; its function is that if there is improper operation, or when the reaction is difficult to control, a large amount of metal sodium sand will run out with the solvent, which will cause a great safety hazard, because metal sodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com