Plane strain measurement sensor

A technology for measuring sensor and plane strain, applied in the direction of mechanical solid deformation measurement, material inspection products, etc., can solve the problems of inability to test, large influence of strain data, etc., to improve output stability, small influence of temperature change, and small linear error. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

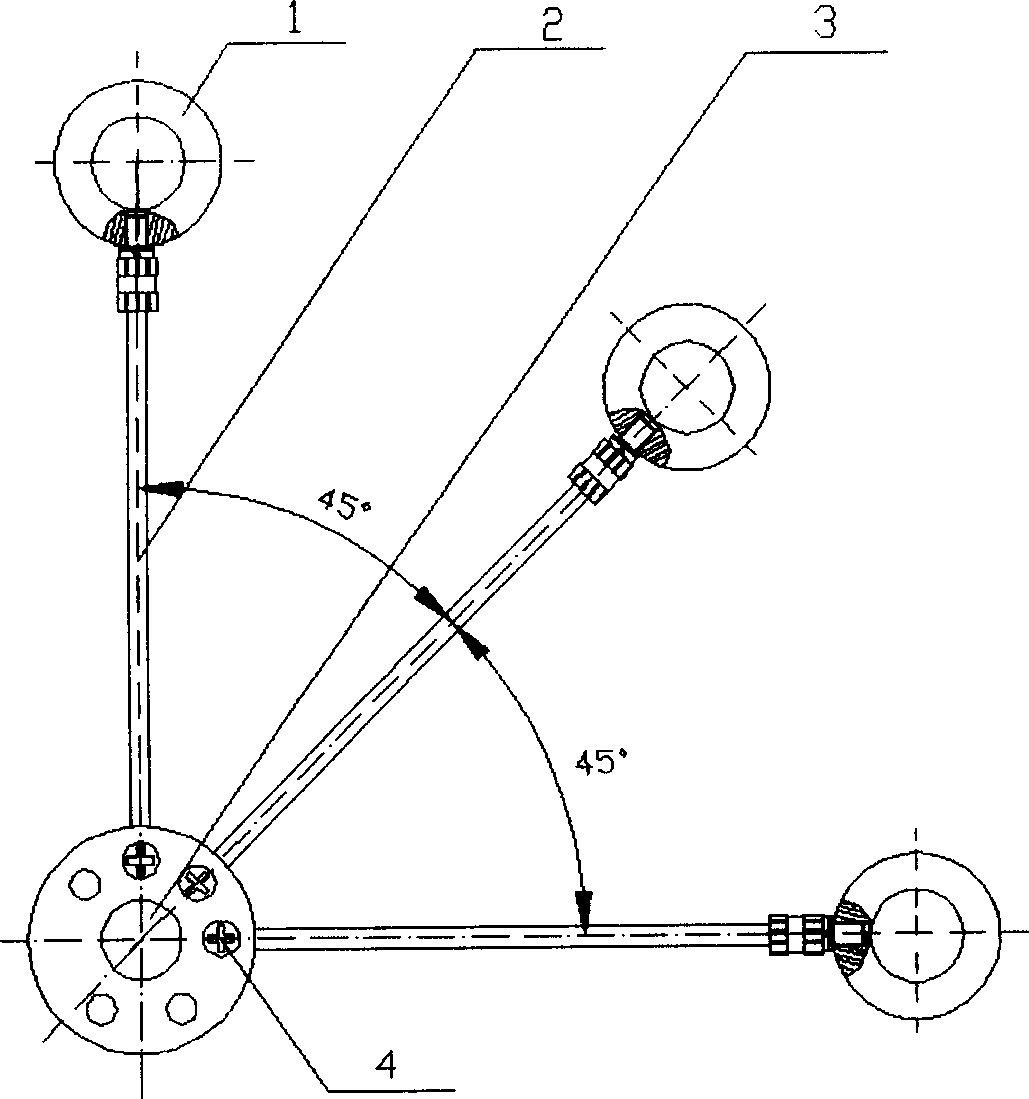

[0021] figure 1 A schematic structural diagram of an embodiment of the 45° right-angle plane strain measuring sensor of the present invention is given. exist Figure 1-6 Among them, the plane strain measurement sensor of the present invention is composed of a sensor 1, a connecting rod 2, a multidirectional support 3, and a limiting screw 4.

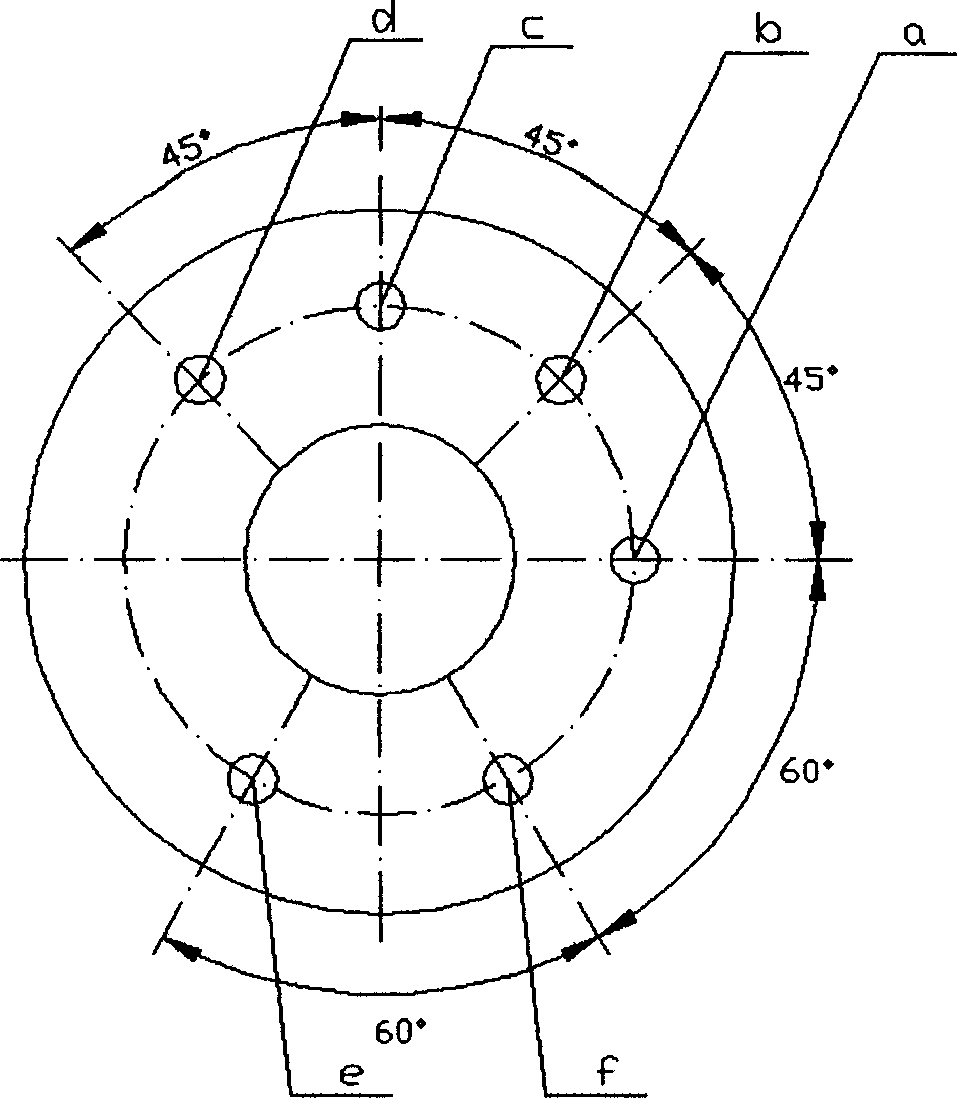

[0022] The shape of the multidirectional pillar 3 of the present embodiment is a cylinder, and a center hole is processed in the center of the multidirectional pillar 3, and a, b, c, d, e are sequentially processed in the axial direction on the upper surface of the multidirectional pillar 3 , f six screw holes can also be processed into positioning slot holes, the central angle between a screw hole and b screw hole, b screw hole and c screw hole, c screw hole and d screw hole is 45°, d screw hole The central angle between screw hole e and screw hole e is 105°, the central angle between screw hole e and screw hole f is 60°, and the cent...

Embodiment 2

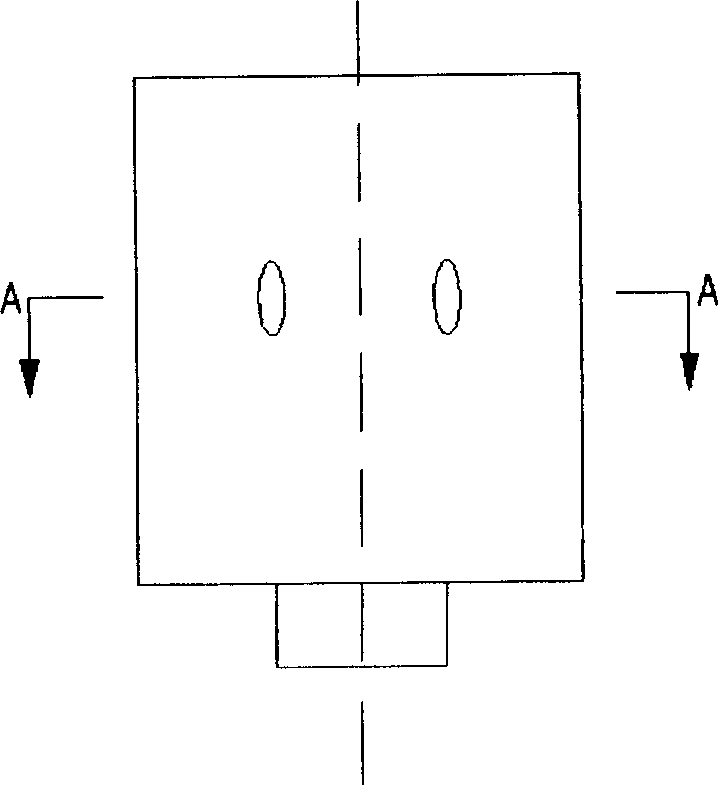

[0037] exist figure 2 , 3 , 4, 7, the plane strain measurement sensor of the present embodiment is connected by multi-directional pillar 3, four connecting rods 2, four sensors 1, and limiting screw 4 into a fan-shaped plane strain measurement sensor. In the screw holes a, b, c, and d on the upper surface of the multi-directional pillar 3, limit screws 4 are installed to fix and install the four connecting rods 2 on the sides of the multi-directional pillar 3 facing a', b' in the same plane. , c', d' holes, a sensor 1 is connected to the other end of each connecting rod 2 to form a fan-shaped plane strain measurement sensor, and each sensor 1 is connected to a strain gauge through a cable. The structures of the sensor 1 and the multi-directional support 3 are the same as those of the first embodiment. The fan-shaped plane strain measurement sensor of this embodiment is suitable for measuring the strain value of the measured part of the component when the principal strain or...

Embodiment 3

[0048] exist figure 2 , 3 , 4, 8, the plane strain measuring sensor of the present embodiment is to be connected into 60 ° equiangular plane strain measuring sensor by multi-directional pillar 3, three connecting rods 2, three sensors 1, limit screw 4. In the a, e, f screw holes on the upper surface of the multi-directional pillar 3, limit screws 4 are installed to fix the three connecting rods 2 respectively on the a', e', f' in the same plane on the side of the multi-directional pillar 3. In the hole, a sensor 1 is connected to the other end of each connecting rod 2, and each sensor 1 is connected with a strain gauge through a cable to form a 60° equiangular plane strain measurement sensor. The structures of the sensor 1 and the multi-directional support 3 are the same as those of the first embodiment. The 60° equiangular plane strain measurement sensor of this embodiment is suitable for measuring the strain value of the measured part of the component when the principal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com