Oxide cathode for picture tube

A technology of oxide cathode and kinescope, which is applied in the field of kinescope to achieve the effect of increasing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

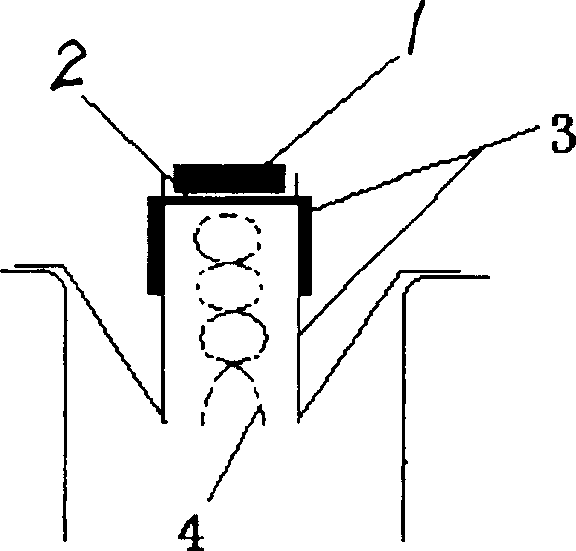

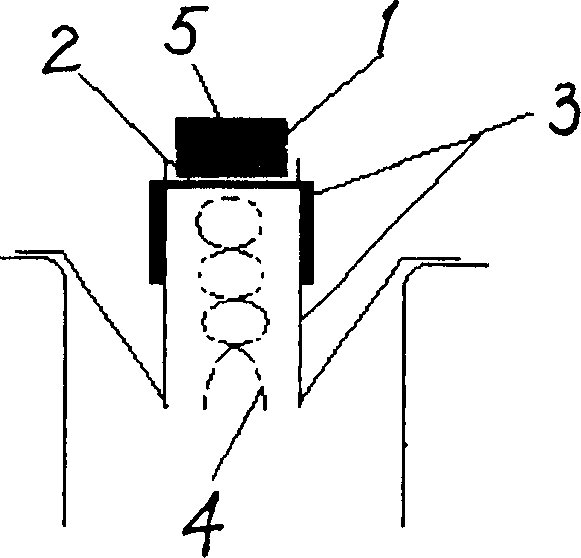

[0026] see figure 2 , a kind of oxide cathode for kinescope of the present invention comprises base metal 2 and sleeve 3, sleeve 3 and base metal 2 press-fit combination, base metal 2 is Ni material containing a small amount of activator Mg and Si, sleeve 3 has One or two inside and outside.

[0027] Below the base metal 2 , ie in the sleeve 3 , a heating element 4 is housed. An electron emission layer 1 is sprayed on the base metal 2 . There is also a second electron emission layer 5 on the first electron emission layer 1 , that is, two layers of electron emission layers 1 and 5 containing different components are sprayed sequentially on the base metal 2 .

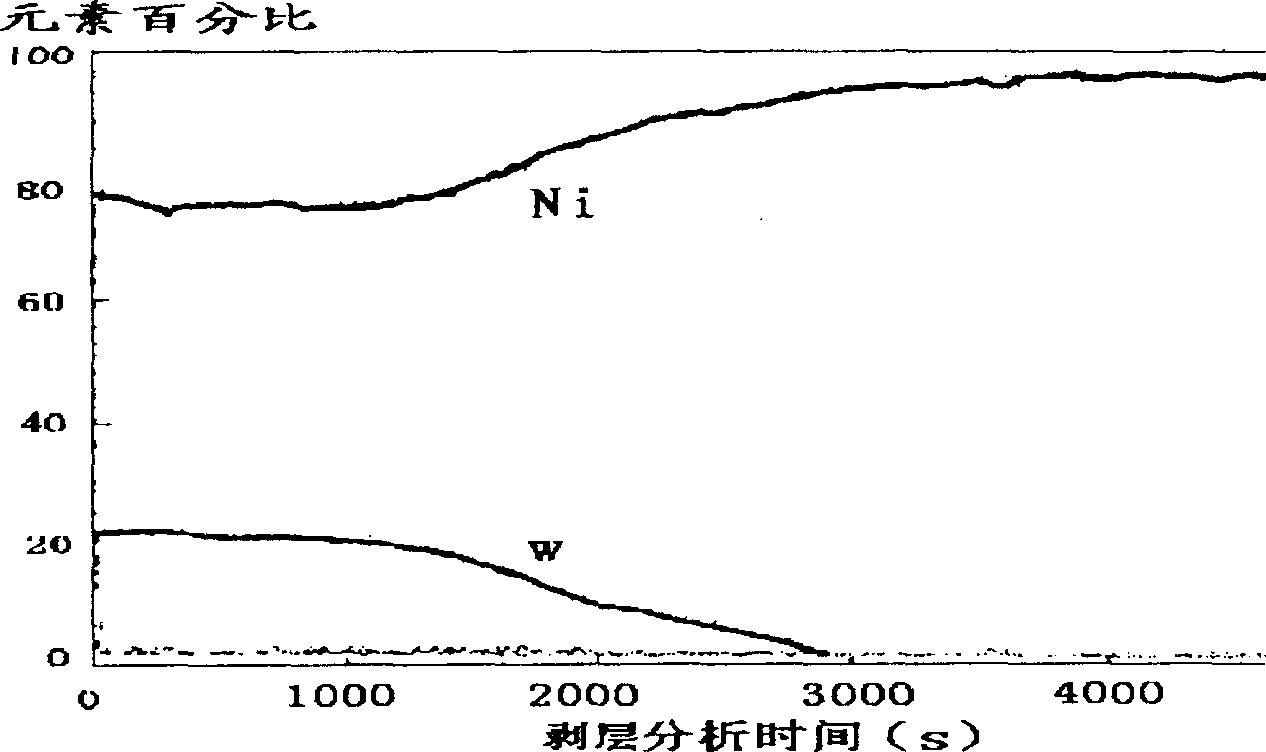

[0028] The first layer of electron emission layer 1 is based on the main component alkaline earth metal oxide doped with two types of metal powder, one of which is Ni powder without reducing ability, and the other is W with reducing ability. pink. The alkaline earth metal oxides in the first electron emission layer 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com