Ternary composite microsphere formulation and its preparation method

A technology of composite microspheres and microcapsules, which is applied in the field of pharmacy, can solve the problems of activity change and difficulty in improving the encapsulation rate, and achieve the effect of improving the encapsulation rate, good drug release mode, and reducing incomplete release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of preparation method of composite microsphere of the present invention

[0030] (1) Preparation of calcium alginate microcapsules: using BSA as a model drug, dissolve BSA with a small amount of distilled water and mix well with 1% sodium alginate solution. The first emulsifier is Span 80, which is soluble in isooctane 5% (w / v), the volume ratio of the two phases is 1:2, the high-speed milking speed is 12000rpm, and the time is 3 minutes, then add the second emulsifier, namely Tween 80, and the concentration is 30% (w / w) , the dosage is 45% of Span 80, and then milk for 3 minutes, add cross-linking agent calcium chloride solution, the concentration is 8% (w / v), and then milk for 3 minutes, add isopropanol to separate out the extraction of microcapsules The time is 2 minutes. Calcium alginate microcapsules were prepared after centrifugation.

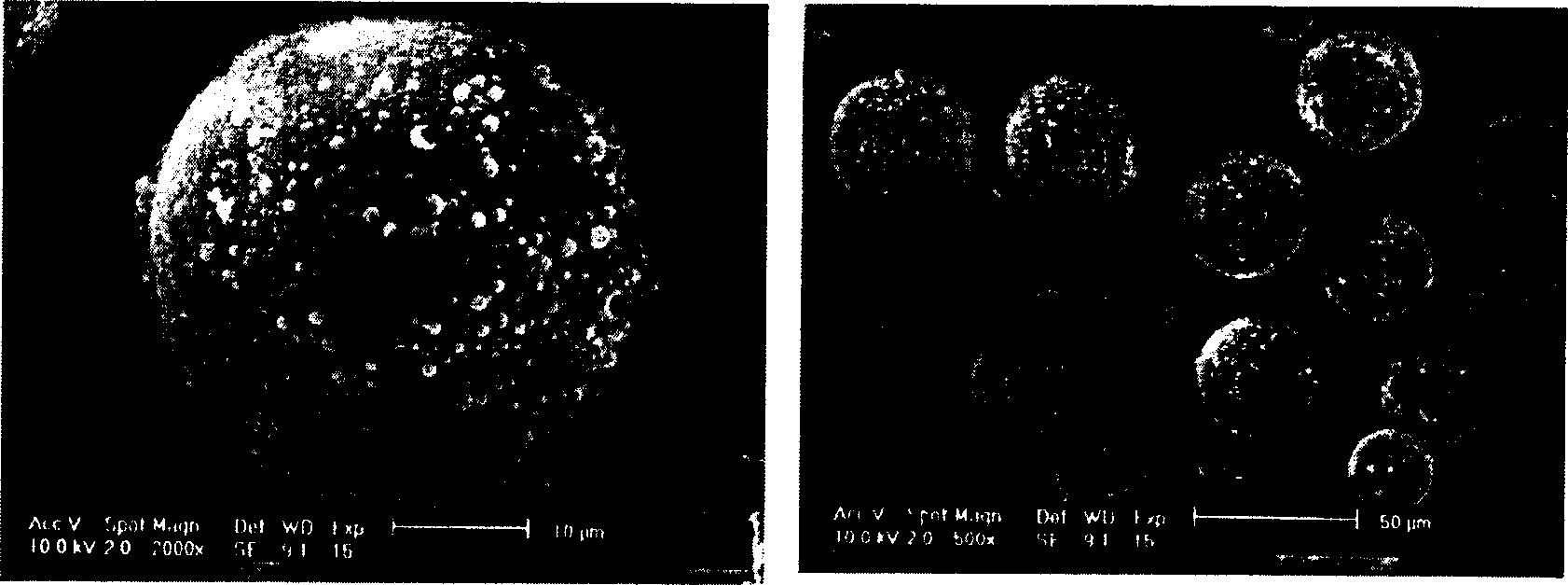

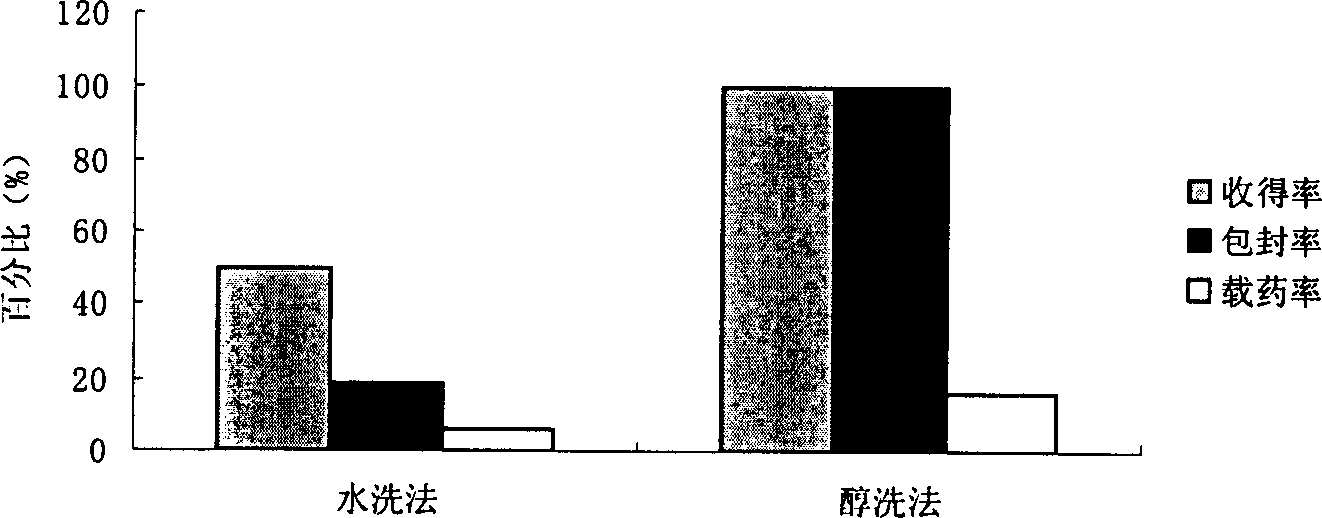

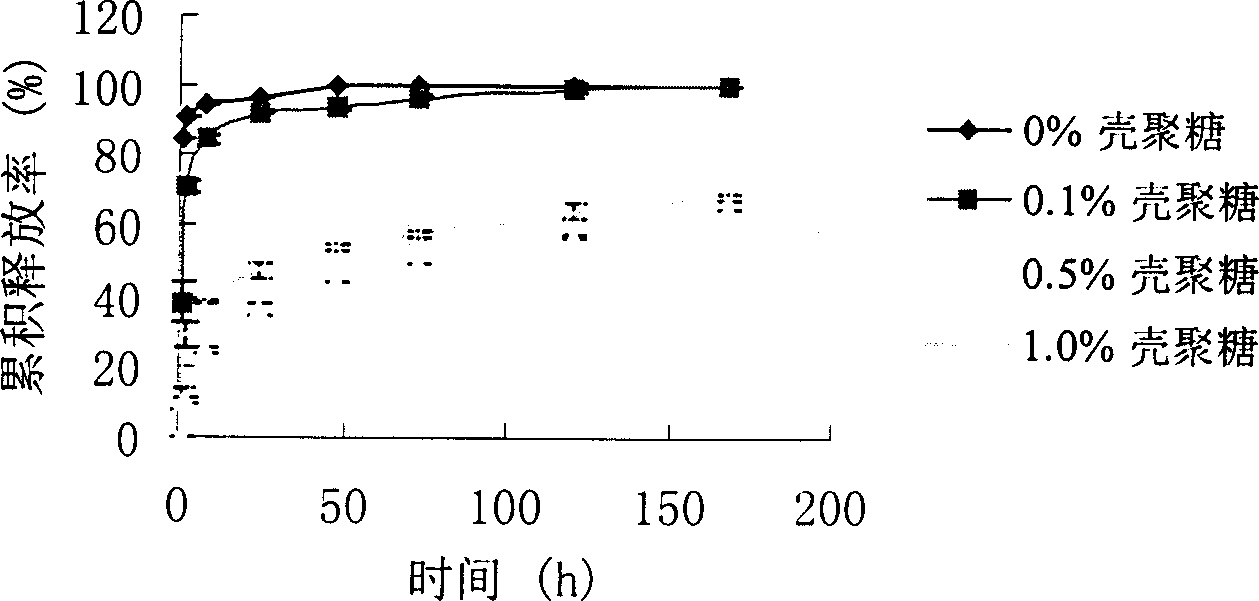

[0031] (2) Preparation of calcium alginate-chitosan microspheres: the calcium alginate microcapsules prepar...

Embodiment 2

[0034] Embodiment 2 The second preparation method of composite microspheres of the present invention

[0035] The rotational speed of the two-phase high-speed emulsion in the first step is 5000rpm; the particle size of the double-layer composite microcapsules obtained in the second step is <8 μm; the particle size of the microspheres obtained in the third step is <50 μm; the rest of the steps are the same as in Example 1.

Embodiment 3

[0036] Embodiment 3 The 3rd kind of preparation method of composite microsphere of the present invention

[0037] In the first step, the rotation speed of the two-phase high-speed emulsion is 20000rpm, the particle size of the double-layer composite microcapsules obtained in the second step is <2 μm, and the particle size of the microspheres obtained in the third step is <30 μm, and the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com