High-performance CuCr25 alloy contact materials and rapid solidifying preparation

A technology for vacuum circuit breaker and contact material, which is applied in the field of preparation of CuCr alloy bulk material for high-power vacuum circuit breaker switch contact material, can solve the problems of high cost, low yield, and difficulty in obtaining high-quality contact material. , to achieve the effect of high withstand voltage, breakdown resistance, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

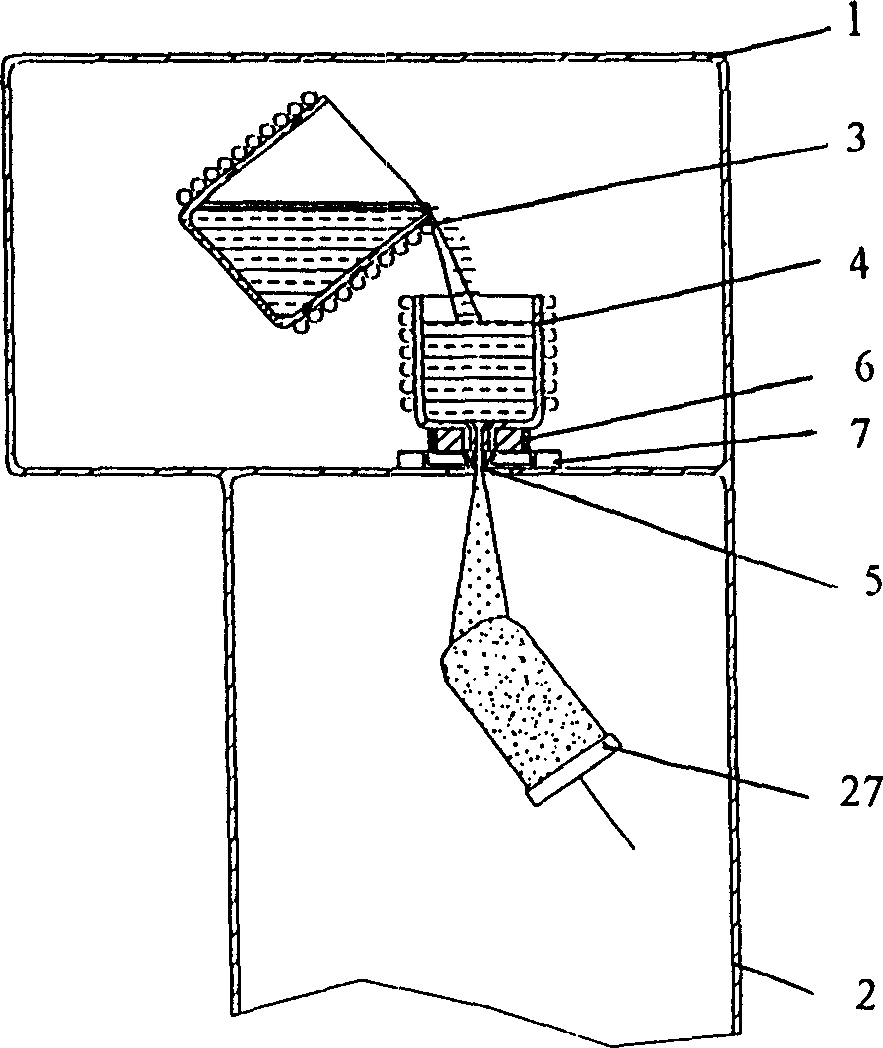

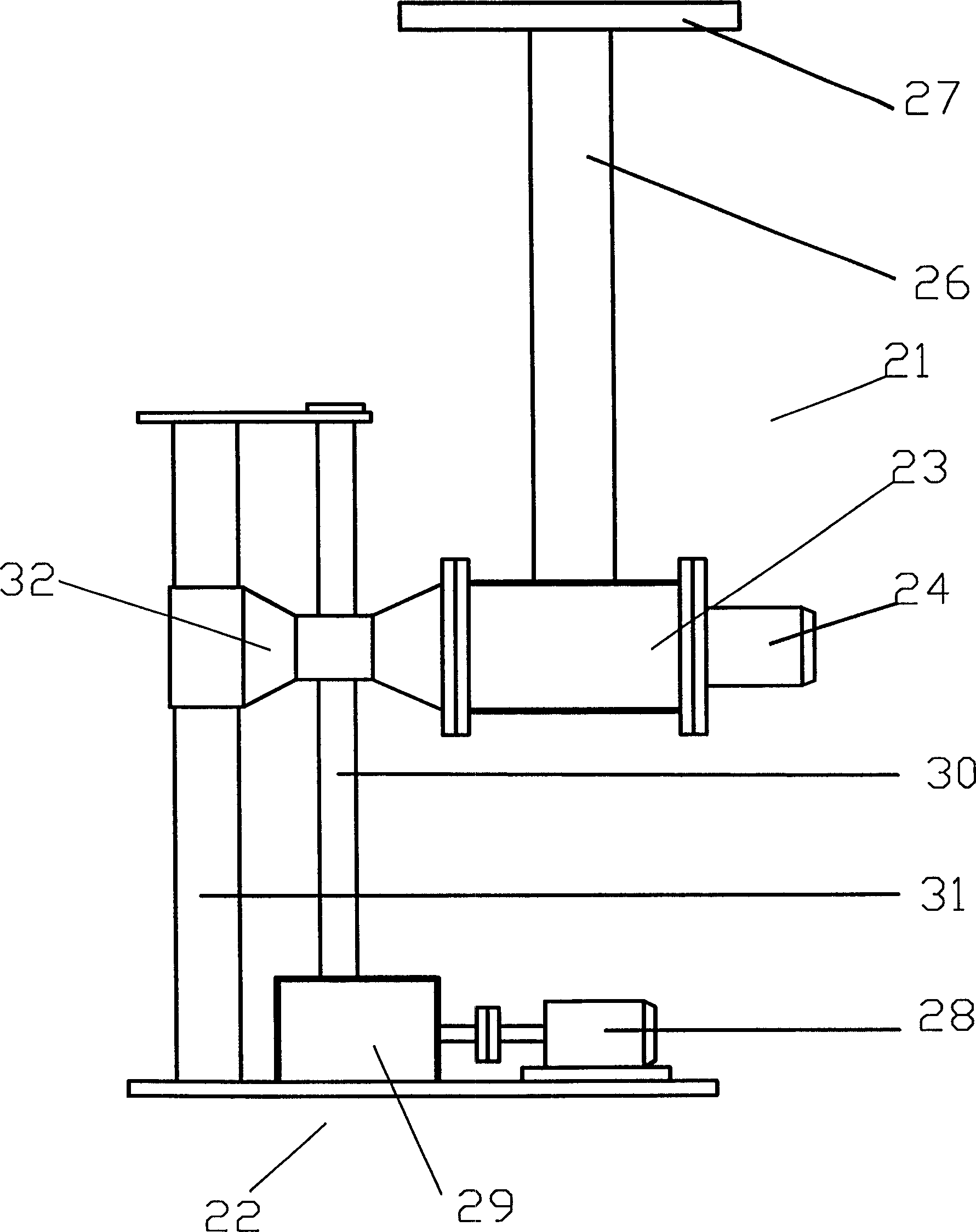

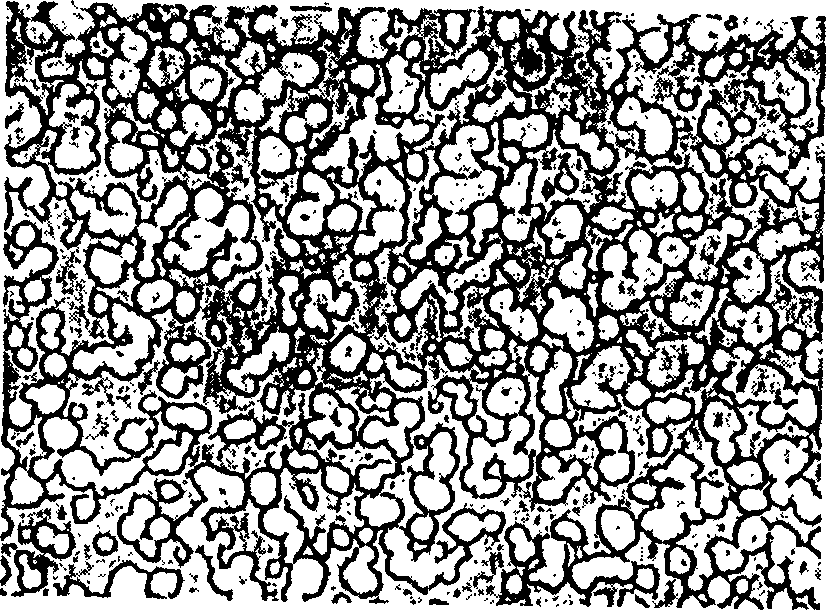

[0035] According to the alloy composition, by weight percentage, the alloy composition is Cu75wt%, Cr25wt%, and the ingredients are mixed; under the protection of inert gas, the above raw materials are put into the temperature to 2100 °C to melt the raw materials and cast them into prefabricated ingots; prepare alloy prefabricated ingots Later, if figure 1 As shown, first vacuumize the melting tank body 1, and the vacuum degree is 10 -3 pa, and then filled with high-purity argon gas to normal pressure, under the protection of inert gas, the alloy prefabricated ingot was melted in the induction heating melting furnace 4, the temperature of the induction heating melting furnace 4 was controlled at 2300 ° C, and kept for 10 minutes; The heating tundish 6 is heated, and the temperature of the induction heating tundish 6 is controlled at 2100° C., and the molten melt passes through the guide tube 5 , and the temperature of the guide tube 5 is controlled at 2100° C. High-purity arg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com