Capacitor device in AC generator and mfg. method thereof

A technology of alternator, manufacturing method, applied in the field of capacitor devices, capable of solving problems such as poor insulation, longer manufacturing time, and peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0048]

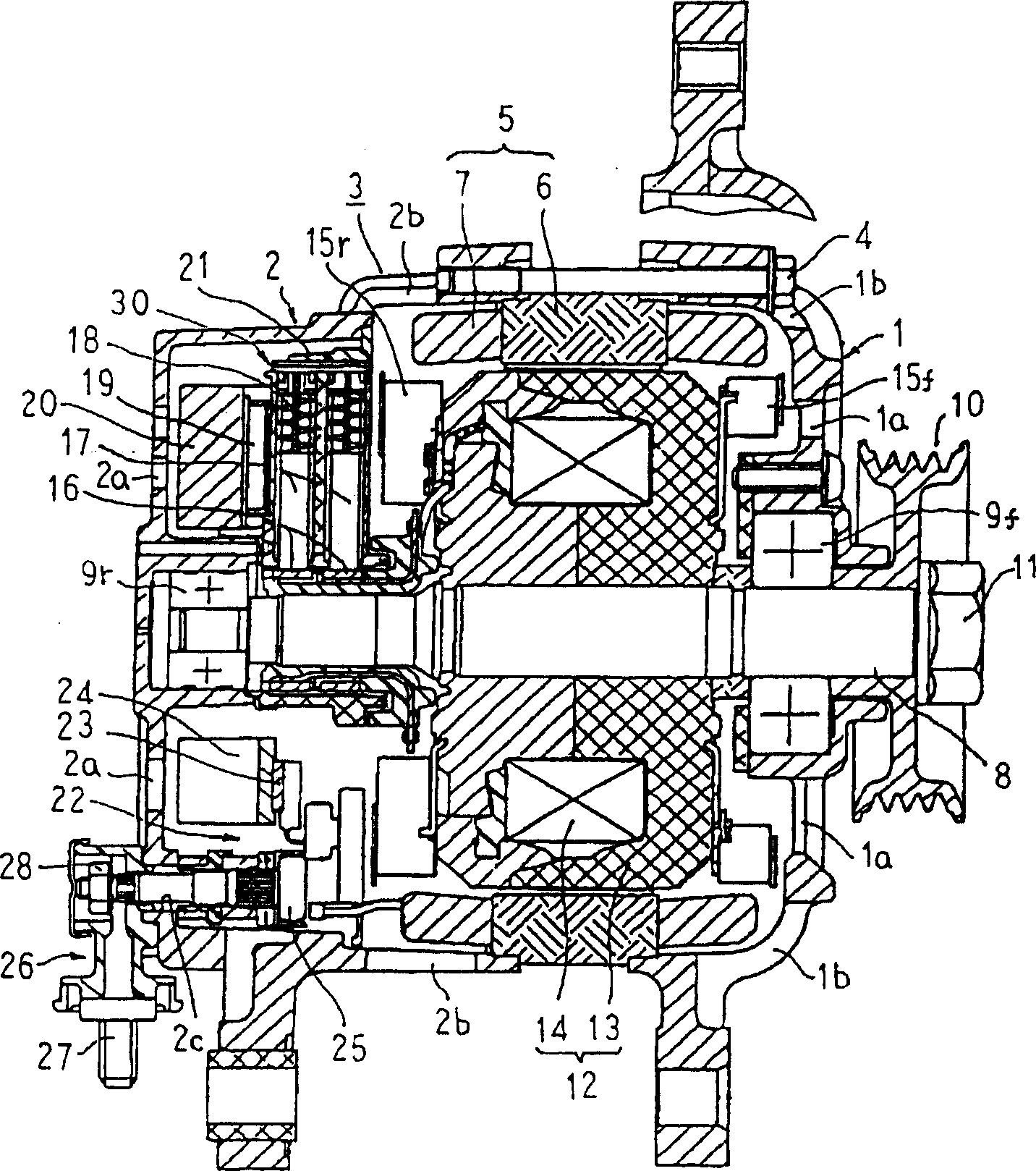

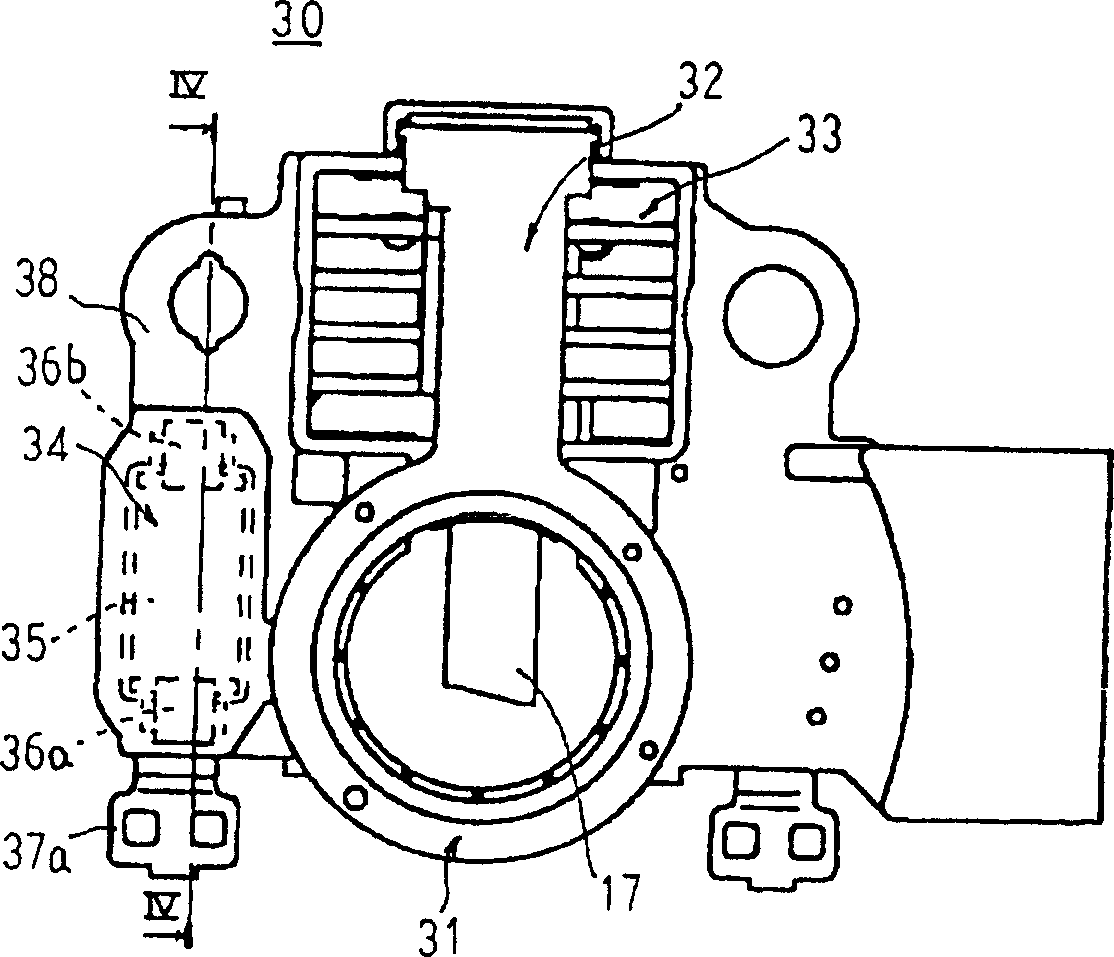

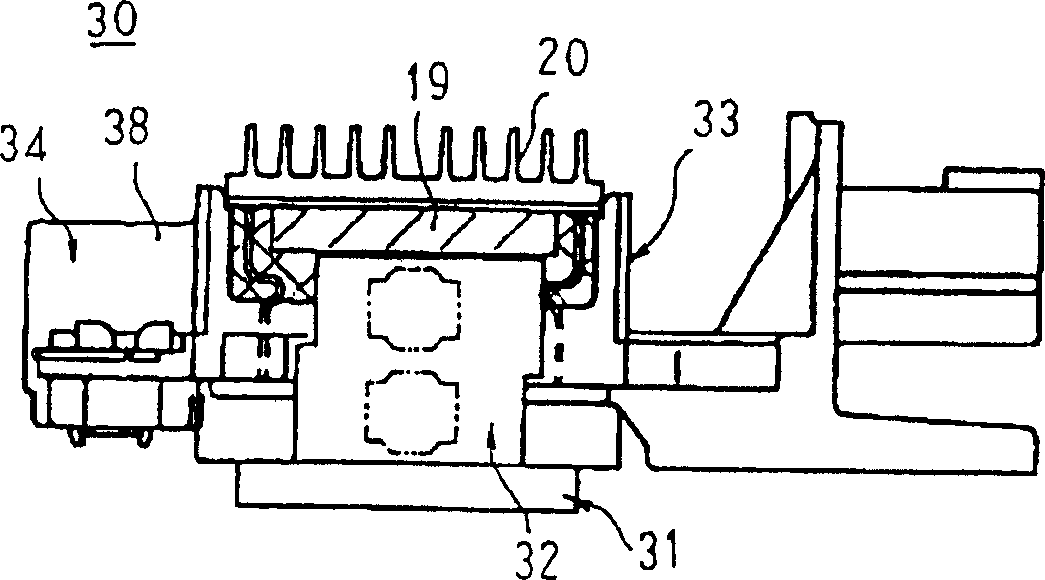

[0049] figure 1 is a longitudinal sectional view showing an alternator equipped with a capacitor device according to Embodiment 1 of the present invention, figure 2 It is a front view of the capacitor device of the alternator according to Embodiment 1 of the present invention seen from the front side, image 3 It is a side view showing the capacitor device of the alternator according to Embodiment 1 of the present invention, Figure 4 yes figure 2 Sectional view of IV-IV direction, Figure 5 It is a process drawing explaining the manufacturing method of the capacitor|condenser device of the alternator which concerns on Embodiment 1 of this invention.

[0050] figure 1 Among them, the generator casing 3 is a structure in which an aluminum front bracket 1 and a rear bracket 2 are combined into a palm shape, and are fastened and integrated by through bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com