Layered absorbent structure with zoned basis weight

A basis weight, basic layer technology, applied in the direction of layered products, absorbent pads, medical science, etc., can solve the problem that the moisture-absorbing core is not enough to achieve performance goals, and achieve rapid acquisition and absorption of liquid, increased absorption rate, and low bulk density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

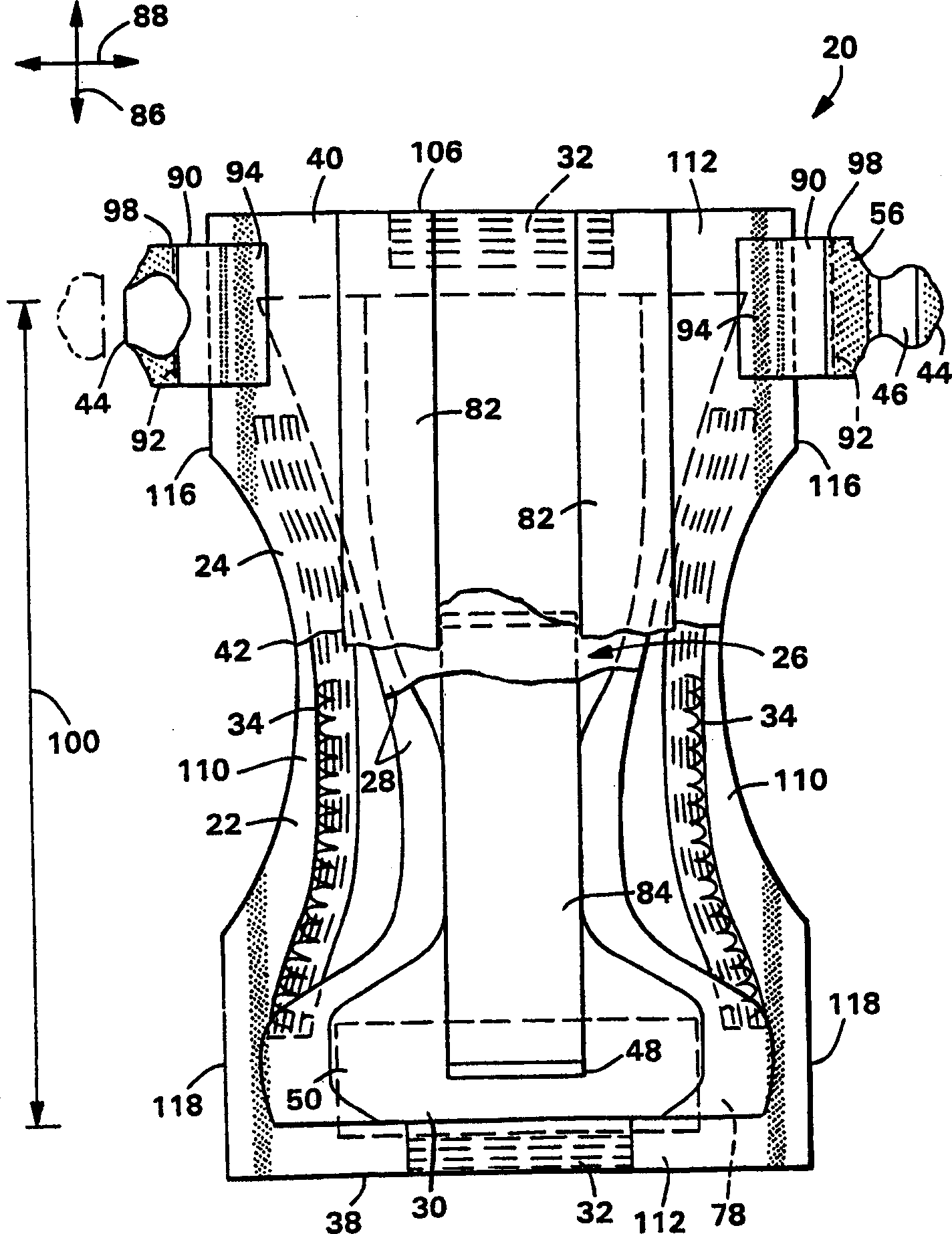

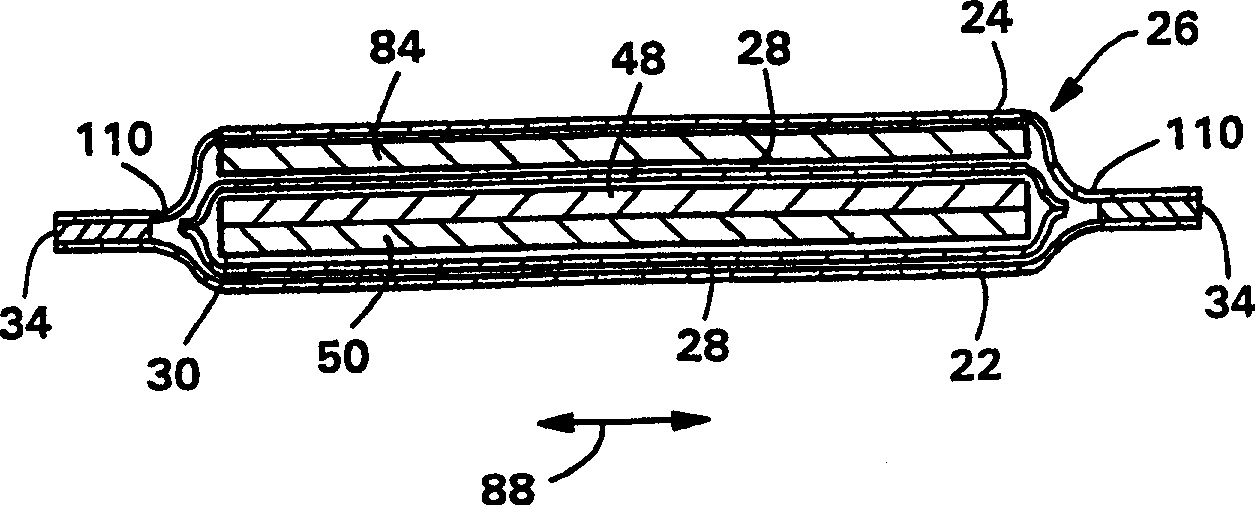

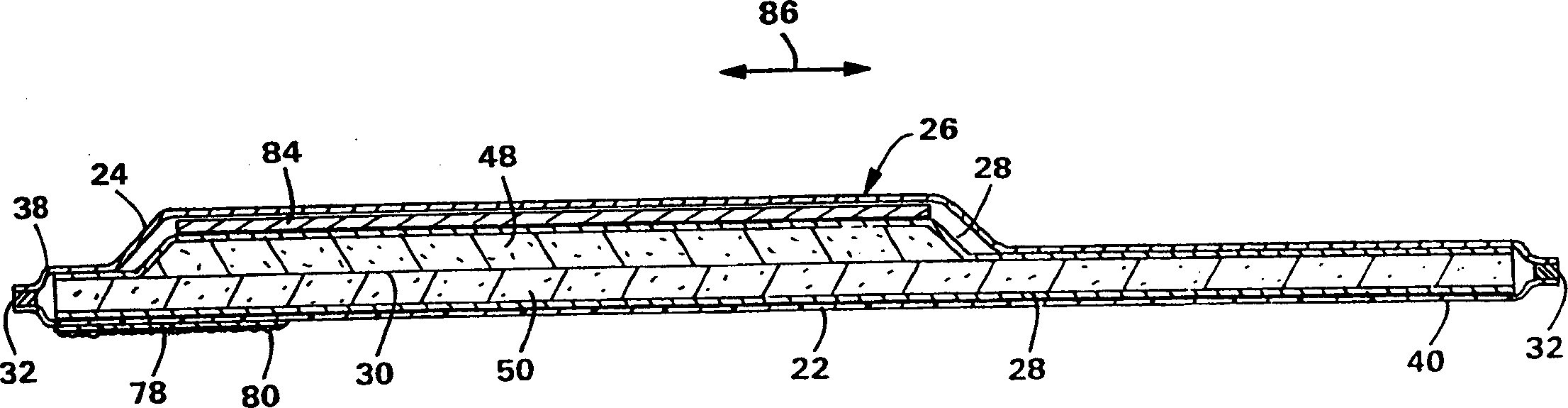

[0356] The bodyside layer had a basis weight of 500 gsm and comprised 50% 53C superabsorbent, a superabsorbent commercially available from Dow Chemical, and 50% HPF2 mercerized pulp, a material commercially available from Buckeye Corp. The tau value for Dow 53C superabsorbent is 8.5 minutes; the capacity for FAULZ is 33 g / g; and the 0.3 psiMAUL value is 26.2 g / g. like image 3 and 3A As shown, the bodyside layer extends over the area of the 48 layer region and is densified to 0.2 g / cc.

[0357] The outer layer in the area covered by the bodyside layer 48 has a basis weight of 200 gsm and the remaining area has a basis weight of 500 gsm, the total area covering the entire pad-shaped area (area of layer area 50). This material consisted of 25% SXM880 superabsorbent, a superabsorbent available from Stockhausen, and 75% CR-1654 fluff pulp available from Alliance Forest Products, a company located in Coosa Pines, Al. SXM 880 superabsorbent has a tau value of 4 minutes; FAULZ...

example 2

[0361] The bodyside layer had a basis weight of 336 gsm and was comprised of 75% 53C superabsorbent, a superabsorbent available from Dow Chemical, and 25% HPF2 mercerized pulp, a material available from Buckeye Corp. The tau value for Dow 53C superabsorbent is 8.5 minutes; the capacity for FAULZ is 33 g / g; and the 0.3 psiMAUL value is 26.2 g / g. like image 3 and 3A As shown, the bodyside layer extends over the area of the 48 layer region and is densified to 0.2 g / cc.

[0362] The outer layer has a basis weight of 300 gsm in the area covered by the bodyside layer 48 and a basis weight of 342 gsm in the remaining area which covers the entire pad-shaped area (area of layer 50). This material is comprised of 20% SXM 880 superabsorbent, a superabsorbent available from Stockhausen, and 80% CR-1654 fluff pulp, available from Coosa Pines, Al-Alliance Forest Products. SXM 880 Superabsorbent The τ value of the hygroscopic agent is 4 minutes; the FAULZ capacity is 388 / g; the 0.3 p...

example 3

[0365] The bodyside layer had a basis weight of 502 gsm and comprised 60% 53C superabsorbent, a superabsorbent available from Dow Chemical, and 40% HPF2 mercerized pulp, a material available from Buckeye Corp. The tau value for Dow 53C superabsorbent is 8.5 minutes; the capacity for FAULZ is 33 g / g; and the 0.3 psiMAUL value is 26.2 g / g. like image 3 and 3A As shown, the bodyside layer extends over the area of the 48 layer region and is densified to 0.2 g / cc.

[0366] The outer layer has a basis weight of 200 gsm in the area covered by the bodyside layer 48 and a basis weight of 435 gsm in the remaining area which covers the entire pad-shaped area (the area of layer area 50). This material was composed of 25% SXM880 superabsorbent, a superabsorbent available from Stockhausen, and 75% CR-1654 fluff pulp, available from Alliance Forest Products, a company located in Coosa Pines, Al. SXM 880 superabsorbent has a tau value of 4 minutes; a FAULZ capacity of 38 g / g; and a 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com