Reciprocating rotary piston system and pressure pump and IC engine using same

A reciprocating rotation and rotary power technology, which is applied in the direction of rotary piston engines, rotary or swing piston engines, swing piston pumps, etc., can solve the problems of shortened life, unavoidable piston force or reaction force, excessive wear, etc., to achieve Vibration and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

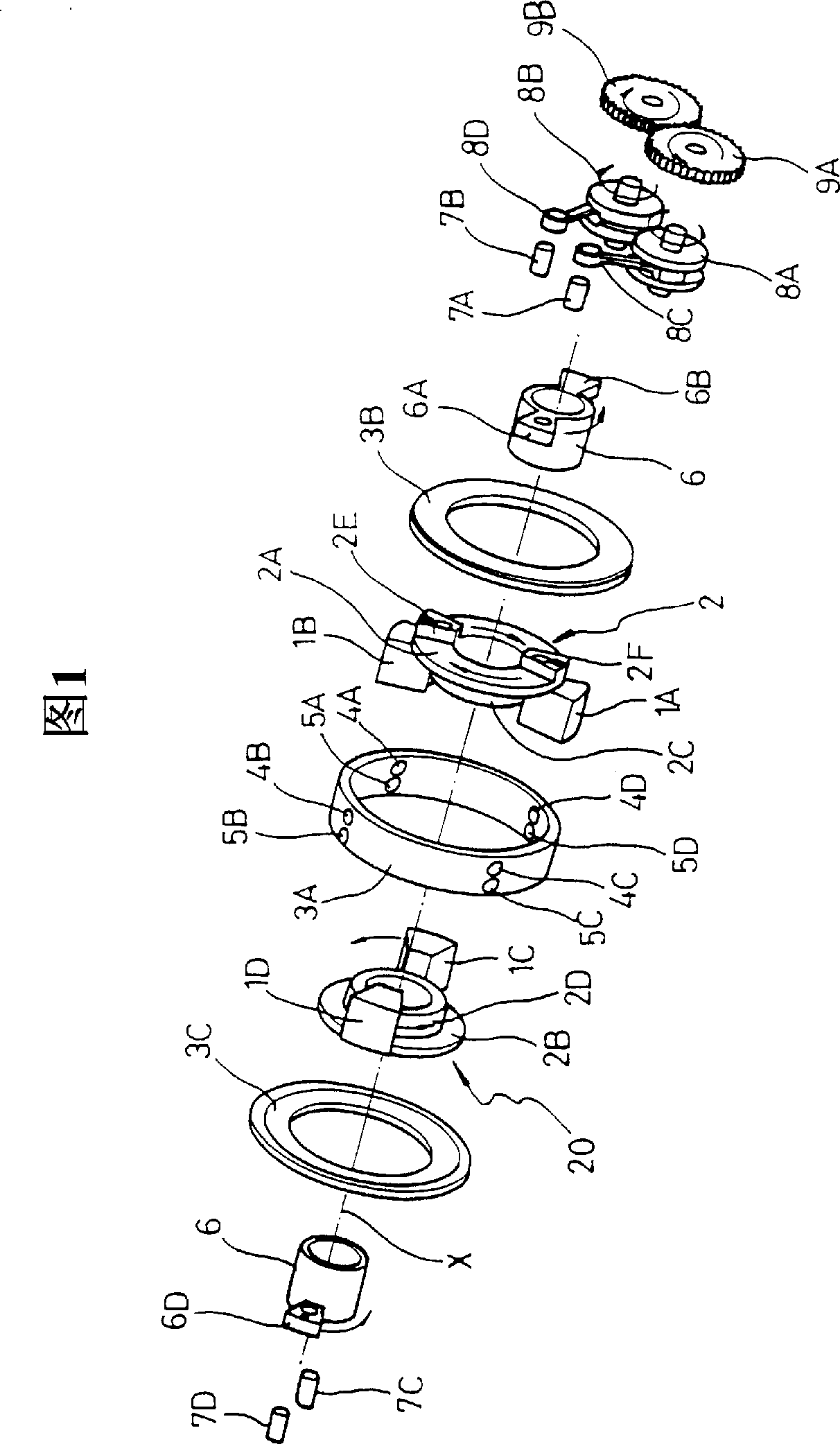

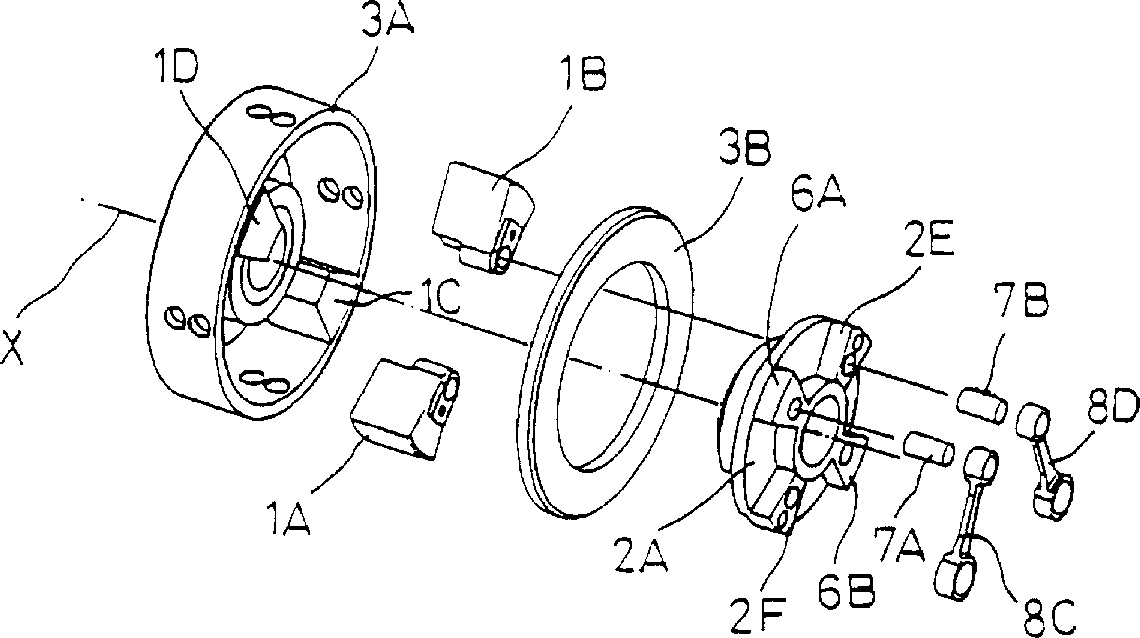

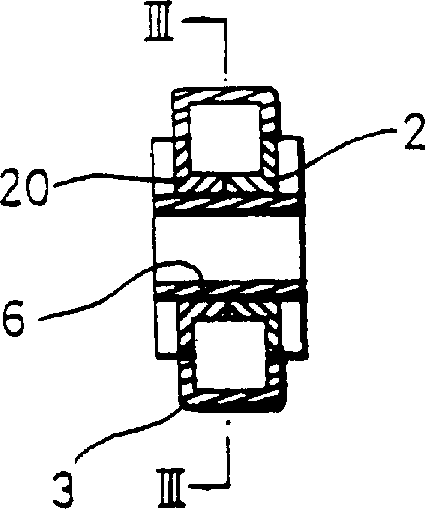

[0028] First please refer to Fig. 1 to Fig. 3, according to the reciprocating and rotating 4-cylinder piston device of the first embodiment of the present invention, its cylinder 3 is composed of an outer cylindrical part 3A, a left / right annular ring combined with the two ends of the outer cylindrical part 3A Plates 3C, 3B are formed.

[0029] At both ends of the cylinder 3, in the circumferential direction of the central axis X, annular plates 2A, 2B with the same shape as the inner diameter of the annular plates 3C, 3B are respectively provided; inside the annular plates 2A, 2B, there are respectively formed The inner cylindrical portions 2C, 2D of the inner surface of the cylinder 3, which are integrally formed with the annular plates 2A, 2B, extend toward the inside of the cylinder, and on the outer peripheral surfaces of the respective inner cylindrical portions 2C, 2D, A pair of pistons 1A, 1B and 1C, 1D having a height and a width in the outer circumferential direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com