Electrical control system for assembling field bridge of rubber tyred gantry crane

An electrical control system, technology of gantry crane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

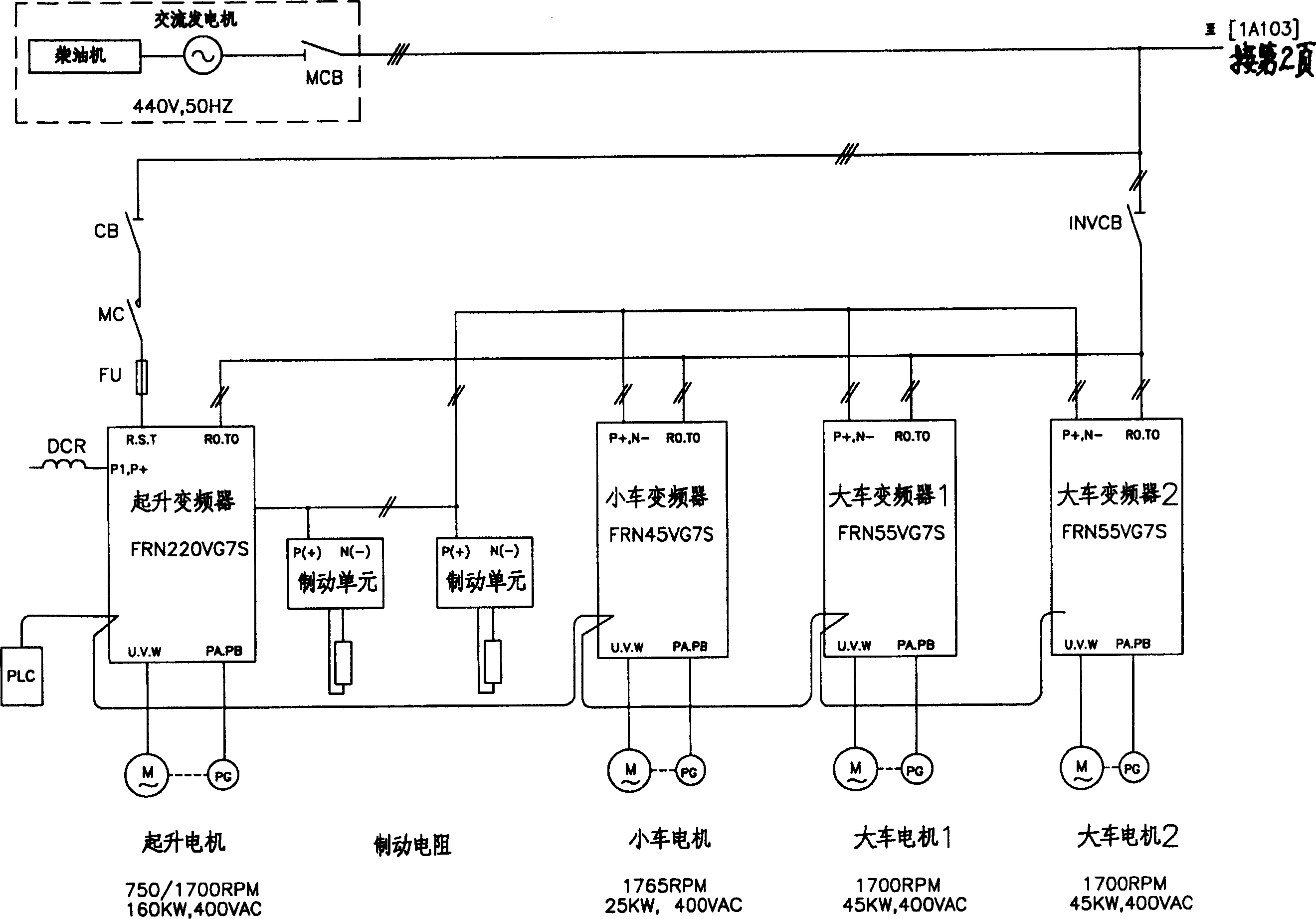

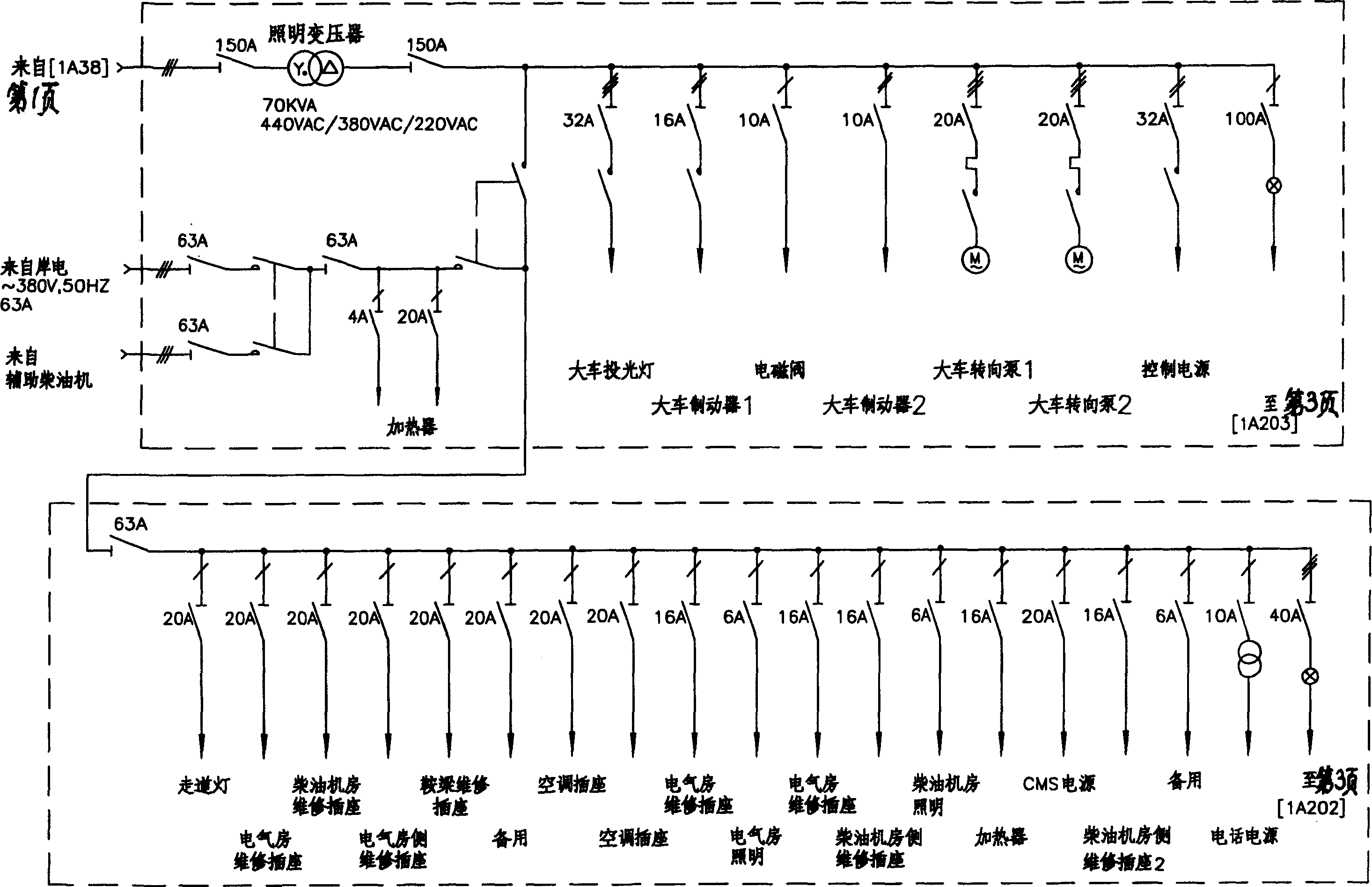

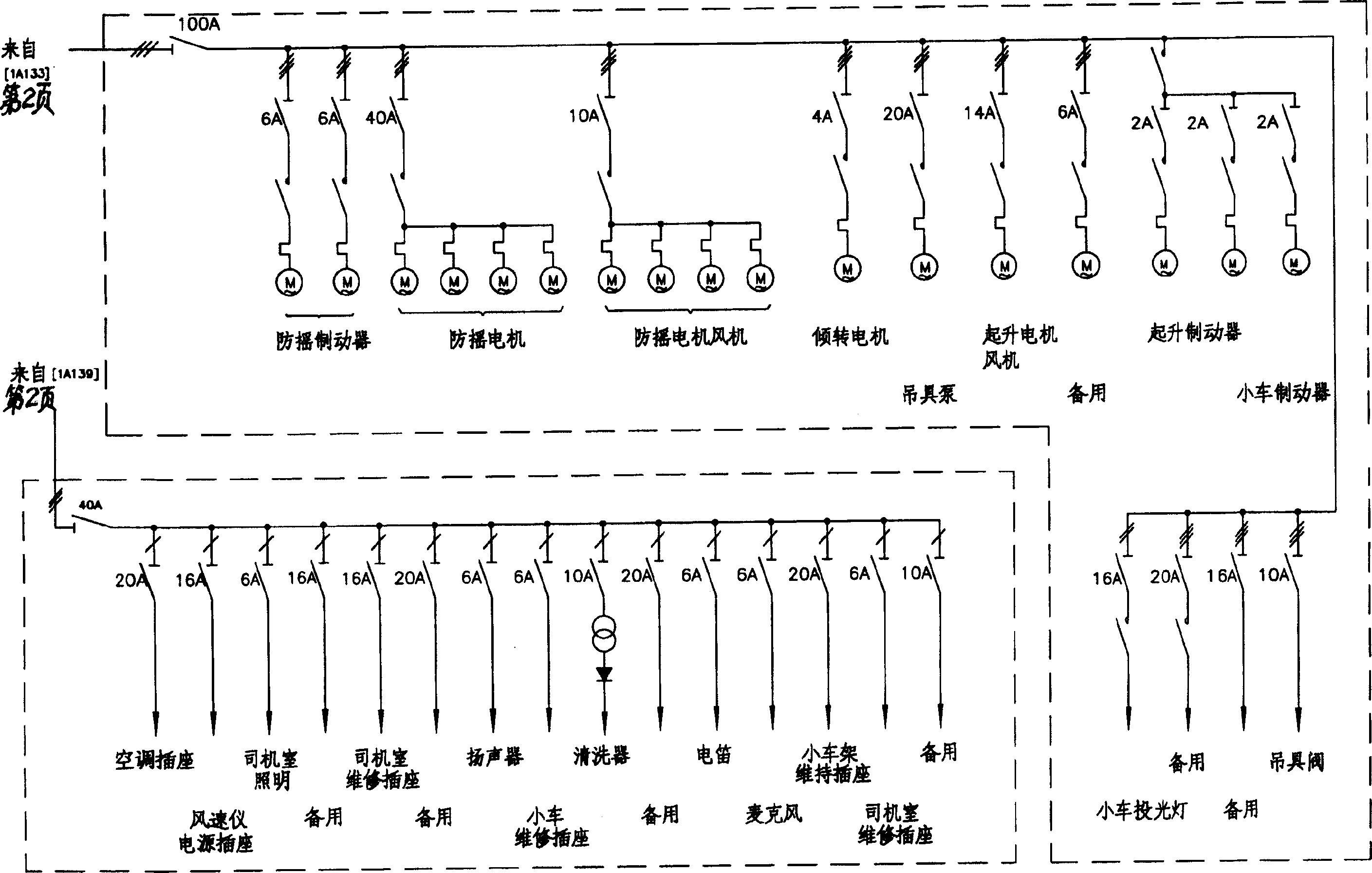

[0019] see Figure 1 to Figure 3 , The present invention is an electrical control system for assembly yard bridges of rubber-tyred gantry cranes, equipped with one or two hoisting frequency converters, one trolley frequency converter, and two or four cart frequency converters according to mechanical design requirements. According to the needs, the programmable logic controller PLC is equipped with a central processing unit CPU frame, several expansion frames and remote control modules.

[0020] This system includes an electrical control room or three to four electrical control panels placed in the electrical room, a small frame control panel and a driver's cab control panel or linkage platform. The hardware of this system is connected to each other through wiring.

[0021] Figure 1 to Figure 3 It shows the single line diagram, primary circuit diagram, control circuit diagram and corresponding auxiliary circuit diagram of the system.

[0022] The system adopts the control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com