Hydrolytic non-woven fabric and article employing the same for cleaning

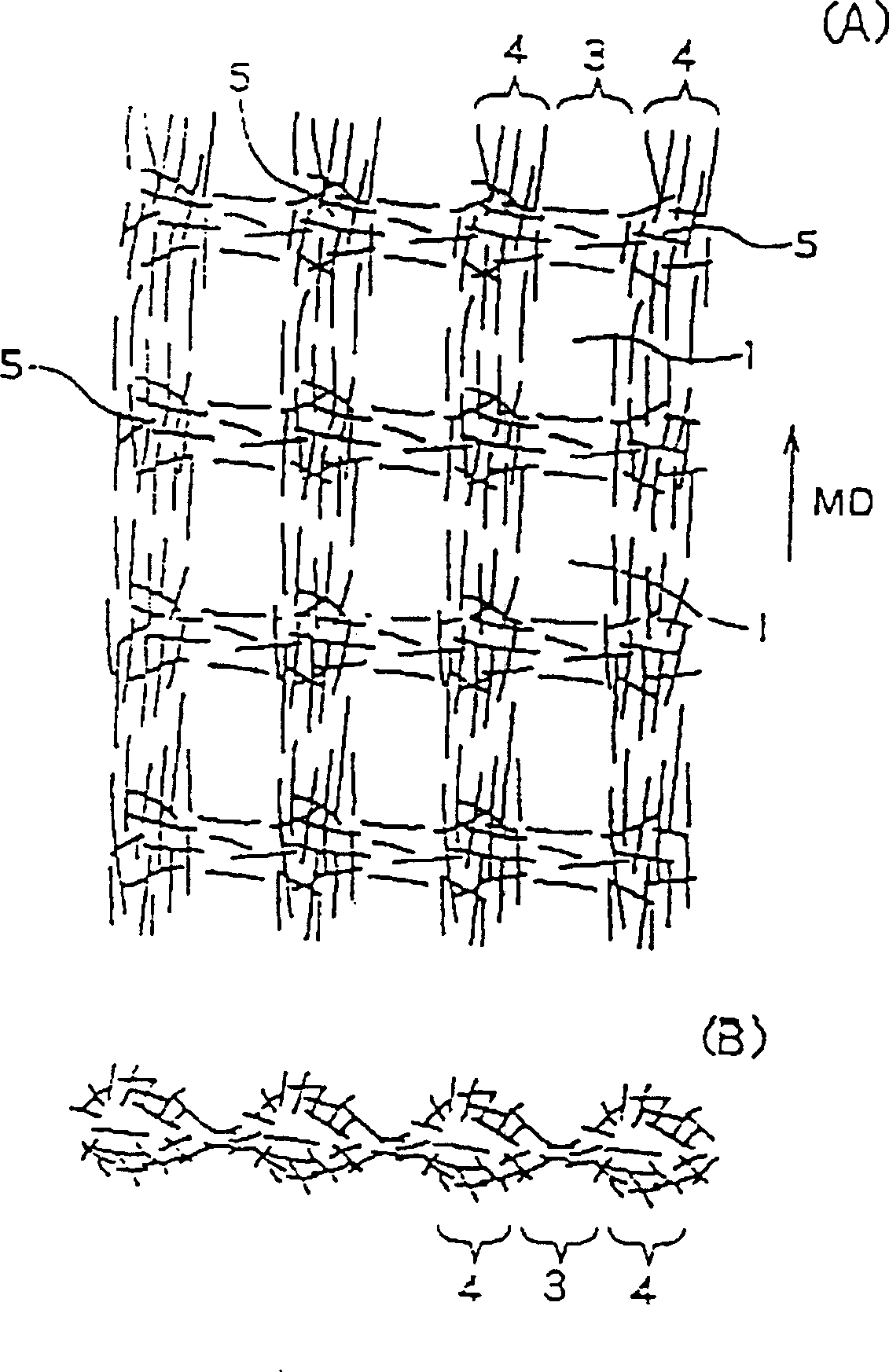

A technology of hydrolyzable non-woven fabrics, which is applied in the field of cleaning articles and hydrolyzable cleaning articles. It can solve the problems of bulky wet strength and hydrolyzability, and achieve excellent wiping effect and bulky volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0051] The test was carried out on the fiber sheet which is the main body of the water-disintegrable nonwoven fabric of the present invention and which does not include an adhesive.

[0052] As the raw material fiber, the fiber length shown in Table 1 is adopted, and the dimension is 1.5 denier man-made fiber (produced by Dongbang Ray——ョン (strain)), it is mixed according to the concentration of 0.2%, by laboratory mixing, by means of plastic filament Carry out papermaking operations so as to produce a size of 25cm x 25cm and a weight per unit area of 40g / m 2 fiber web. Without drying it, put it on the conveyor in the state where it is superimposed on the plastic filament, and spray water on it while conveying the fiber web at a speed of 30m / min Processing to wind up the fibers. In the high-pressure water jet injection device used at this time, the pitch of the nozzle holes with a diameter of 95 microns is 0.5mm, and there are 2000 nozzles / m side by side, and the nozzle hol...

Embodiment B

[0057] In the same manner as in Example A, a test was performed on the following fiber sheet, which mainly contained the water-disintegrable nonwoven fabric of the present invention and which did not contain an adhesive.

[0058] As raw material fiber, adopting fiber length is 7mm, and dimension is the rayon of 1.5denier (Tobang Ray——ョン (strain) production), according to the same manner as embodiment A, form the unit area weight that has table 2 to list A fiber web with a size of 25cm x 25cm. Thereafter, in the same manner as in Example A, a fiber sheet was obtained, and hydrolyzability and wet strength were measured.

[0059] As a comparative example, the weight per unit area is 15g / m 2 The fiber sheets were also tested for hydrolysis and wet strength.

[0060] Table 2 shows the results.

[0061] 1st comparative example

Embodiment C

[0063] In the same manner as in Example A, a test was performed on the following fiber sheet, which mainly contained the water-disintegrable nonwoven fabric of the present invention and which did not contain an adhesive.

[0064] As raw material fiber, adopting fiber length is 7mm, and dimension is 1.5denier man-made fiber (Tobang Ray——ョン (strain) production), according to the same mode as embodiment A, forming size is 5cm * 25cm, weight per unit area 40g / m 2 fiber web. Thereafter, in the same manner as in Example A, fiber sheets were obtained under the conditions of the water spray treatment listed in Table 3, and the obtained hydrolyzability and wet strength were measured.

[0065] As a comparative example, a test of hydrolyzability and wet strength was similarly performed on a fiber sheet not subjected to the water spray treatment.

[0066] Table 3 shows the results.

[0067] 1st comparative example

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com