Semiconductor device with fuse

A semiconductor and fuse technology, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., and can solve the problems of substrate damage and reduction of fuse breakage processing margins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

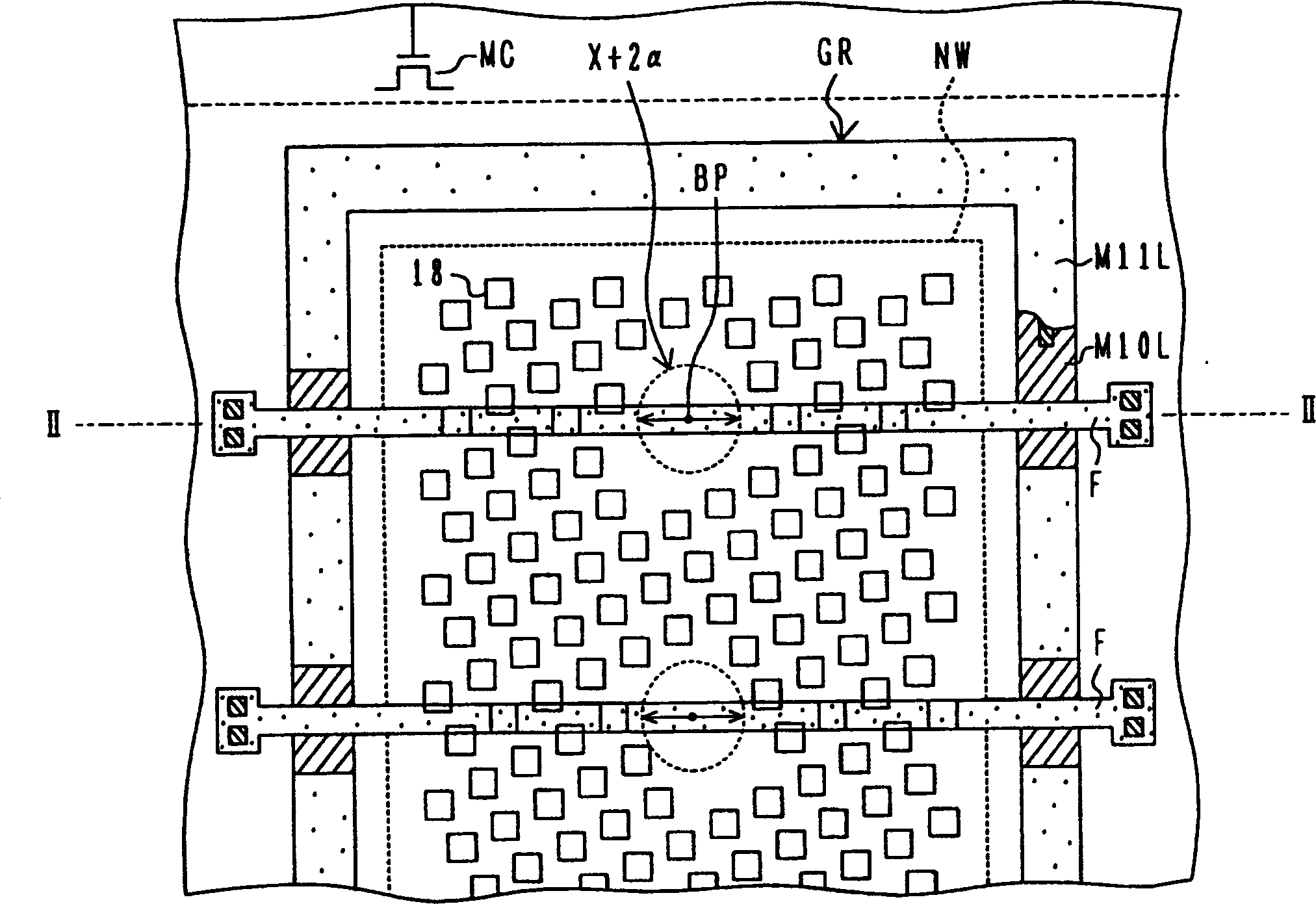

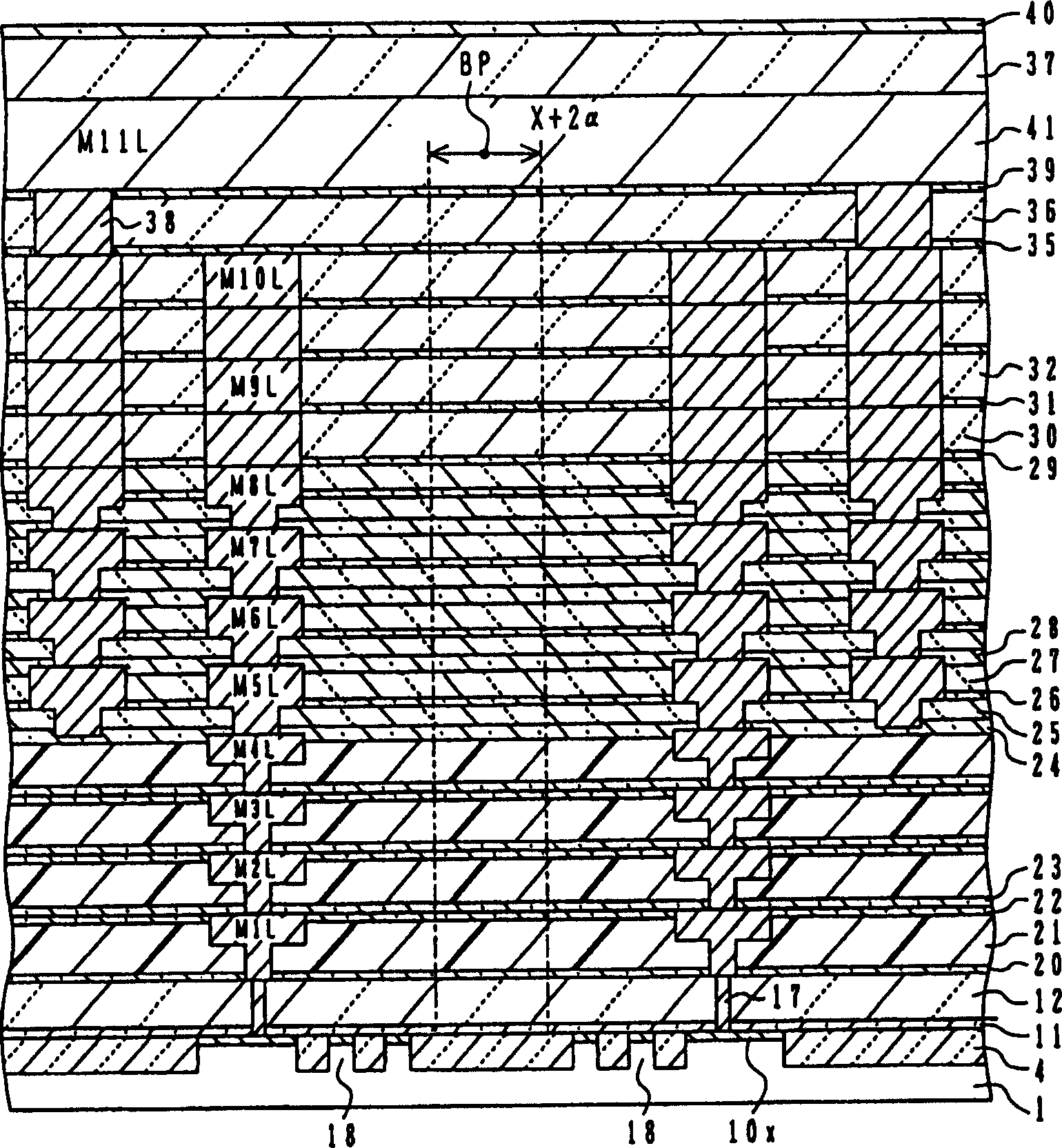

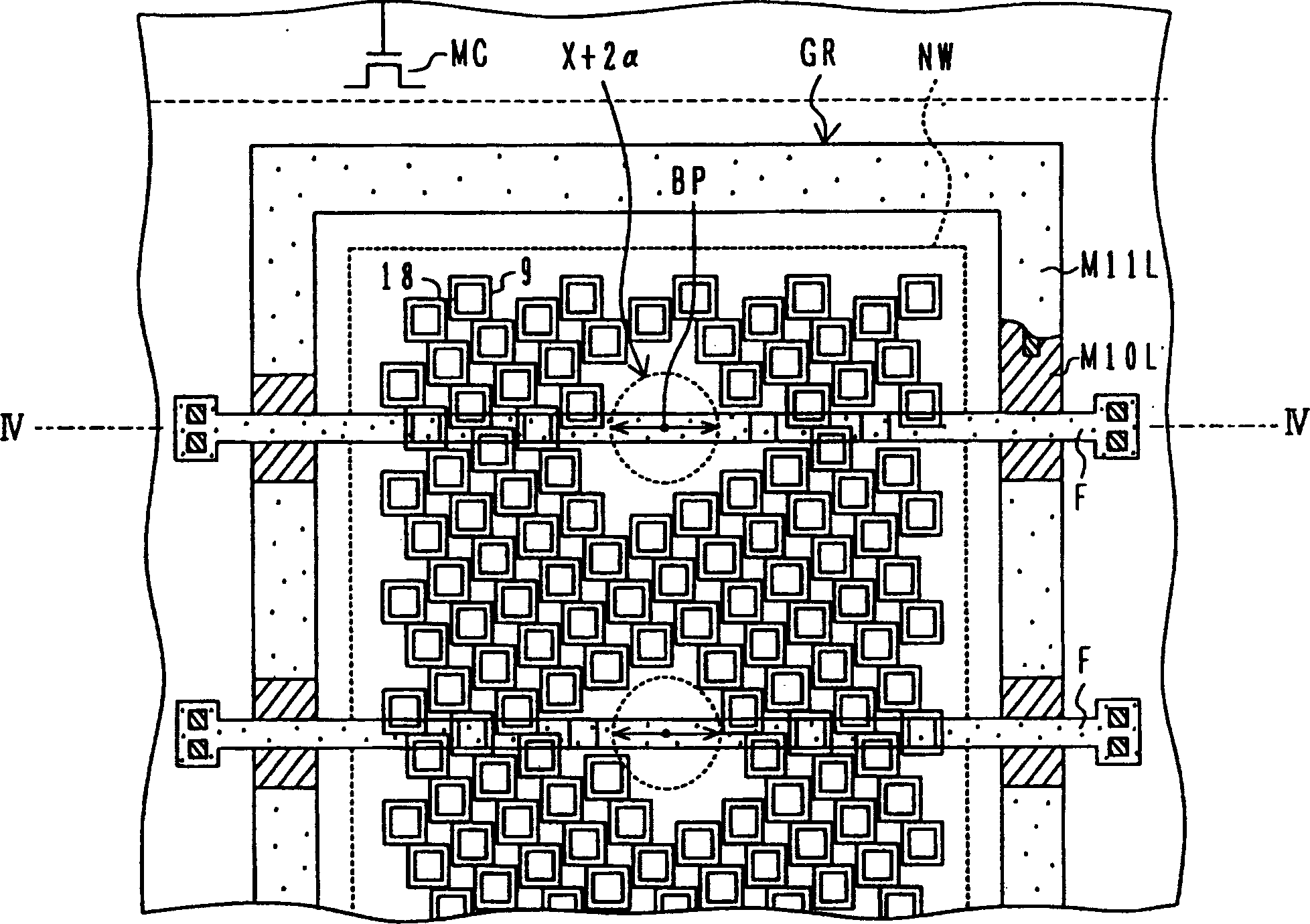

[0032] First, new facts discovered by the present inventors during development will be described. First, an example of a process for forming a dummy structure region will be described.

[0033] like Figure 9A As shown, on the surface of a silicon substrate 1, a silicon oxide film 2 having a thickness of about 10 nm is grown by oxidation with hydrochloric acid at 900°C. On this silicon oxide film 2, a silicon nitride film 3 is grown to a thickness of about 110 nm by chemical vapor deposition (CVD).

[0034] A photoresist pattern is formed on silicon nitride film 3, and silicon nitride film 3 and silicon oxide film 2 are etched by anisotropic etching. The photoresist pattern is then removed. By using silicon nitride film 3 as a mask, silicon substrate 1 is anisotropically etched. For example, an approximately 300 nm thick surface layer of the silicon substrate is etched away to form trenches approximately 300 nm deep.

[0035] like Figure 9B As shown, a silicon oxide fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com