Paper sheet input method and device

An input method and paper technology, applied in the directions of transportation and packaging, object separation, object supply, etc., can solve the problems of high precision of cam curve processing, high noise of cam linkage mechanism, and reduced printing quality of bills, etc., to achieve simple structure , improved equipment accuracy and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

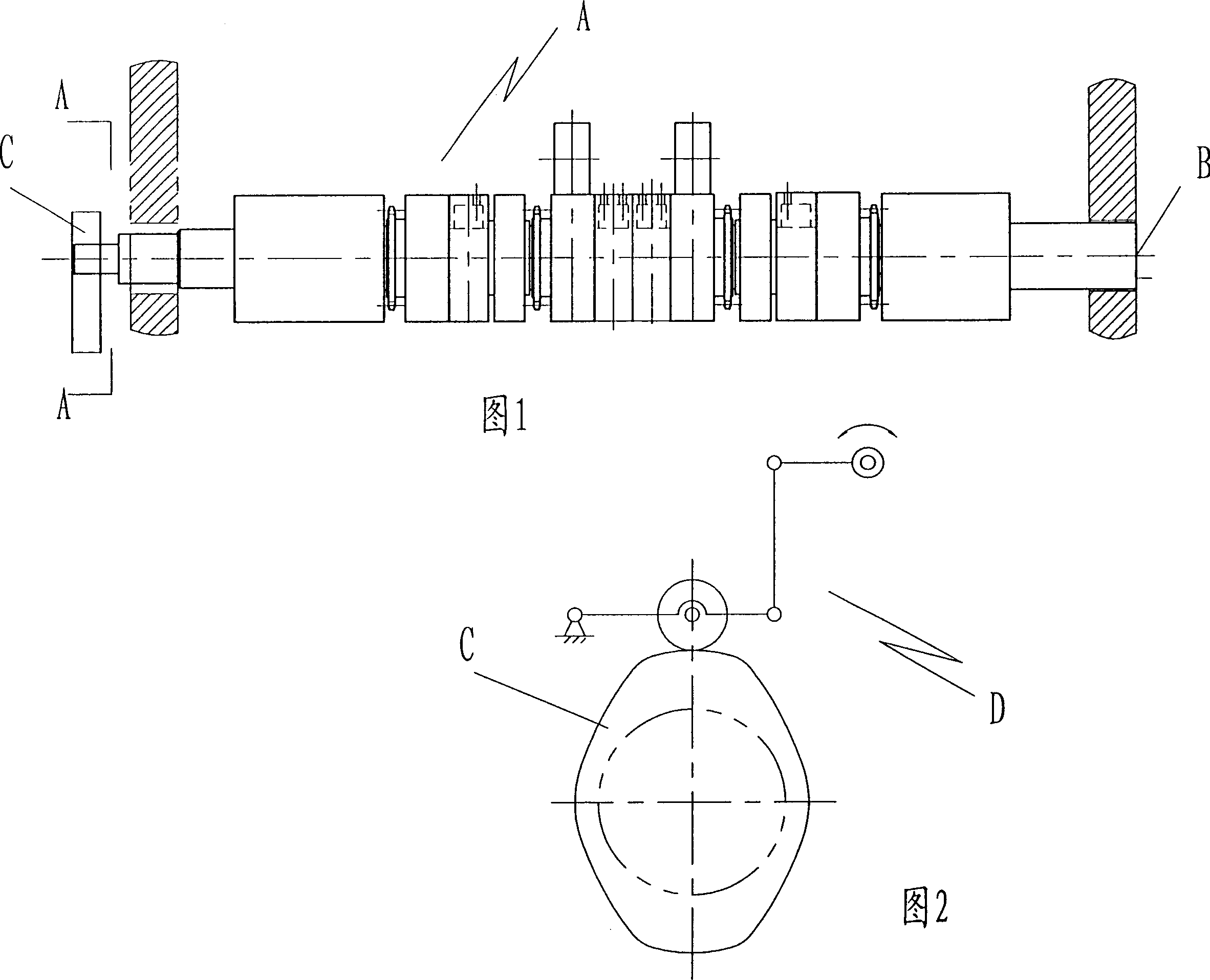

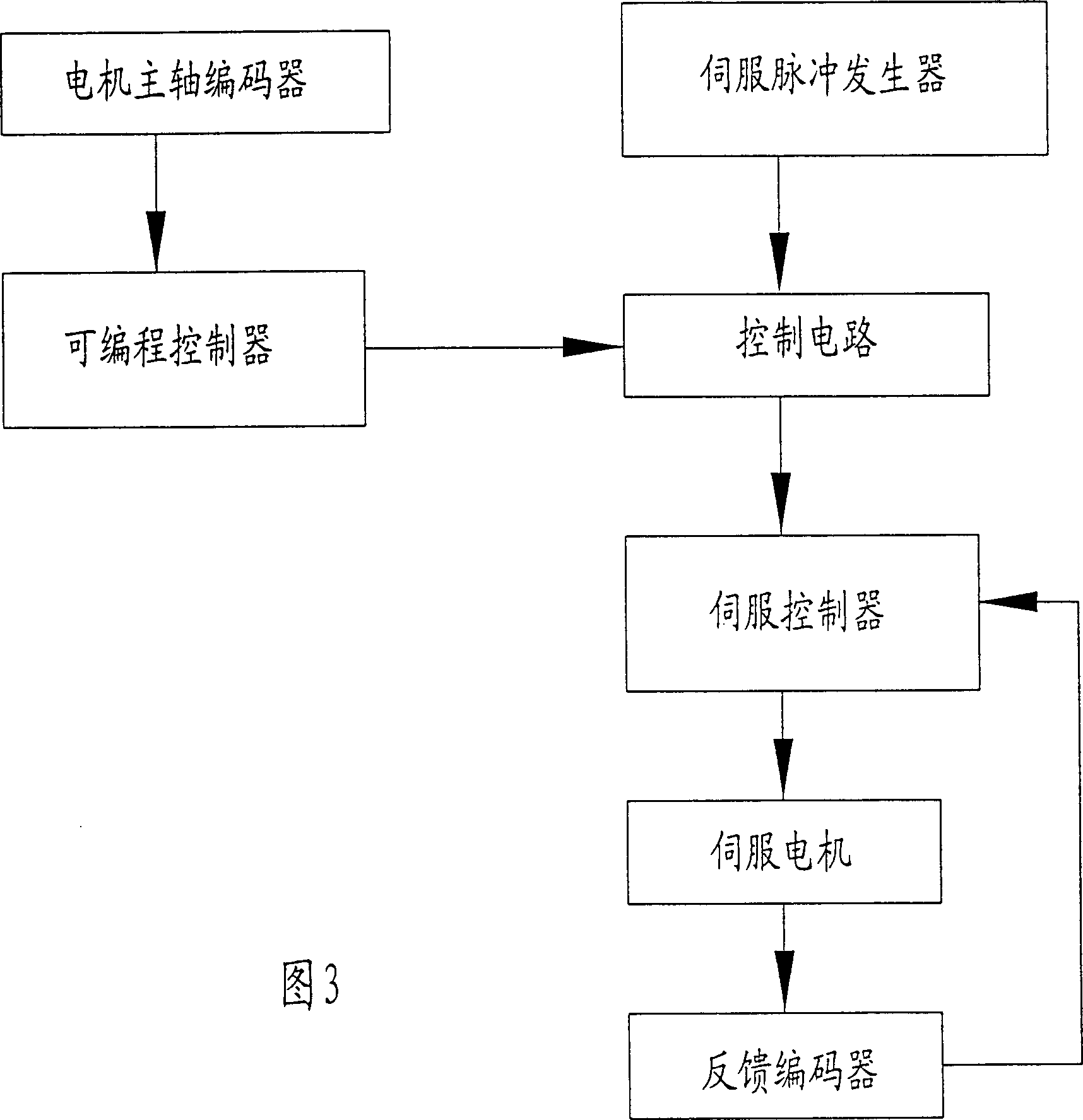

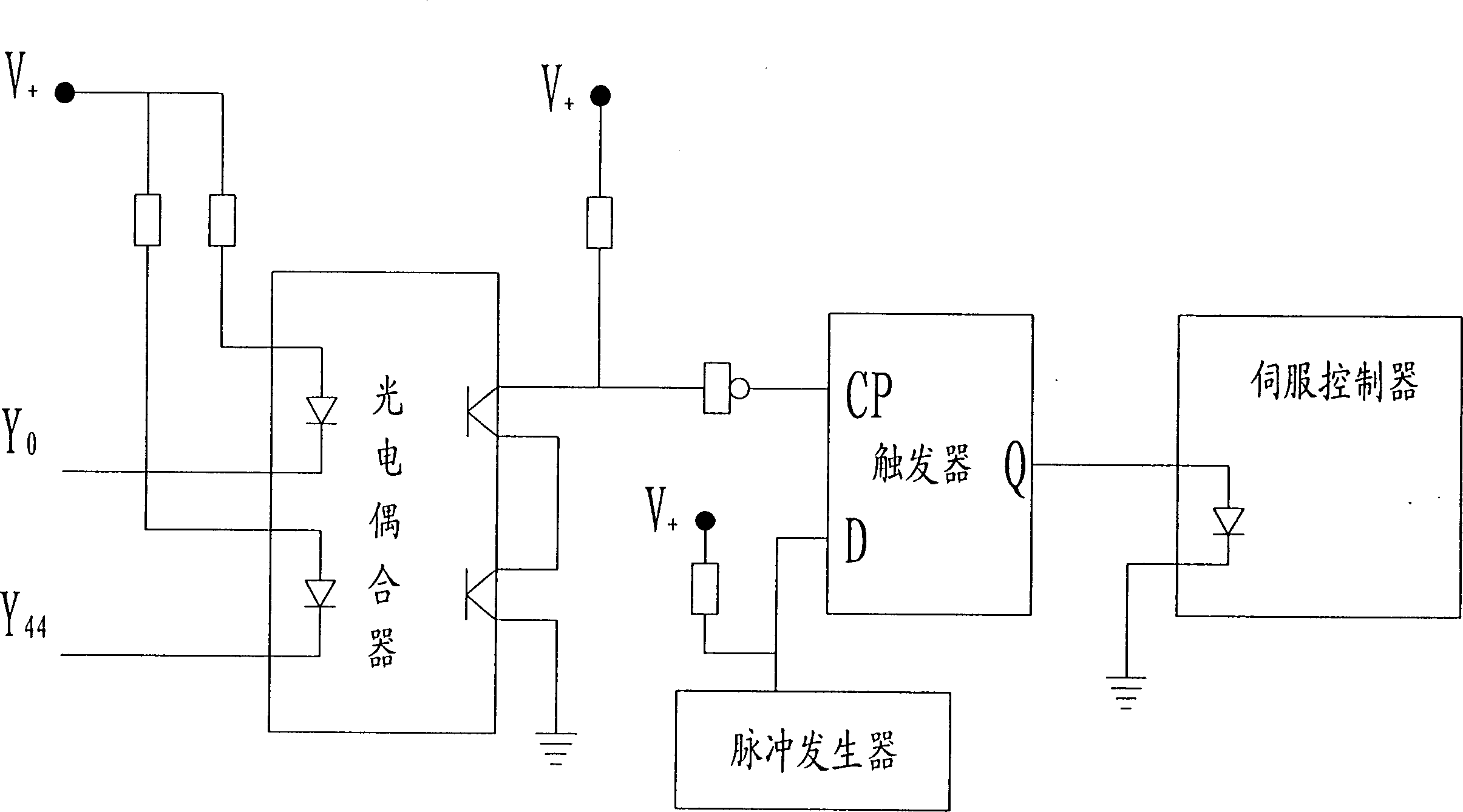

[0047] In order to have a further understanding of the technical features, purpose and effect of the paper input method and device of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings.

[0048] Such as Figure 7 , 8 As shown, the paper input method of the present invention includes: setting the paper stack 3 on the paper stack guide rail 4, connecting the paper feeder 1 arranged at the front end of the main machine to the air source, and driving the flyer 1 by the servo motor under the control of the electric control device. Feeder 1 starts to rotate, and absorbs the paper 30 from zero speed to the main machine speed, and transports the paper to the main machine drive line 5 at a position perpendicular to the production line, completes the handover, and disconnects the air source at the same time, and the feeder continues to rotate back to the initial position, so The upper part of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com