Method for manufacturing imbedded non-volatile memory with sacrificed layer

A manufacturing method and gate dielectric layer technology, which can be used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as inability to effectively shorten transistor channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

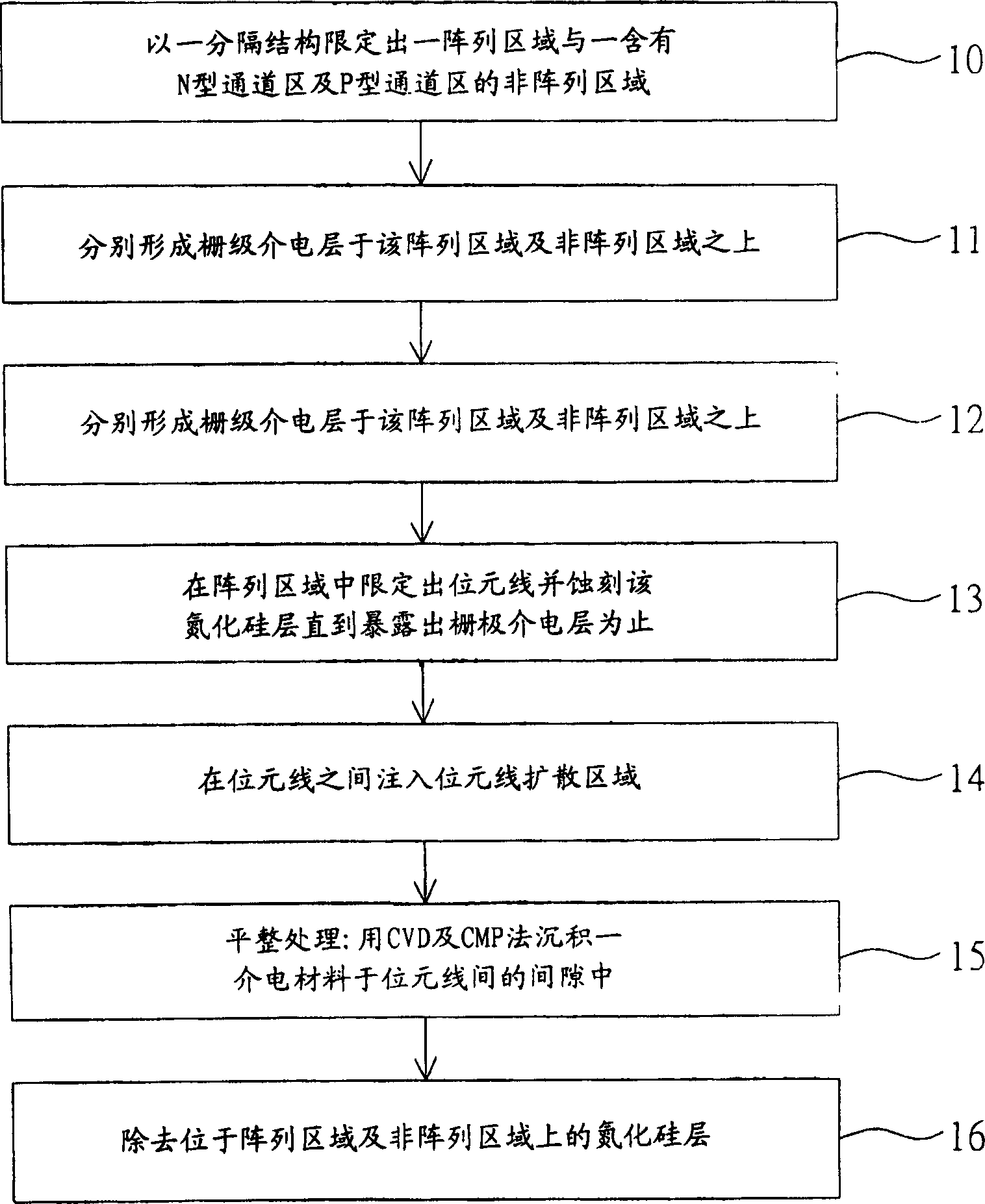

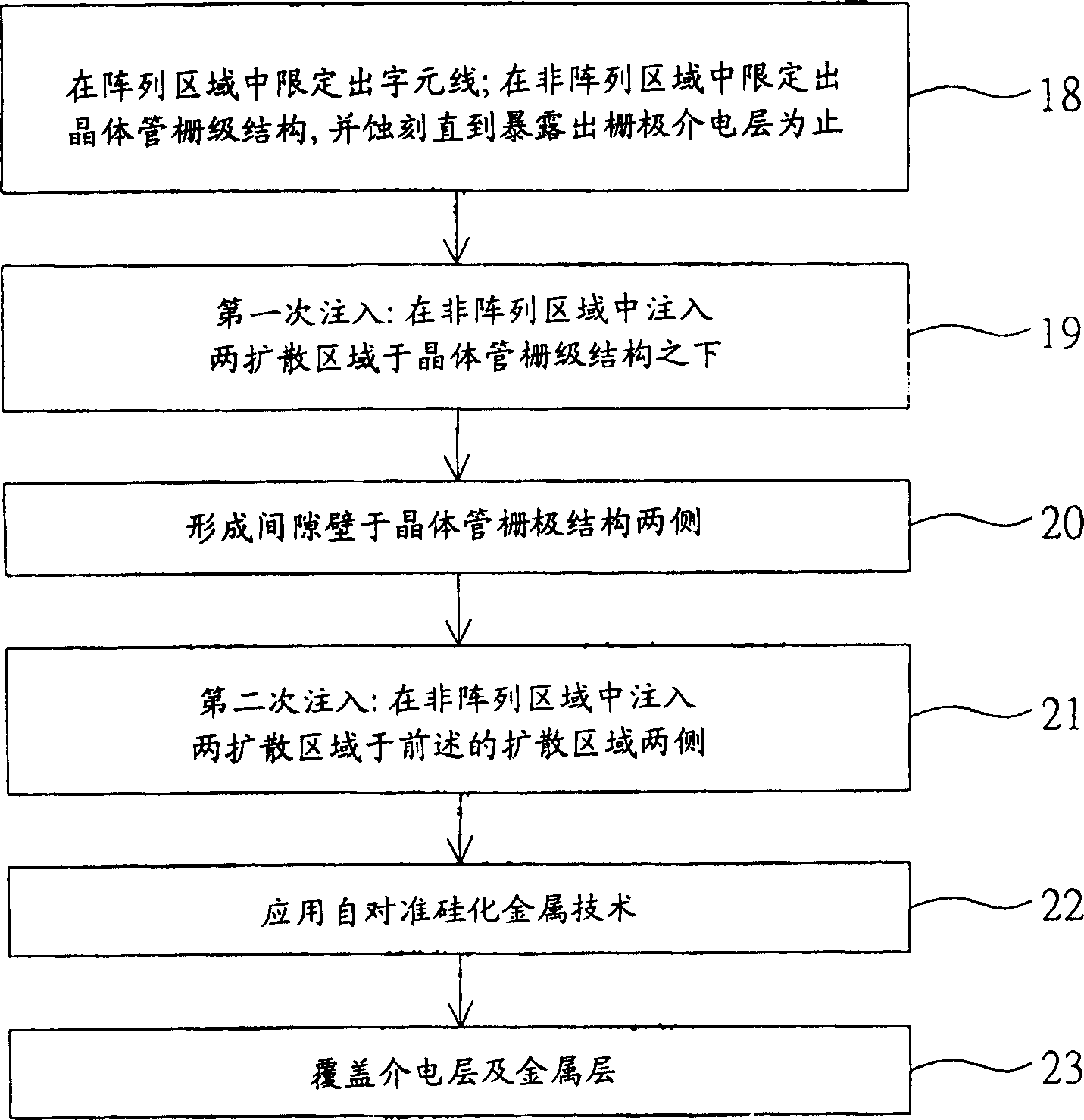

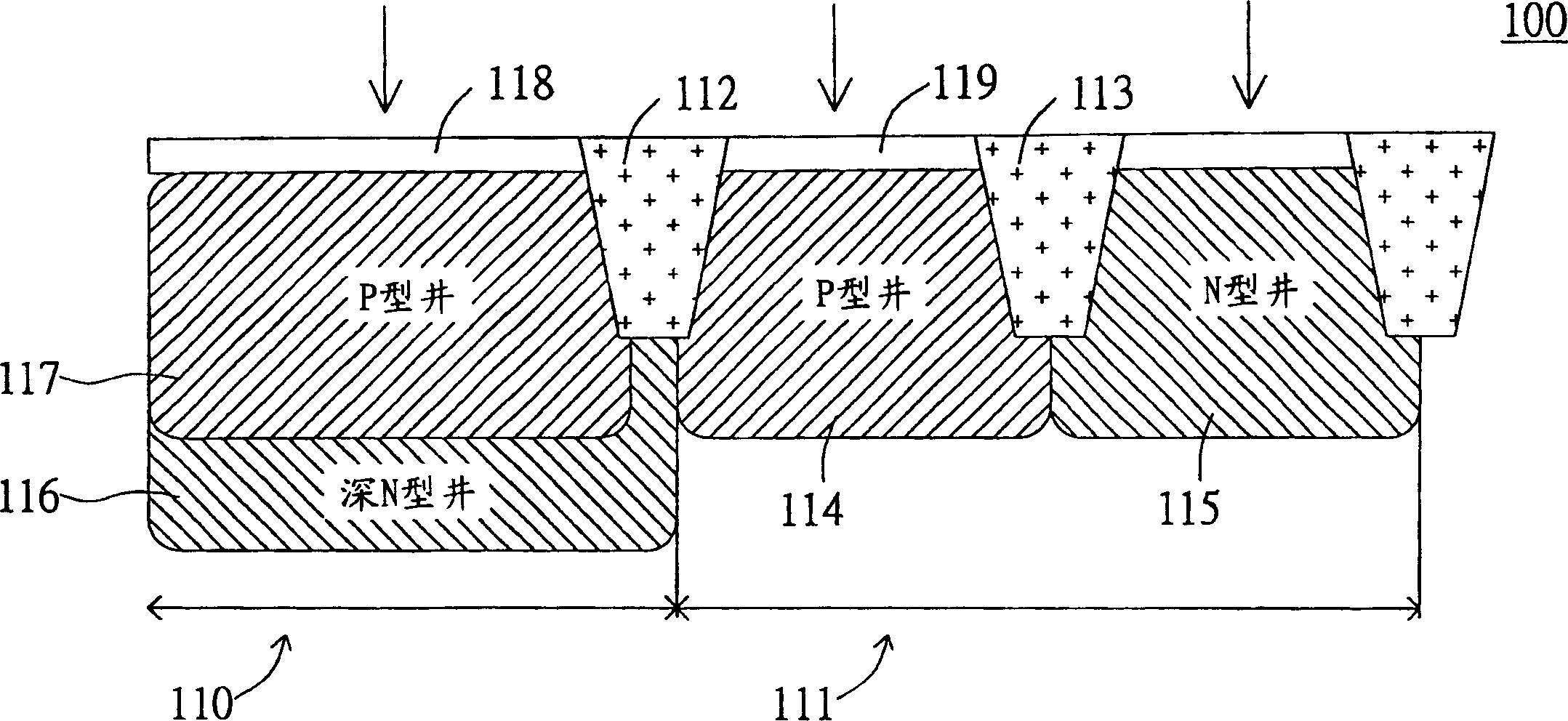

[0057] The detailed manufacturing method and practical application disclosed in the present invention will be described as follows with reference to the accompanying drawings. Figure 1A ~ Figure 1B It is a flowchart of a manufacturing method drawn according to an embodiment of the present invention. Figure 2 to Figure 10 Illustrated structure diagram of Figure 1A ~ Figure 1B related steps. and Figure 11 It is a sectional view of an embedded non-volatile memory structure with a SONOS memory unit drawn by applying the present invention.

[0058] Please refer to Figure 1A ~ Figure 1B , each step will be described in numerical order from step block 10 to step block 23 to illustrate the manufacturing method of the present invention. First, as described in step block 10 , an array area 110 and a non-array area 111 are defined on the substrate 100 by separating the substrate 100 with a dielectric region 112 . As shown in FIG. 2, the dielectric region 112 is formed on the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com