Ozone/hydrogen peroxide advanced film oxide reactors

A technology of hydrogen peroxide and advanced oxidation, which is applied in the direction of oxidized water/sewage treatment, etc., and can solve the problems of low reaction efficiency and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

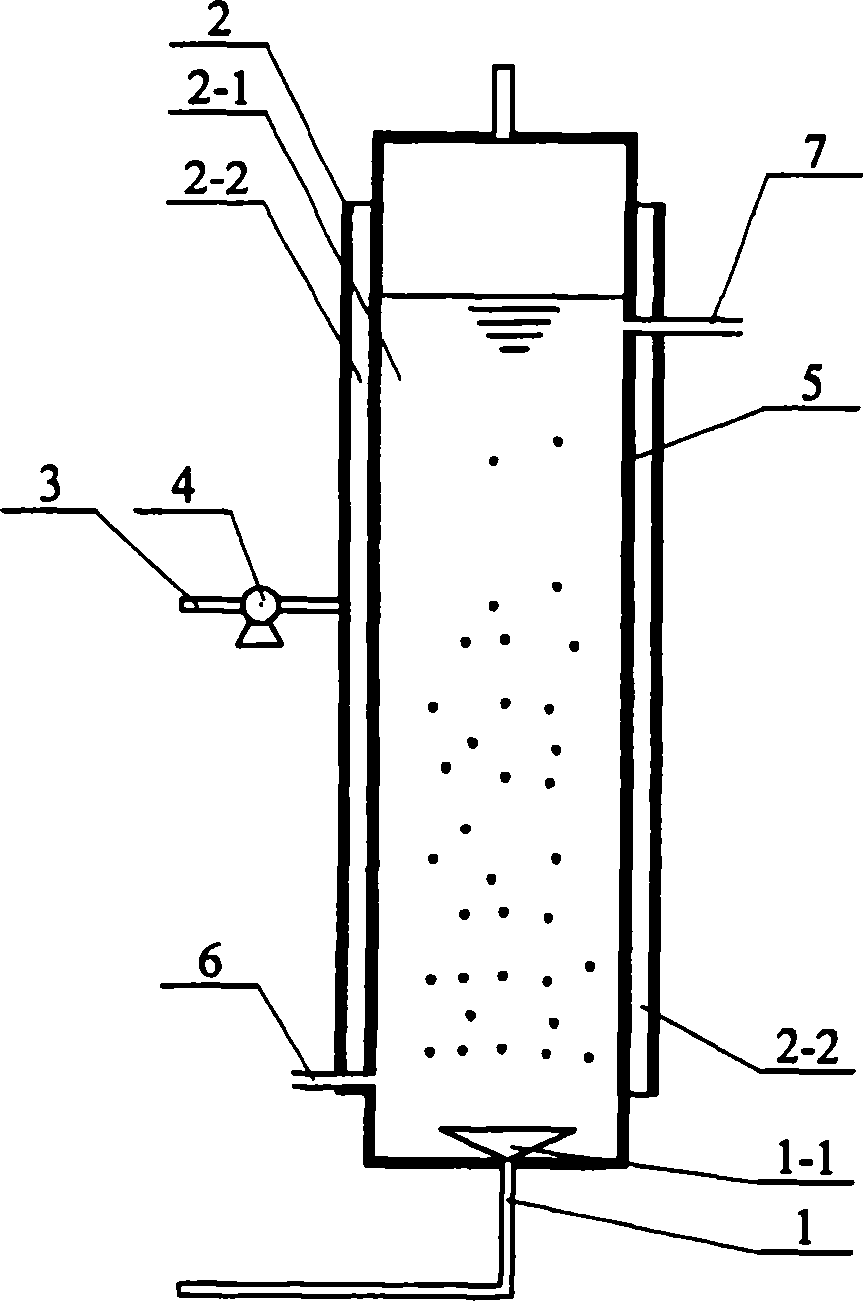

specific Embodiment approach 1

[0005] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment is composed of ozone exposure pipe 1, reaction vessel 2, water inlet pipe 6, water outlet pipe 7, catalyst inlet pipe 3, membrane body 5 and booster pump 4, and the membrane body 5 that can be permeated by hydrogen peroxide molecules will react The space in the container 2 is separated into a reaction chamber 2-1 and a hydrogen peroxide chamber 2-2, the inner end of the ozone exposure pipe 1 is connected to the bottom in the reaction chamber 2-1, and the inner side of the water inlet pipe 6 and the water outlet pipe 7 The ends communicate with the reaction chamber 2-1 respectively, the booster pump 4 is arranged in the catalyst inlet pipe 3, and the inner end of the catalyst inlet pipe 3 is connected to the hydrogen oxide chamber 2-2. An aeration head 1-1 is arranged on the inner end of the ozone exposure pipe 1 . The water inlet pipe 6 ...

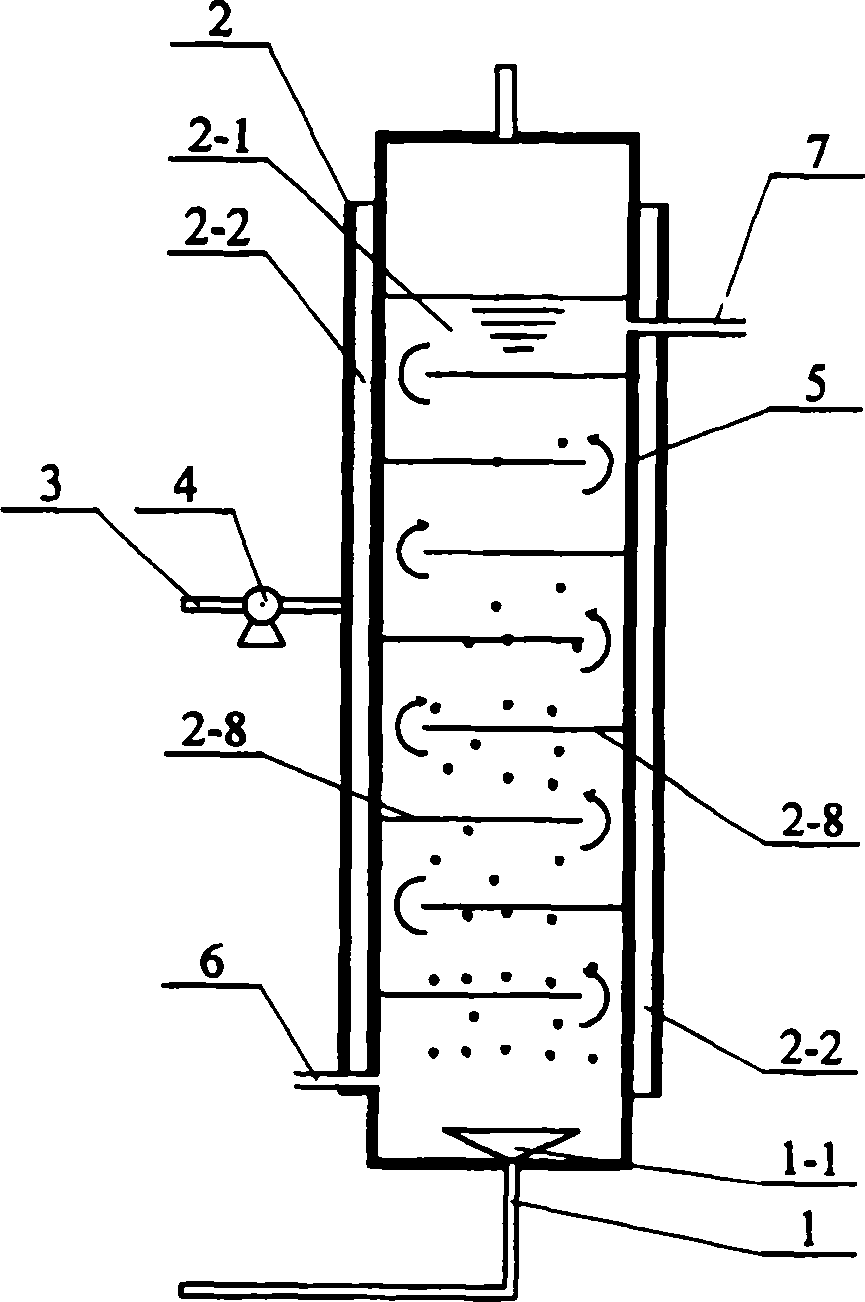

specific Embodiment approach 2

[0006] Specific implementation mode two: the following combination figure 2 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that several baffles 2-8 are fixed on the inner wall surface of the reaction chamber 2-1 from top to bottom, and the several baffles 2-8 are arranged staggeredly from top to bottom. On the surface of the inner wall of the reaction chamber 2-1, adjacent baffles 2-8 are respectively fixed on opposite surfaces of the inner wall of the reaction chamber 2-1. Such setting makes the water body zigzagging upwards to form turbulent flow, so that ozone and hydrogen peroxide can mix and contact more fully.

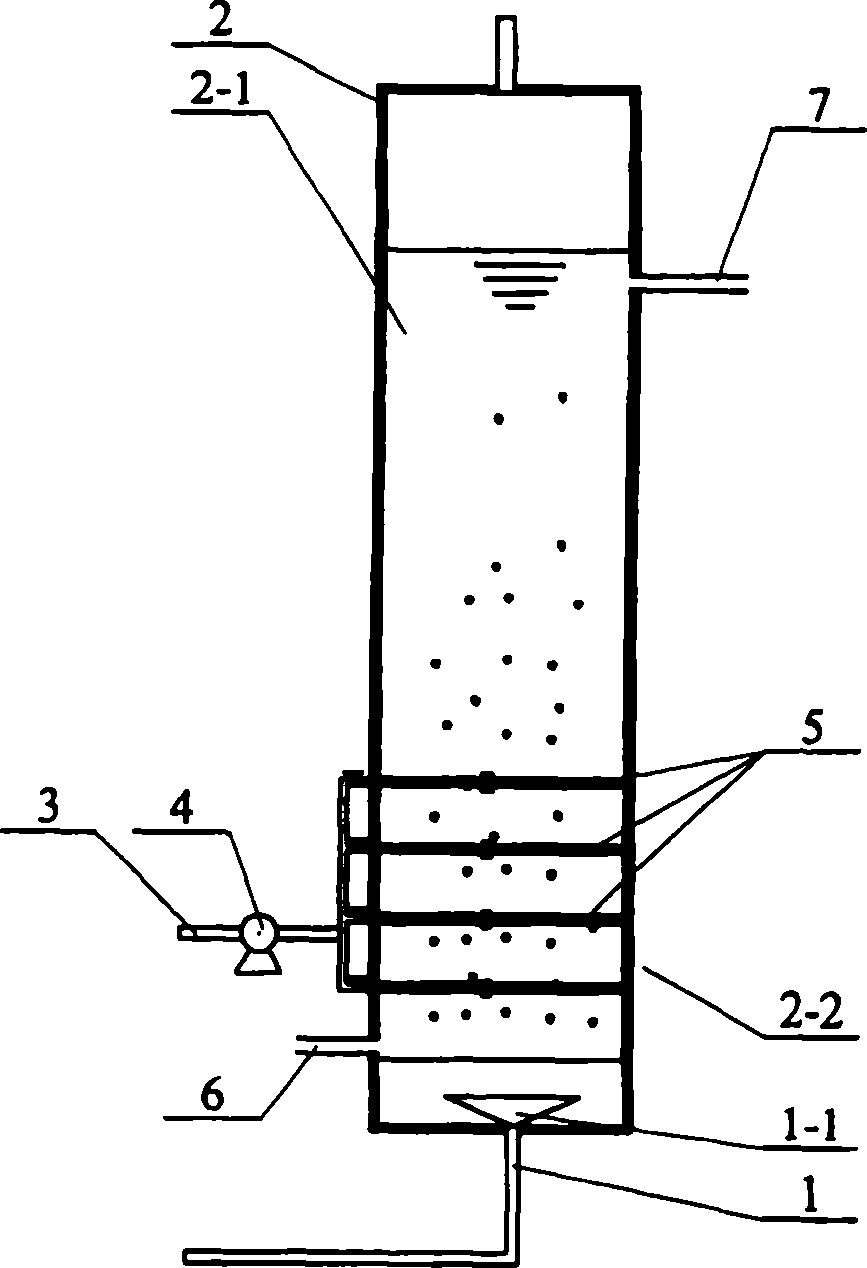

specific Embodiment approach 3

[0007] Specific implementation mode three: the following combination image 3 and Figure 4 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that the membrane body 5 uses several tubular membranes or several groups of hollow fiber modules, and all the tubular membranes or hollow fiber modules are horizontally arranged in the reaction vessel 2, and the tubular membranes or One end of the hollow fiber module is connected to the catalyst inlet pipe 3, and the other end of the tubular membrane or hollow fiber module is closed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap