Prepn process of nano copper iodide powder

A copper iodide, nanotechnology, applied in the field of preparation of nano-scale copper iodide powder directly by chemical reaction method, can solve the problems of no preparation method and process report, etc., and achieve easy industrial scale production and simple process Easy to control, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Prepare nano copper iodide powder according to the following process steps.

[0018] a. Prepare the following two solutions separately:

[0019] Copper sulfate clarified aqueous solution, the solution contains: copper sulfate 0.1M / L, citric acid (complexing agent) 0.068M / L;

[0020] Potassium iodide clear aqueous solution, the solution contains: potassium iodide 0.2M / L, citric acid (complexing agent) 0.136M / L, sodium dodecyl sulfonate (dispersant) 0.02M / L;

[0021] b. Slowly add the above-prepared clarified copper sulfate aqueous solution dropwise to the clarified potassium iodide aqueous solution under normal temperature and normal pressure while fully stirring, and obtain nano-copper iodide precipitation after standing and settling;

[0022] c. The above-mentioned nano-copper iodide precipitate is filtered, washed three times with water, and dried at a temperature of 80-100° C. for 1 to 2.5 hours to obtain nano-copper iodide powder with a particle size of 30-60 nm.

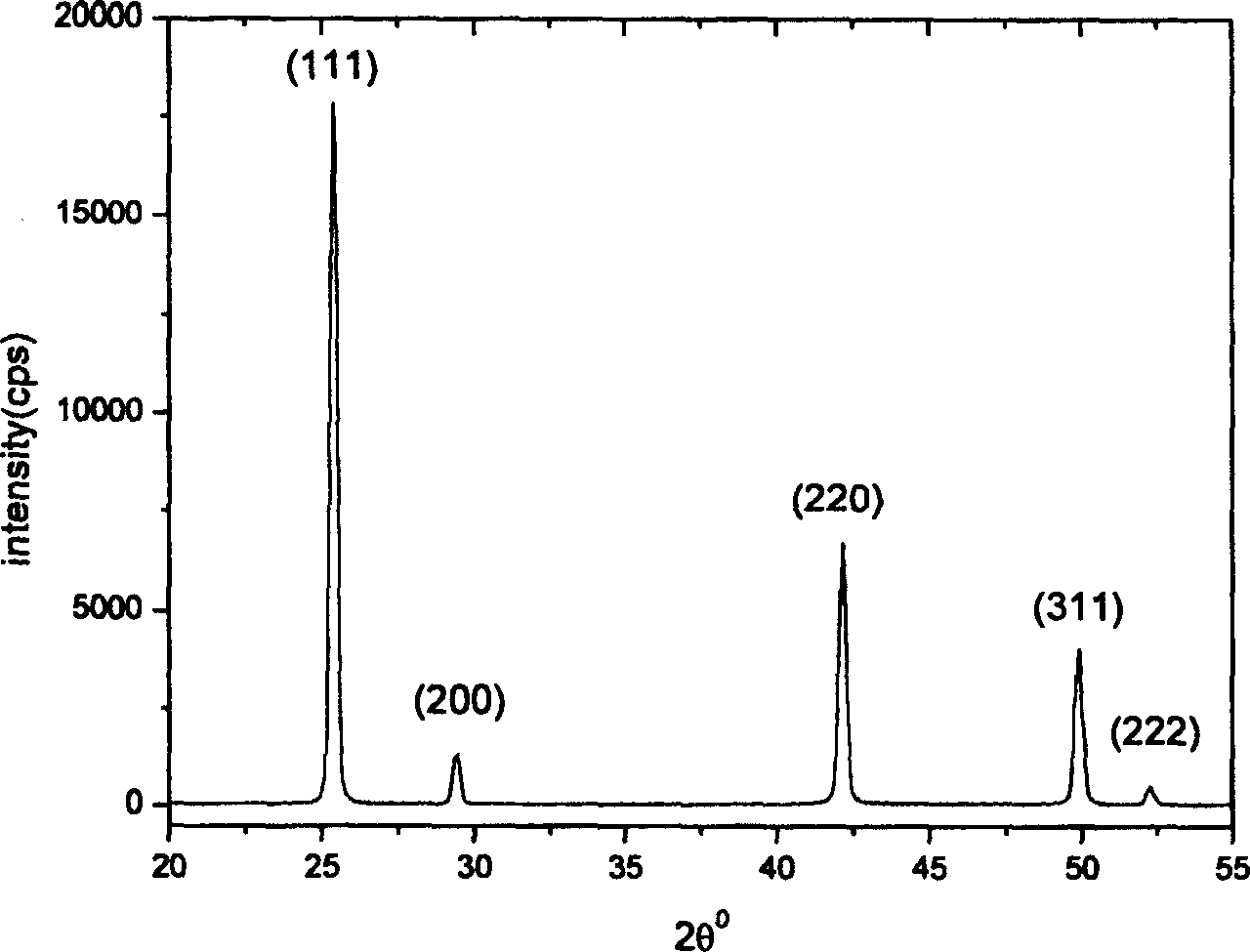

[002...

Embodiment 2

[0032] Prepare nano copper iodide powder according to the following process steps.

[0033] a. Prepare the following two solutions separately:

[0034] Copper sulfate clarified aqueous solution, the solution contains: copper sulfate 0.2M / L, citric acid (complexing agent) 0.136M / L;

[0035] Potassium iodide clarified aqueous solution, the solution contains: potassium iodide 0.4M / L, citric acid (complexing agent) 0.136M / L, sodium lauryl sulfonate (dispersant) 0.04M / L;

[0036] b. Slowly add the above-prepared clarified copper sulfate aqueous solution dropwise to the clarified potassium iodide aqueous solution under normal temperature and normal pressure while fully stirring, and obtain nano-copper iodide precipitation after standing and settling;

[0037] c. The above-mentioned nano-copper iodide precipitate is filtered, washed three times with water, and dried at a temperature of 80-100° C. for 1 to 2.5 hours to obtain nano-copper iodide powder with a particle size of 70-100 nm.

Embodiment 3

[0039] Prepare nano copper iodide powder according to the following process steps.

[0040] a. Prepare the following two solutions separately:

[0041] Copper sulfate clarified aqueous solution, the solution contains: copper sulfate 0.15M / L, citric acid (complexing agent) 0.102M / L;

[0042] Potassium iodide clarified aqueous solution, the solution contains: potassium iodide 0.3M / L, citric acid (complexing agent) 0.102M / L, sodium lauryl sulfonate (dispersant) 0.03M / L;

[0043] b. Slowly add the above-prepared clarified copper sulfate aqueous solution dropwise to the clarified potassium iodide aqueous solution under normal temperature and normal pressure while fully stirring, and obtain nano-copper iodide precipitation after standing and settling;

[0044] c. The above-mentioned nano-copper iodide precipitate is filtered, washed with water three times, and dried at a temperature of 80-100° C. for 1 to 2.5 hours to obtain nano-copper iodide powder with a particle size of 45-75 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com