New type polyolefin thermoplastic elastomer

A thermoplastic elastomer and polyolefin technology, which is applied in the field of polyolefin thermoplastic elastomers, can solve the problems of odor generation, expensive POE, environmental impact, etc., and achieve low cost, excellent mechanical properties and processing performance, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

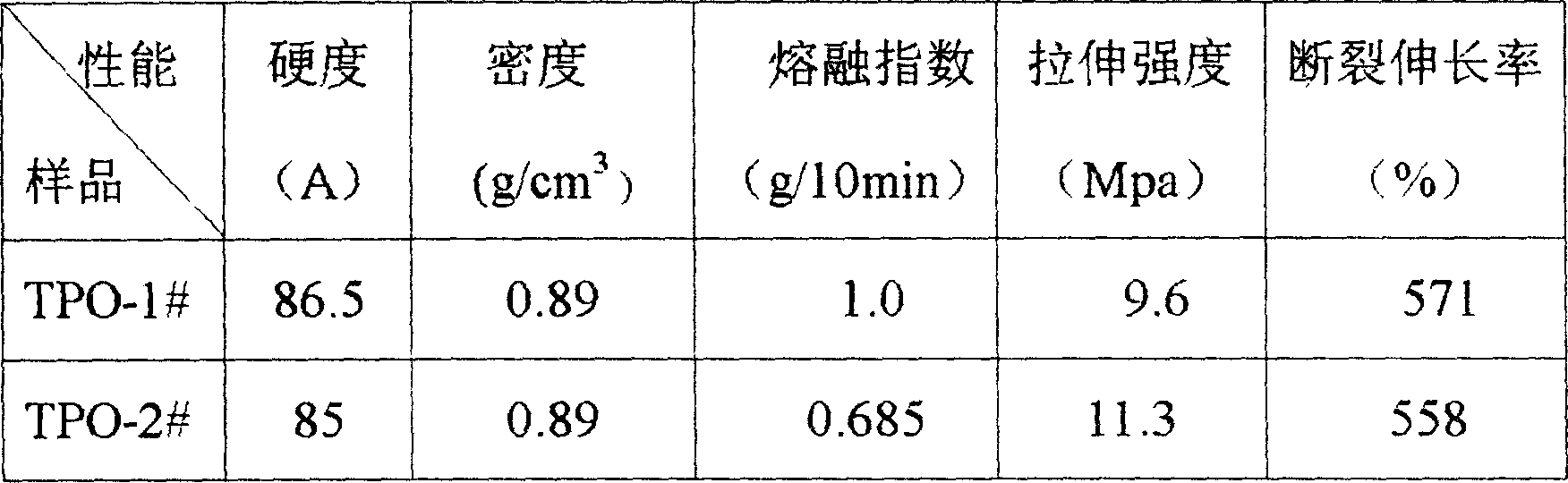

Image

Examples

Embodiment 1

[0025] Embodiment one weight percent (%)

[0026] PPZ30S 29.3

[0027] POE8180 58.5

[0028] SBS(791) 9.8

[0029] Vulcanizing agent 101 0.15

[0030] Auxiliary cross-linking agent TAIC 0.15

[0031] Nano Talc 1.9

[0032] Antioxidant 1010 0.1

[0033] Light stabilizer 770 0.1

[0034] Tensile strength

[0035] The test condition of melt index is 190°C / 2.16Kg, the same below.

Embodiment 2

[0036] Embodiment two weight percent (%)

[0037] PPZ30S 29.3

[0038] POE8180 63.5

[0039] SBS(791) 4.8

[0040] Vulcanizing agent 101 0.15

[0041] Auxiliary cross-linking agent TAIC 0.15

[0042] Nano Talc 1.9

[0043] Antioxidant 1010 0.1

[0044] Light stabilizer 770 0.1

[0045] Tensile strength

degree MPa

elongation at break

Rate(%)

Melt Index

(g / 10min)

Stress at modulus

A

D

100%

200%

300%

9.7

577

0.7

88

26

5.6

6.5

7.4

[0046] Implement three weight percentage (%)

[0047] PPZ30S 29.3

[0048] POE8180 48.5

[0049] SBS(791) 19.8

[0050] Vulcanizing agent 101 0.15

[0051] Auxiliary cross-linking agent TAIC 0.15

[0052] Nano Talc 1.9

[0053] Anti-slip agent 1010 0.1

[0054]Light stabilizer 770 0.1

[0055] Tensile strength

Embodiment 4

[0056] Embodiment four weight percent (%)

[0057] PPZ30S 39.3

[0058] POE8180 28.5

[0059] SBS(791) 29.8

[0060] Vulcanizing agent 101 0.15

[0061] Auxiliary cross-linking agent TAIC 0.15

[0062] Nano Talc 1.9

[0063] Antioxidant 1010 0.1

[0064] Light stabilizer 770 0.1

[0065] Tensile strength

[0066] The ratio of each raw material can be adjusted according to the user's requirements, and TPO products with various specifications can be produced with performance that meets the needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com