Loudspeaker vibrating diaphragm base material structure and manufacturing method thereof

A manufacturing method and membrane substrate technology, applied in the direction of diaphragm structure, sensors, electrical components, etc., can solve problems such as insufficient sound quality, influence of output tone of paper vibrating membrane, cracking, etc., to increase the effect of crisp metal audio transmission, Improves the effect of better recovery and improved fabric stretch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The purpose of the present invention and its structural and functional characteristics will be described below in conjunction with the accompanying drawings and preferred embodiments.

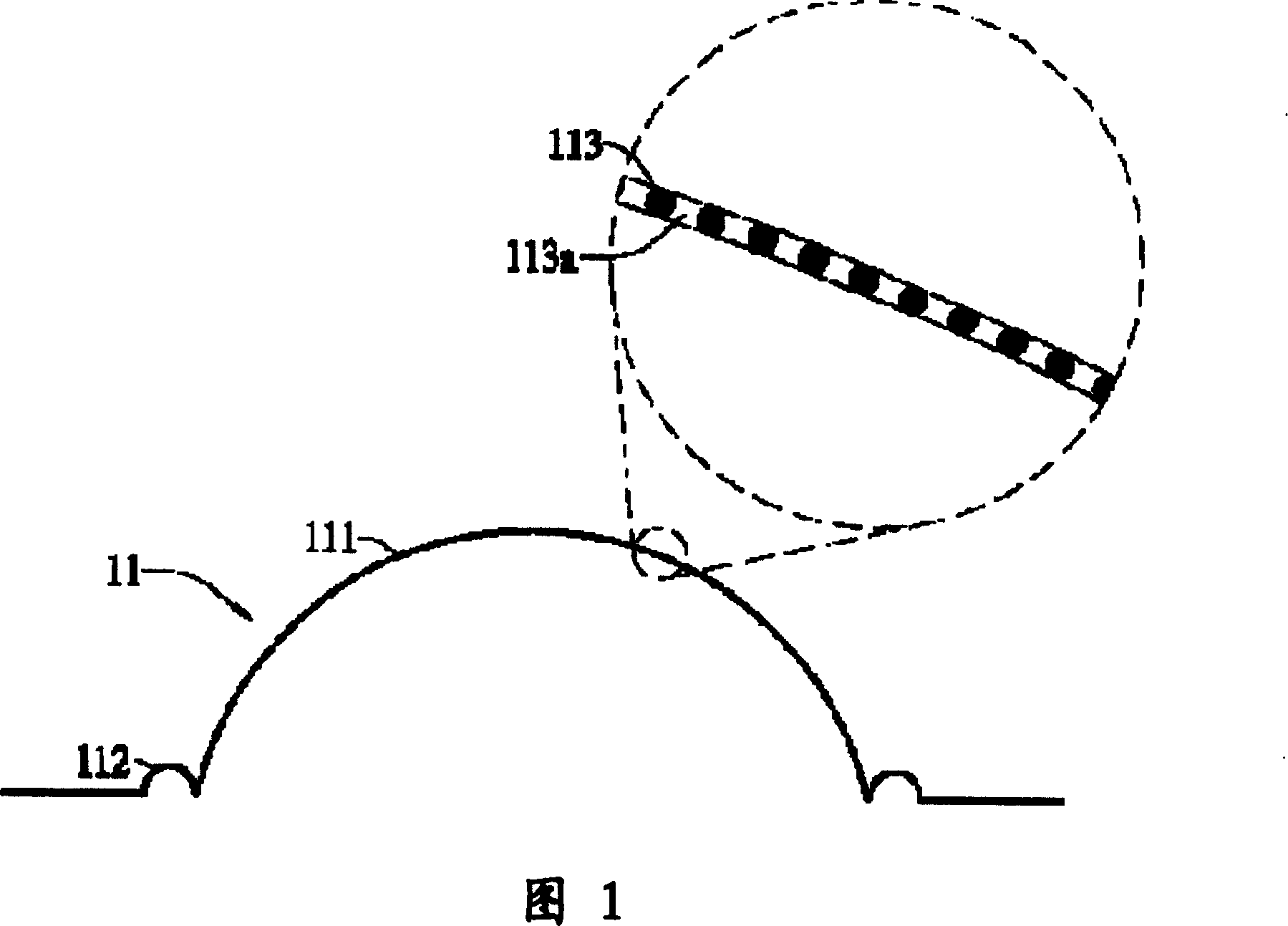

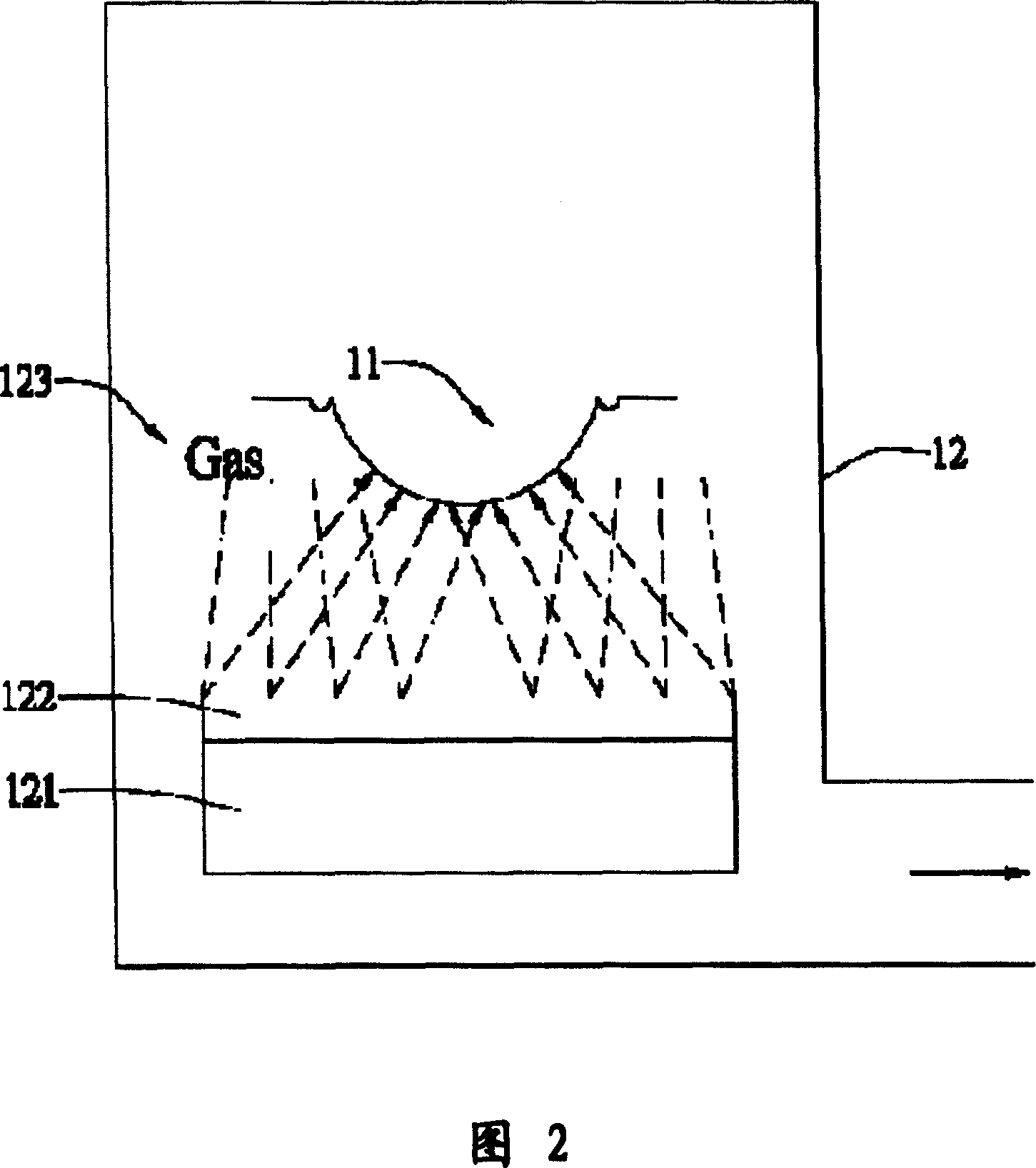

[0017] Please refer to the first embodiment of the present invention shown in Fig. 1, Fig. 2 and Fig. 3, wherein the structural composition of the vibrating film base material 11 includes two parts of the vibrating film 111 and the edge portion 112, and the material of the vibrating film base material 11 It is selected from one of cloth, paper, and plastic materials, and the microstructure of these materials is composed of fiber structures 113 and holes 113a (see the partial enlarged view of FIG. 1 ).

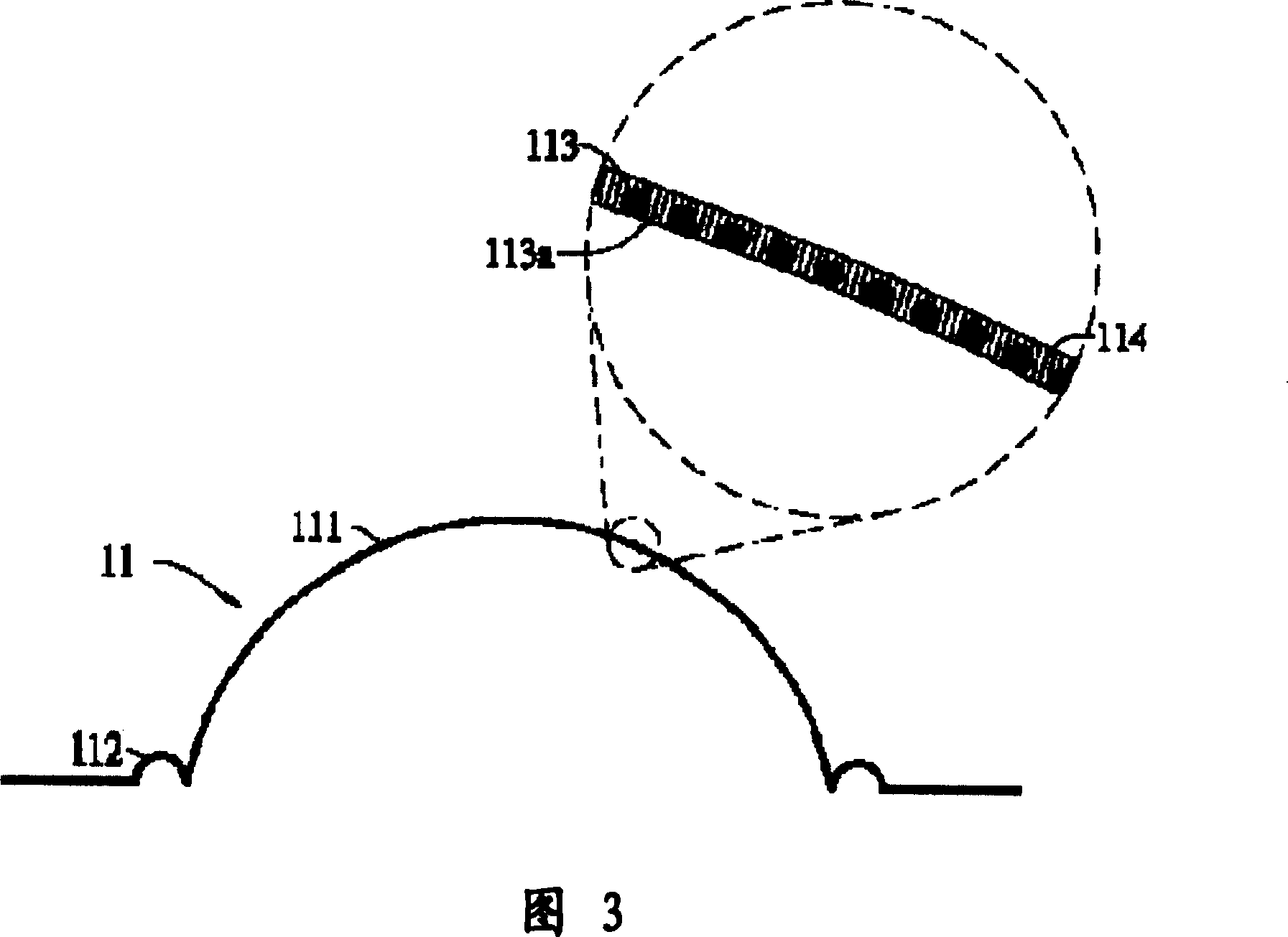

[0018] Referring to Fig. 2, wherein the flux tube 121 can be energized to generate a magnetic field, and the metal target 122 can be selected from titanium (Ti), aluminum (Al), chromium (Cr), nickel (Ni), copper (Cu), iron ( Fe), indium (In), zirconium (Zr), silver (Ag), gold (Au), german...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com