Method of producing hydrophilic polymer

A technology for the polymerization of hydrophilic polymers and monomers, used in the manufacture of hydrophilic polymers and the manufacture of vinyl-based hydrophilic polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] (manufacture of polymer coagulant)

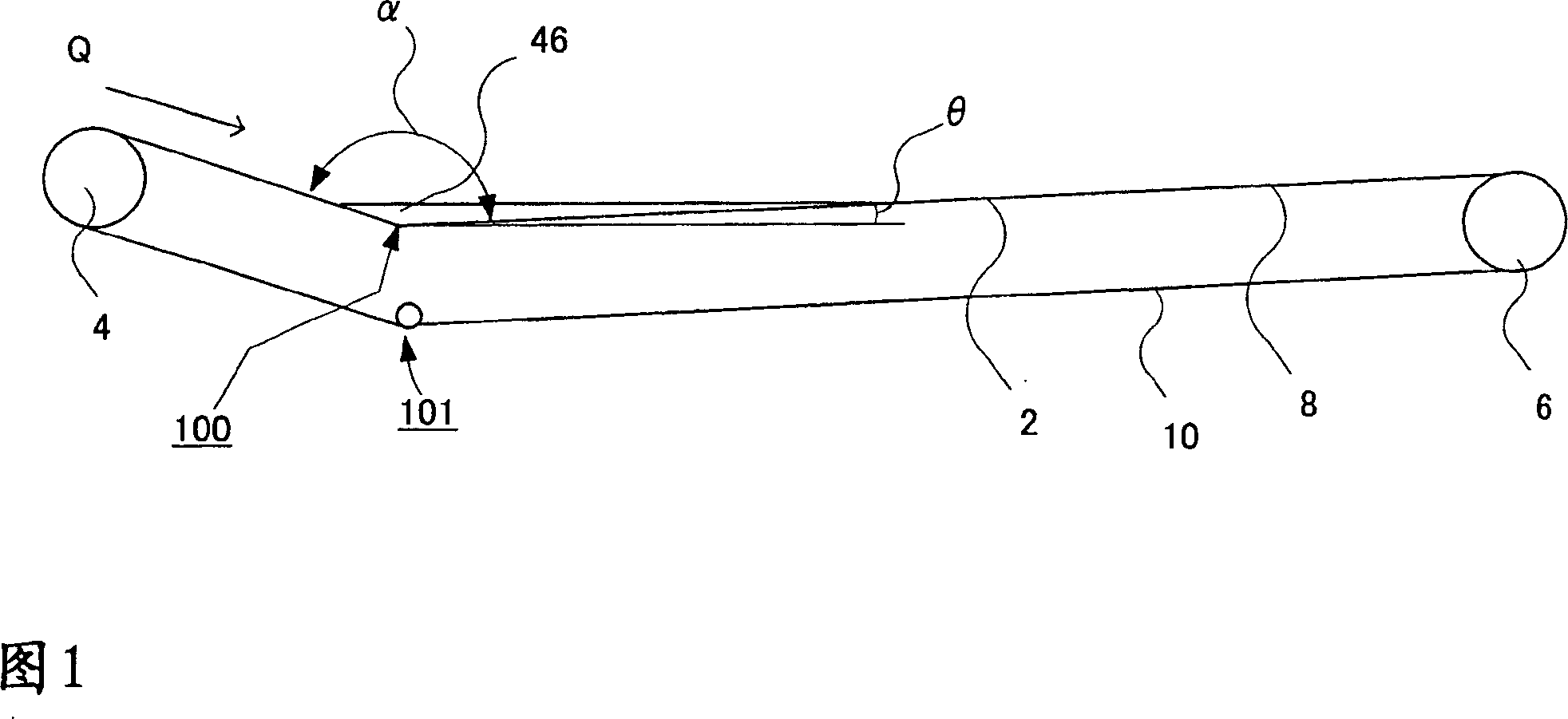

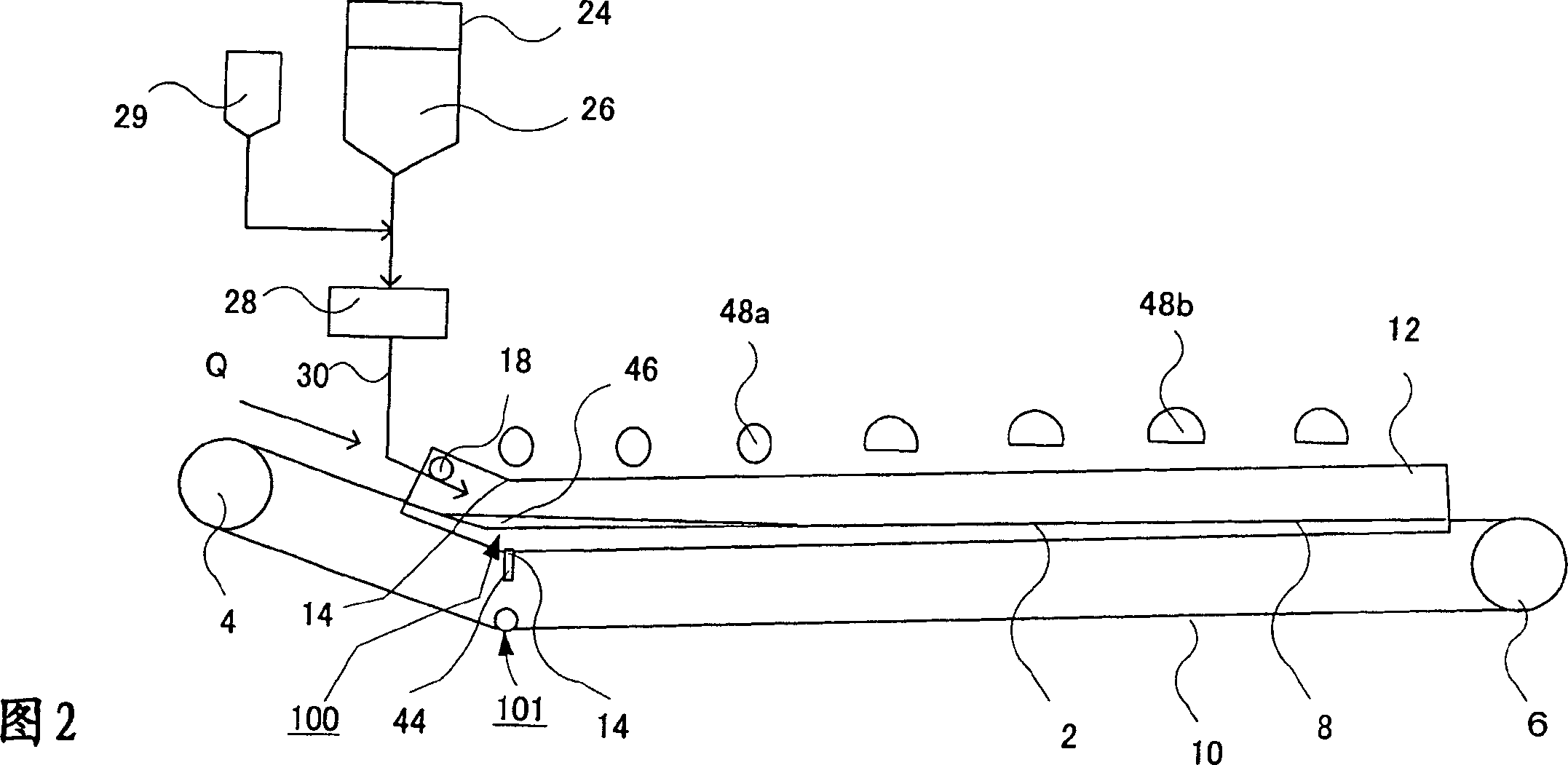

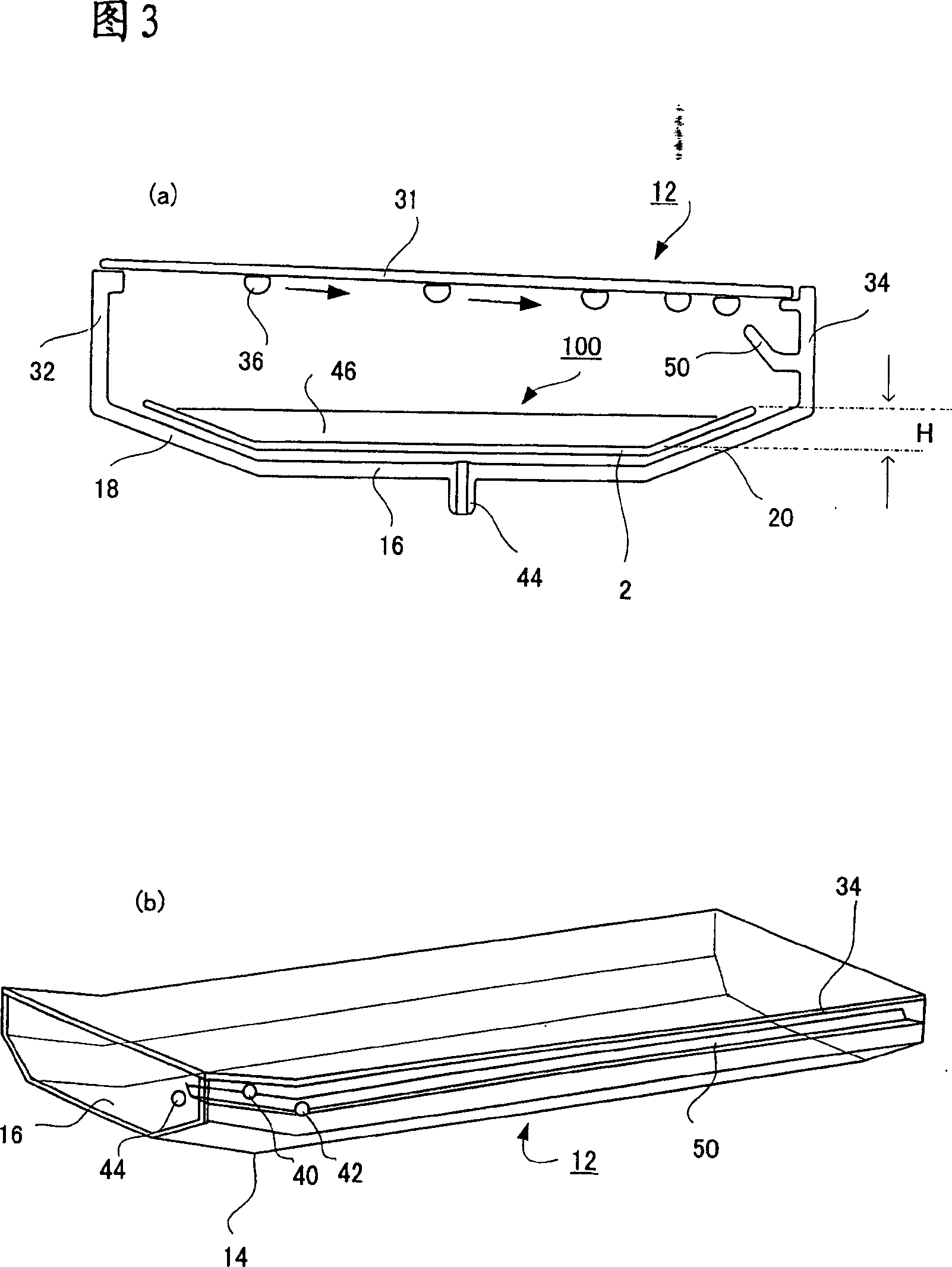

[0098] The polymerization of the water-soluble vinyl monomer was carried out using the apparatus shown in FIG. 2 . In addition, the angle α of the bending portion 100 on the continuous belt is 160 degrees, and the angle θ with the horizontal plane is 2.5 degrees. Similarly, the bending angle of the bending portion 14 of the airtight chamber is 160 degrees. The downstream length is 3m and the inclination angle of this part is 2.5 degrees. The continuous belt 2 is a belt obtained by compounding a polyester resin woven belt surface with a fluororesin.

[0099] Distilled water was added to a monomer mixture of 90 mol% of acrylamide and 10 mol% of adducted methyl chloride of dimethylaminoethyl acrylate (hereinafter referred to as "DAC") to obtain a monomer with a monomer concentration of 32% by mass. Aqueous solution 850g. After adjusting the pH to 4.0, nitrogen gas was blown for 30 minutes while maintaining the temperature at 10°C. T...

Embodiment 2

[0109] (Manufacture of water-absorbent resin)

[0110] The polymerization of the water-soluble vinyl monomer was carried out using the apparatus shown in FIG. 2 . In addition, the angle α of the bending portion 100 of the continuous belt is 160 degrees, and the angle θ with the horizontal plane is 2.5 degrees. Similarly, the bending angle of the bending portion 14 of the airtight chamber is 160 degrees. From the bending portion 14 to the most downstream of the airtight chamber The length is 3m, and the inclination angle of this part is 2.5 degrees. The continuous belt 2 is obtained by coating and impregnating a silicone resin on the surface of a belt woven with polyester resin.

[0111] In the mixture of 25 mol% of acrylic acid and 75 mol% of sodium acrylate, trimethylolpropane triacrylate 300ppm (to the total mass of monomers) as a crosslinking agent was added, distilled water was added to make the total mass 850 g and a monomer concentration of 40% by mass to obtain a mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com