Polysilicon film for film transistor and display device with the polysilicon film

A technology of polysilicon thin films and display devices, applied in transistors, electric solid state devices, semiconductor devices, etc., can solve problems such as lack of accuracy of the number of main grain boundaries, insufficient embedded circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the invention will now be set forth in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. Embodiments of the present invention will be described below with reference to the drawings.

[0038] Since the grains have a finite size, grain boundaries are formed between adjacent grains. If the crystal grains of polysilicon exert an important influence directly or indirectly on TFT characteristics when preparing TFTs for active matrix displays, the polysilicon crystal grains can be enlarged and adjusted to improve TFT characteristics.

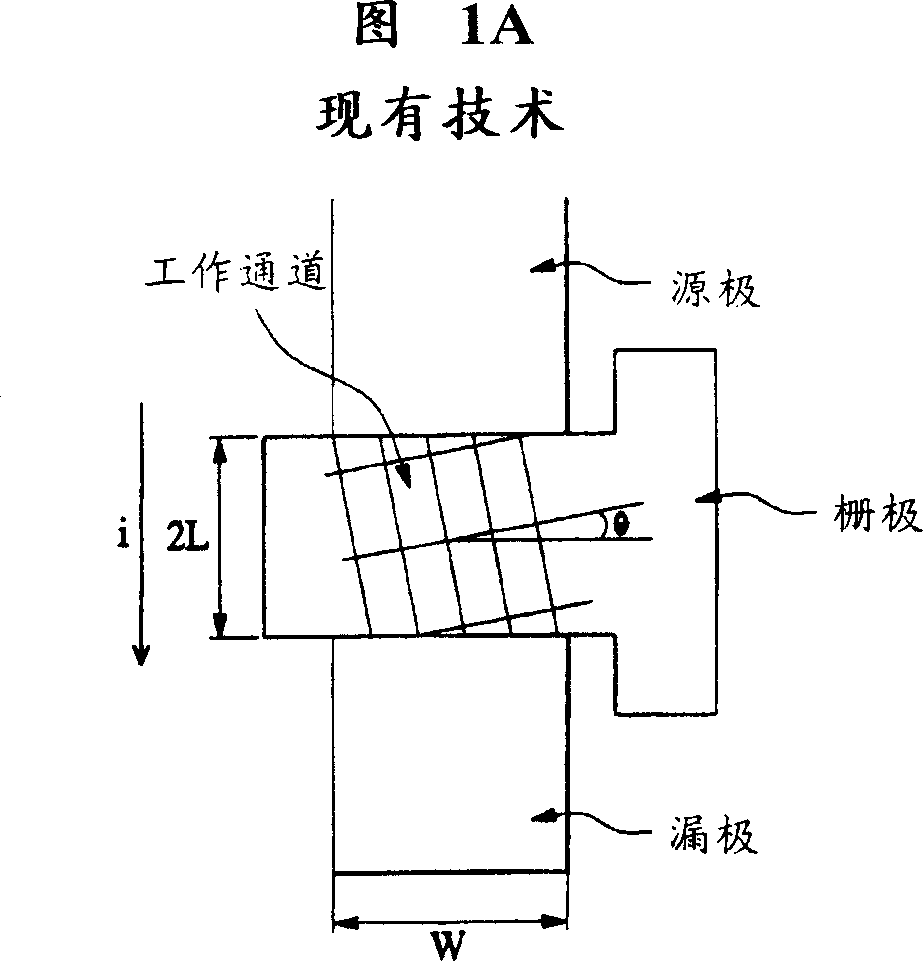

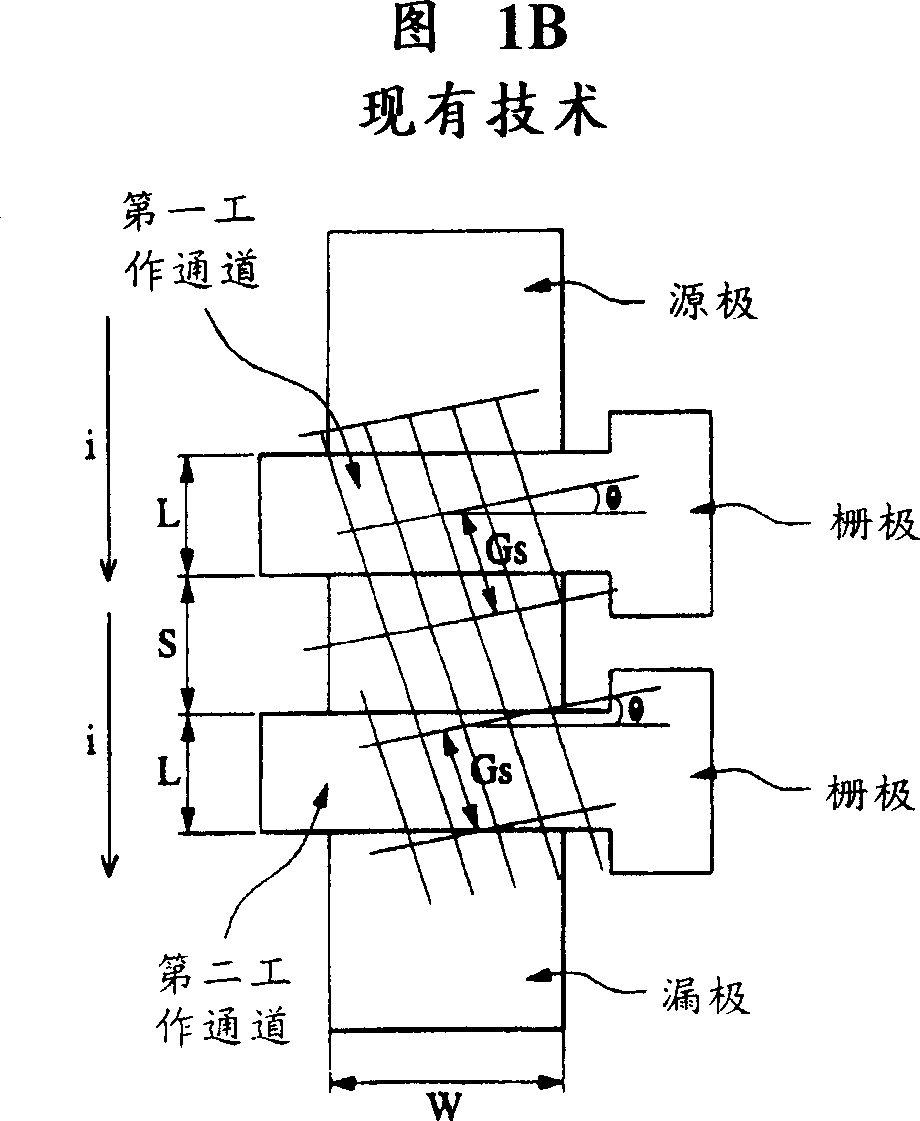

[0039] The grain boundaries that exist in the working channel region exert a significant influence on the TFT characteristics, especially the "primary" grain boundaries with an inclination angle of -45°≤θ≤45° along the direction perpendicular to the working channel, as shown in Figure 1A and Fig. As shown in 1B, unavoidable defects are includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com