Multi-loop modulus mixing electrohydraulic controlled stokehold formation machine

A technology of modulus mixing and electro-hydraulic control, which is applied in the direction of block/powder fuel preparation, combustion method, combustion equipment, etc., can solve the problems of excessive sulfur dioxide and smoke and dust emissions, unreasonable, low combustion efficiency, etc., and achieve convenient maintenance , Increased control accuracy and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

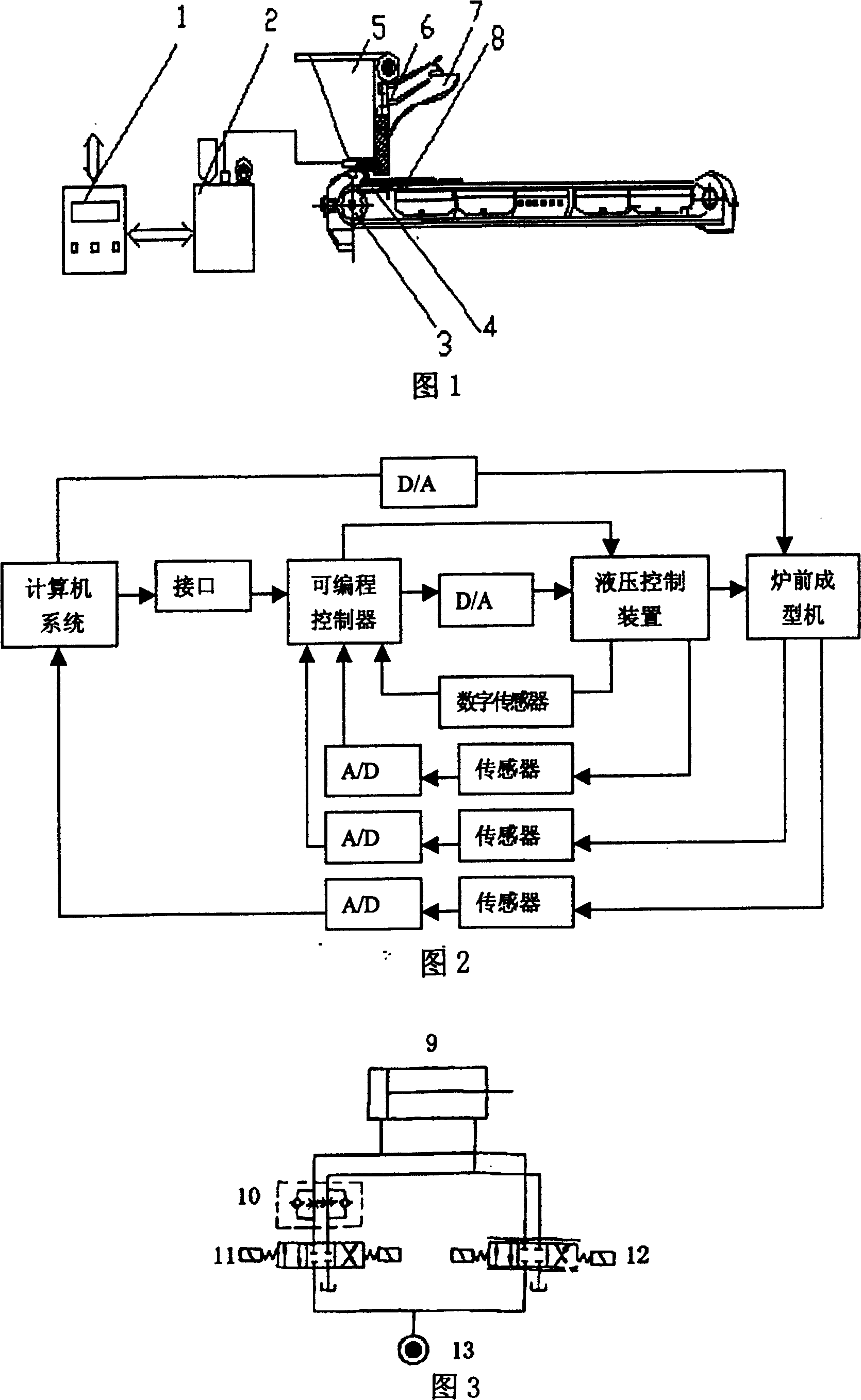

[0015] The multi-circuit modulus hybrid electro-hydraulic control furnace front forming machine has a coal hopper 5, a roller, a motor and a reducer device 4, a coal gate 6, a front arch 7, a drive sprocket 3, and a chain or a fixed grate 8; , high-precision modulus hybrid control system 1, electro-hydraulic control system 2 for automatic control of the forming strength and the operation of the furnace former forming machine; the driving shaft is a transverse axial groove, the driven shaft is a longitudinal circumferential groove, the pressed shape The coal is two intersecting arc surfaces; the briquette pressure can be adjusted from 30 to 150kg / cm 2 .

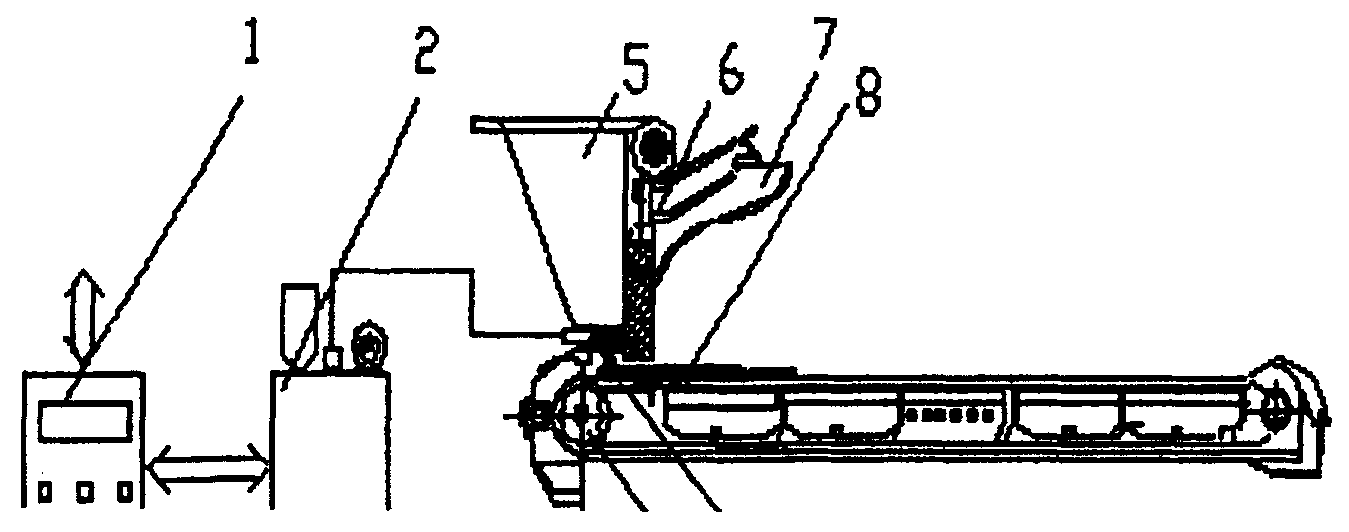

[0016] The so-called programmable controller control system uses the computer system to control the hydraulic control device through the interface circuit and the programmable controller through analog-to-digital conversion, and controls the hydraulic control device through digital sensors and analog sensors. Carry out real-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com