Method for removing unreacted alcohols from esters products mixture utilizing rotating packed bed

A technology of rotating packed bed and product mixture, which is applied in the separation/purification of carboxylate, organic chemistry, etc., to achieve the effect of improving industrial utilization value, improving the quality of ester products, and shortening the removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

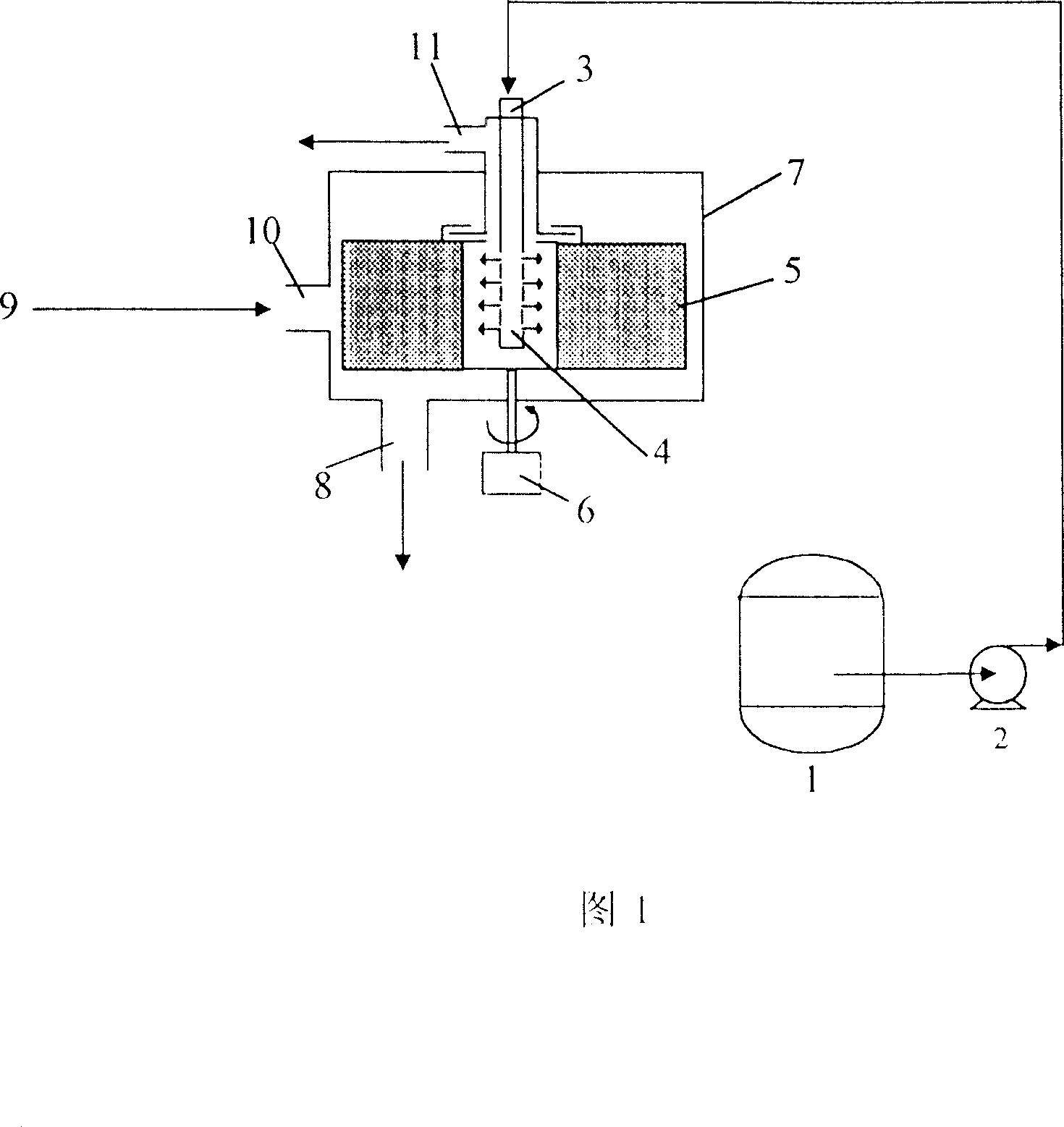

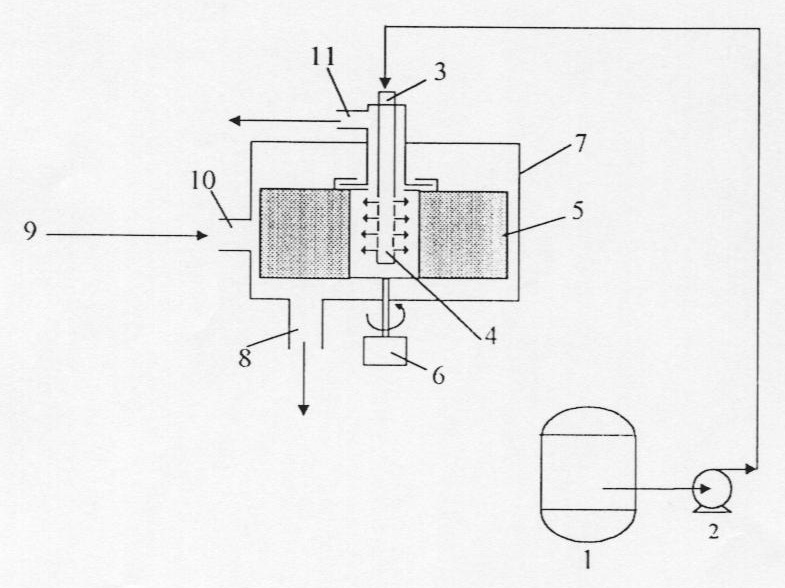

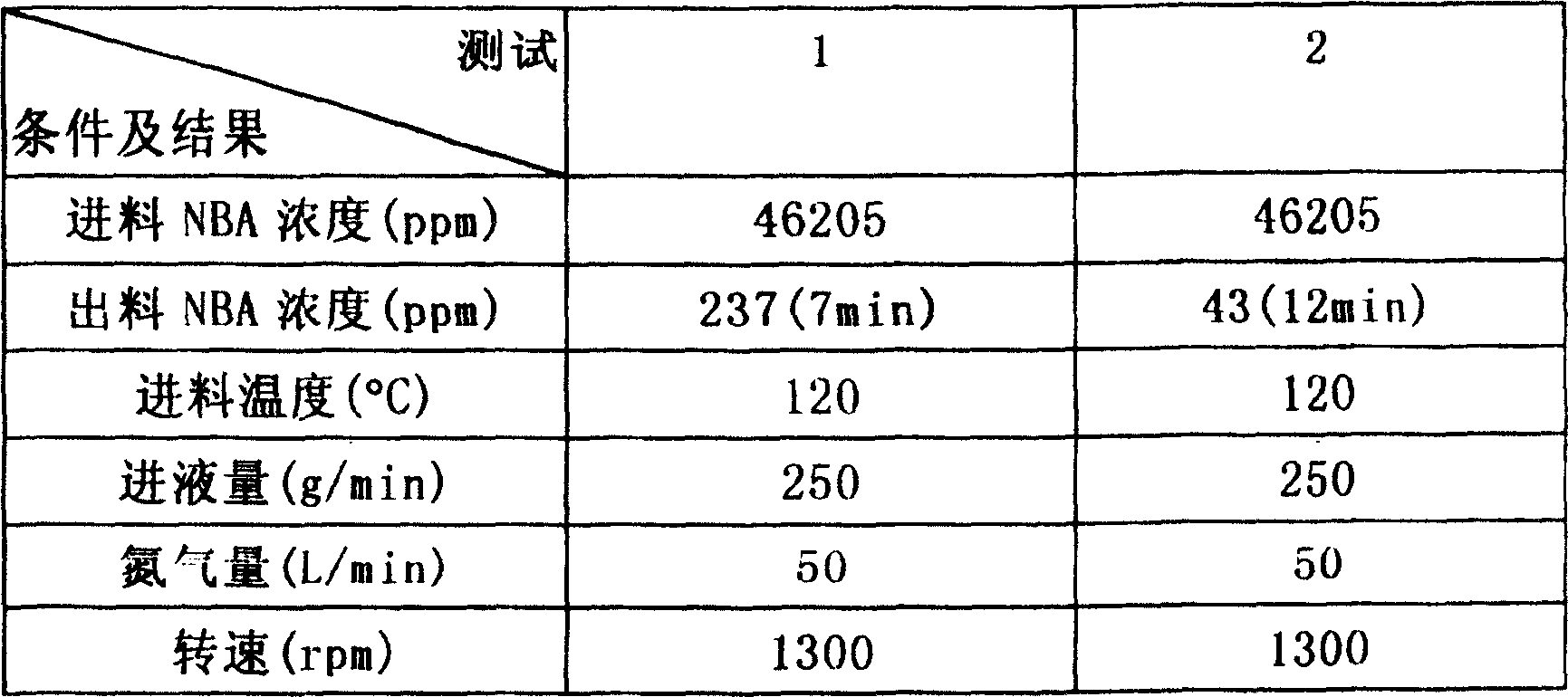

[0028] Butyl stearate (BST) batch n-butanol removal (NBA) tests were performed using a system similar to that of Figure 1 . The specifications of the rotating packed bed are: inner diameter 78mm, outer diameter 160mm, thickness 20mm. The speed is fixed at 1300rpm. The filling used is woven stainless steel wire mesh (specific surface area 1906m 2 / m 3 ). The filling porosity of the rotating packed bed is 0.91 (the porosity is 1 when the filling is not filled; the filling porosity is 0 when it is completely filled), and nitrogen is used as the degassing agent. During the experiment, the BST was fed into the rotary packed bed from the liquid inlet 3 and the liquid product from the liquid outlet 8 was introduced into the material tank 1 to return to the material tank 1. The experimental conditions and the obtained results are shown in the table. It can be found from this table that the NBA of the purified product sampled from the liquid outlet 8 at the 7th minute dropped to 2...

Embodiment 2

[0030] A continuous n-butanol removal (NBA) test for butyl stearate (BST) was performed using a system similar to that of Figure 1 . The specifications of the rotating packed bed are: inner diameter 20mm, outer diameter 40mm, thickness 20mm. The speed is fixed at 1300rpm. The filler used is woven stainless steel wire mesh with a specific surface area of 1546m 2 / m 3 . The packing porosity of the rotating packed bed is 0.90. Use water vapor as a degassing agent, and operate at low pressure with the aid of gas inlet 10 to pump air. During the experiment, the BST was fed into the rotating packed bed from the liquid inlet 3 and the purified product was collected from the liquid outlet 8 . The experimental conditions and the obtained results are shown in the table. From this table, it can be found that continuous treatment at low pressure by a rotating packed bed can reduce NBA to 43-49ppm.

Embodiment 3

[0032] Except that using isooctyl palmitate (EHP) instead of BST as the feed, the steps of Example 2 were repeated to carry out the test of continuous removal of 2-octanol (2-EH). The experimental conditions and the obtained results are shown in the table. From this table, it can be found that continuous treatment at low pressure through a rotating packed bed can reduce 2-EH to below 100 ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com