Desulfuration, denitration and energy conservation integrated purification system for coke oven flue gas and control method of system

A coke oven flue gas, desulfurization and denitrification technology, which is applied in the field of metallurgical industry, can solve the problems of increasing energy consumption, and achieve the effects of ensuring safe production, low flue gas resistance, and saving externally supplied fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

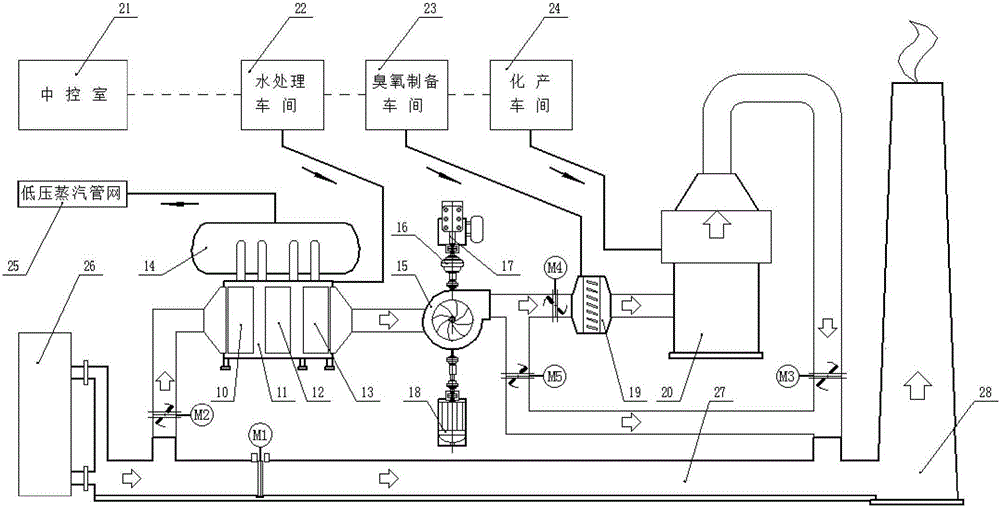

[0029] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0030] See figure 1 , a desulfurization and denitrification energy-saving integrated purification system for coke oven flue gas, comprising a waste heat recovery device, a circulating fan 15, an internal combustion engine 17, a pre-oxidation mixing device 19, and a desulfurization and denitrification reaction tower 20; the flue gas inlet of the waste heat recovery device is connected through a pipeline The flue gas discharge pipe of the coking oven 26, the flue gas outlet of the waste heat recovery device is connected to the circulation fan 15 through the pipe, the output end of the circulation fan 15 is connected to the pre-oxidation mixing device 19 through the pipe, and the flue gas outlet of the pre-oxidation mixing device 19 is connected to the desulfurization device through the pipe. The denitrification reaction tower 20 is connected to the chimney 28 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com