Pipeline type powder bunker electrostatic remover

A static eliminator and powder technology, applied in the direction of static electricity, electrical components, conveying bulk materials, etc., can solve problems such as low reliability, inconsistent critical charge-to-mass ratio, and loss of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

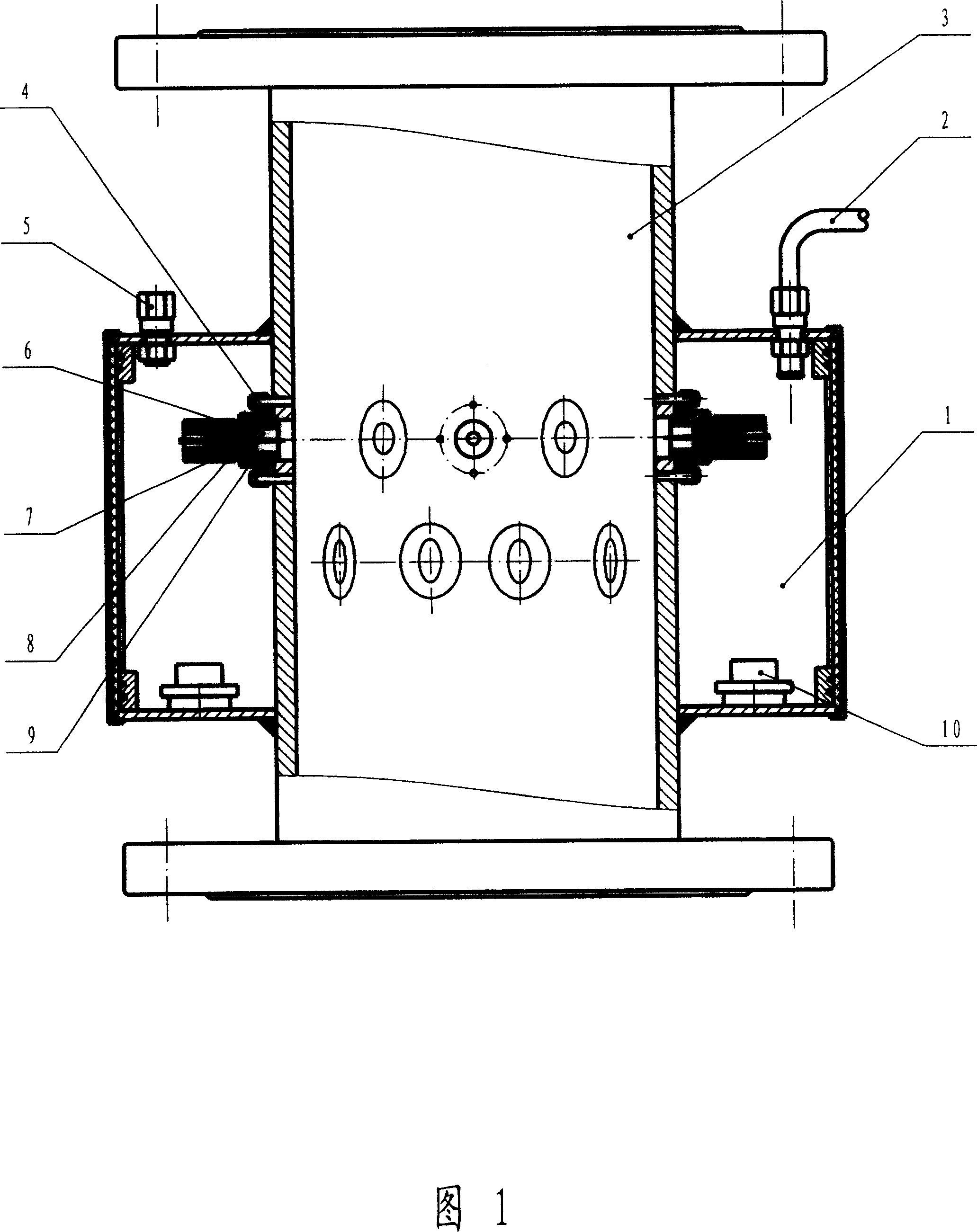

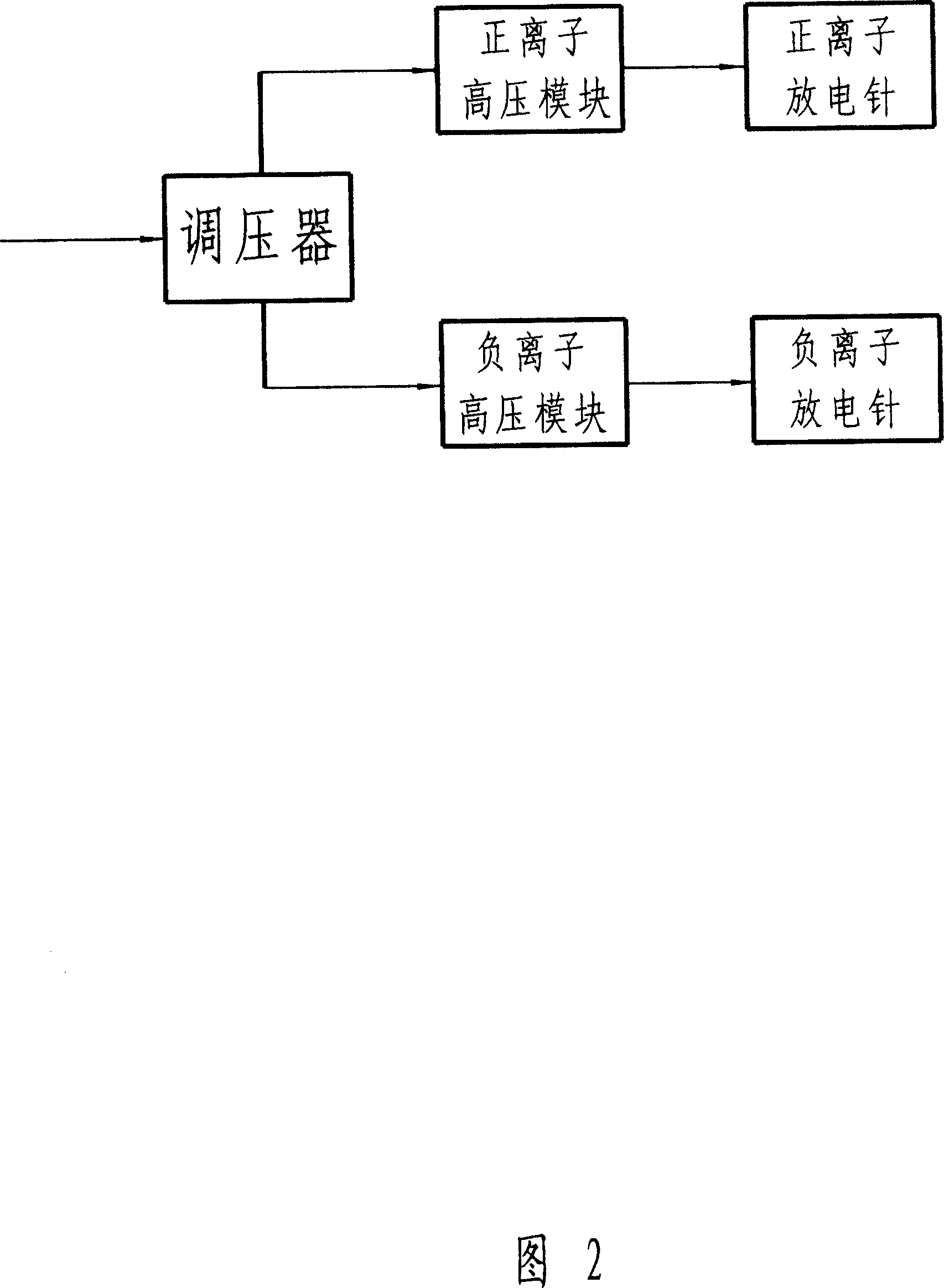

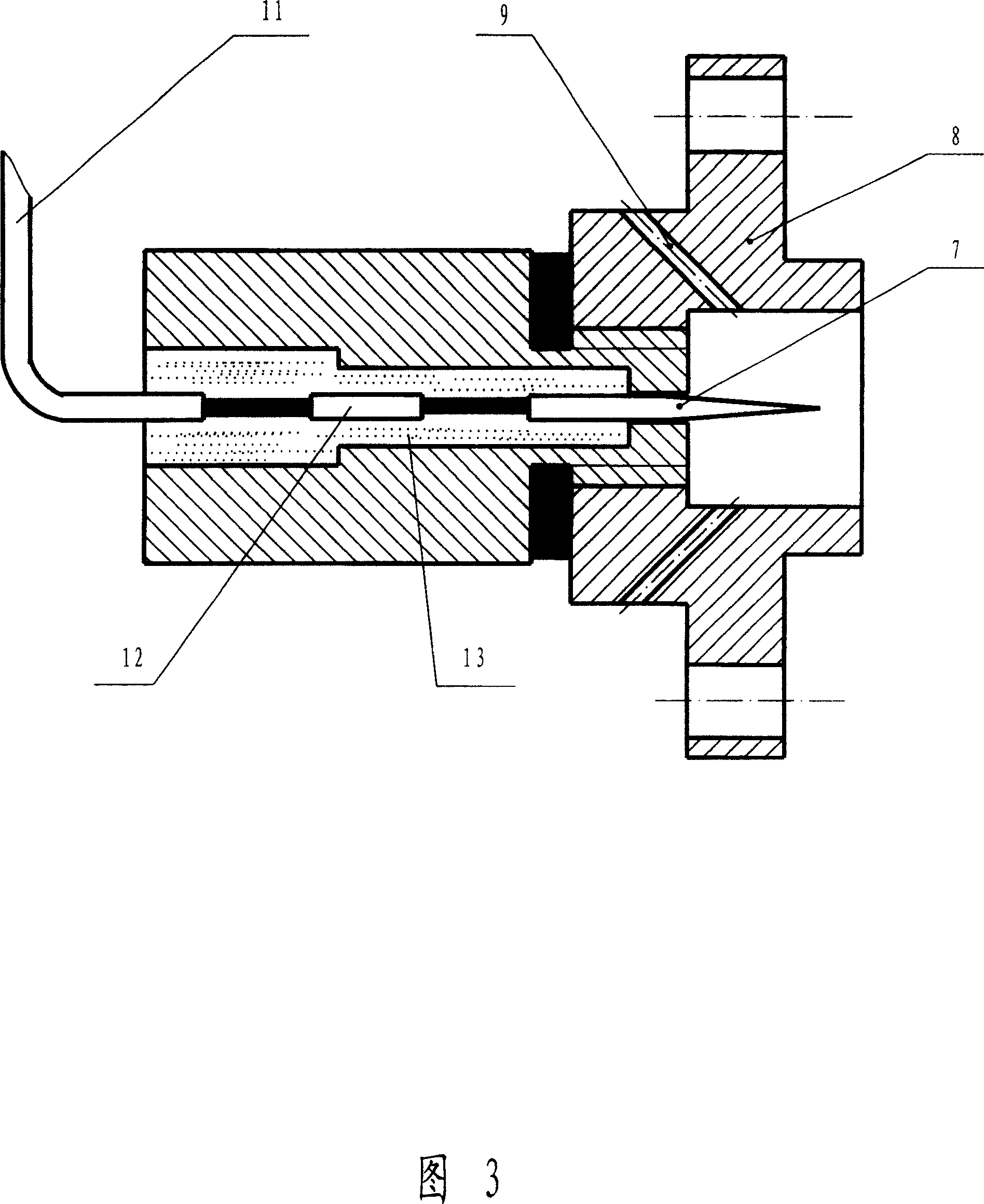

[0011] In the pipeline-type powder silo static eliminator shown in Figure 1, a ring-shaped positive pressure air chamber 1 is sleeved on the outer wall of the air-delivered material delivery pipe 3, and the positive pressure air chamber 1 is provided with a high-pressure air source connected to it. The air supply port 2, the high-voltage module 10 and the cable joint 5 are also arranged on the positive pressure air chamber 1; on the outer wall of the feeding pipe 3 in the positive pressure air chamber 1, two discharge electric needles 7 are arranged along the circumference of the wall, and each row There are eight discharge needles 7, and the discharge needles for positive ion discharge and negative ion discharge are arranged alternately at intervals; the discharge needles between the two rows are also vertically staggered, and this symmetrical arrangement is conducive to positive and negative discharge. The ions diffuse evenly into the delivery pipe, thereby enhancing the effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com