Prepn of nano-cobaltosic oxide powder

A nano-powder and cobalt salt technology, applied in the direction of cobalt oxide/cobalt hydroxide, cobalt carbonate, etc., can solve the problems of chemical composition, purity, particle size, crystal form, etc., and achieve easy control of parameters and simple process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

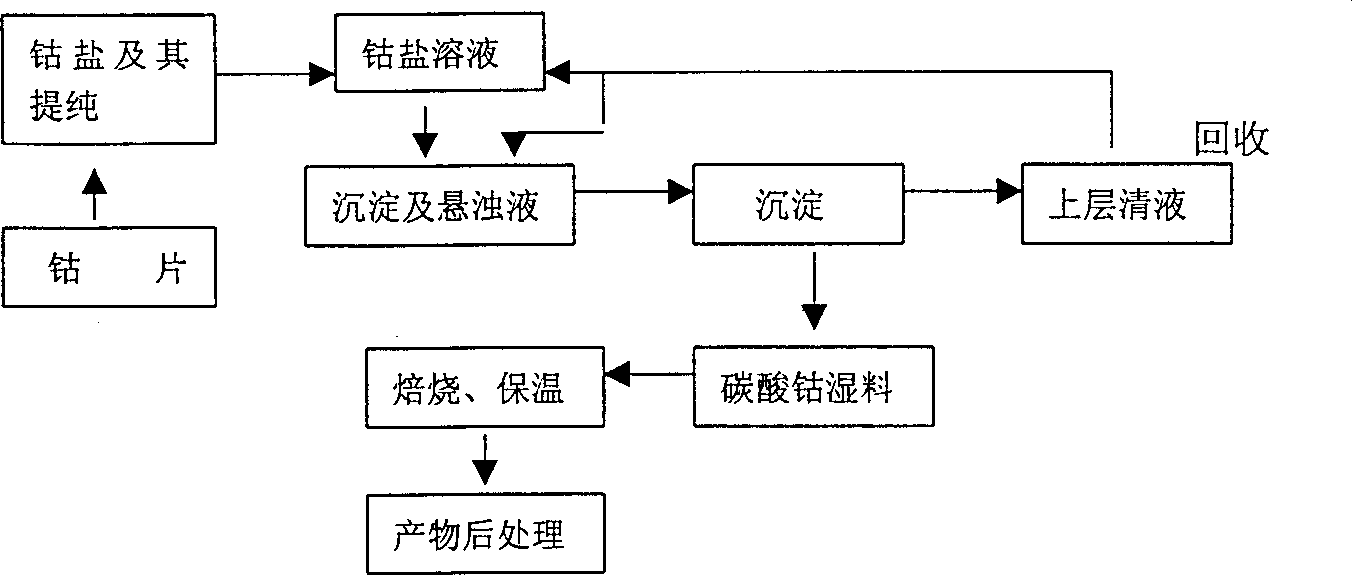

Method used

Image

Examples

Embodiment 1

[0045] First, the cobalt flakes are dissolved in nitric acid with a volume ratio of 1:1 under heating conditions, and high-purity water is continuously added during the dissolution process to adjust the density and pH of the solution, and finally a density of 1.35 g / cm is obtained. 3 1. Cobalt nitrate solution with a pH value of 4.5, let it stand for a day, filter to remove the solid precipitate; then adjust the pH of the solution to 1.5 with nitric acid, carefully evaporate the solvent to obtain a cobalt nitrate solution with a density of 1.57, let it stand, cool, and precipitate Cobalt nitrate crystals. Analysis shows that the content of Fe element in the cobalt nitrate crystal is lower than 0.004%, and the content of Ni element is lower than 0.025%.

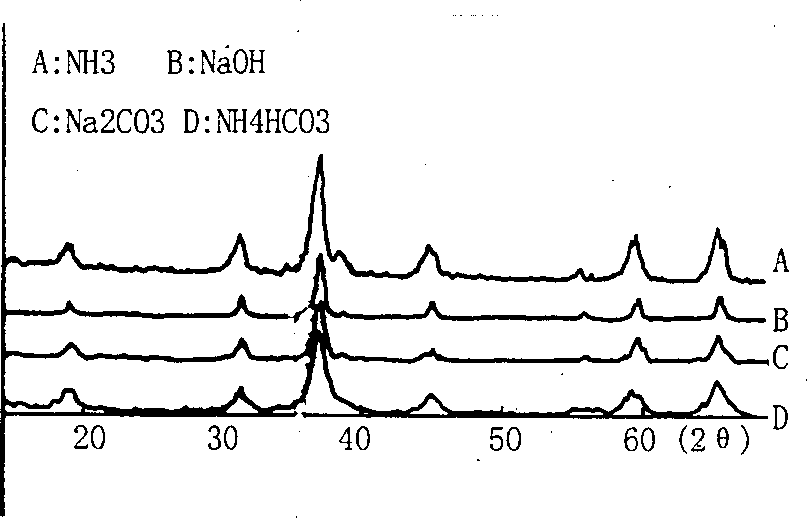

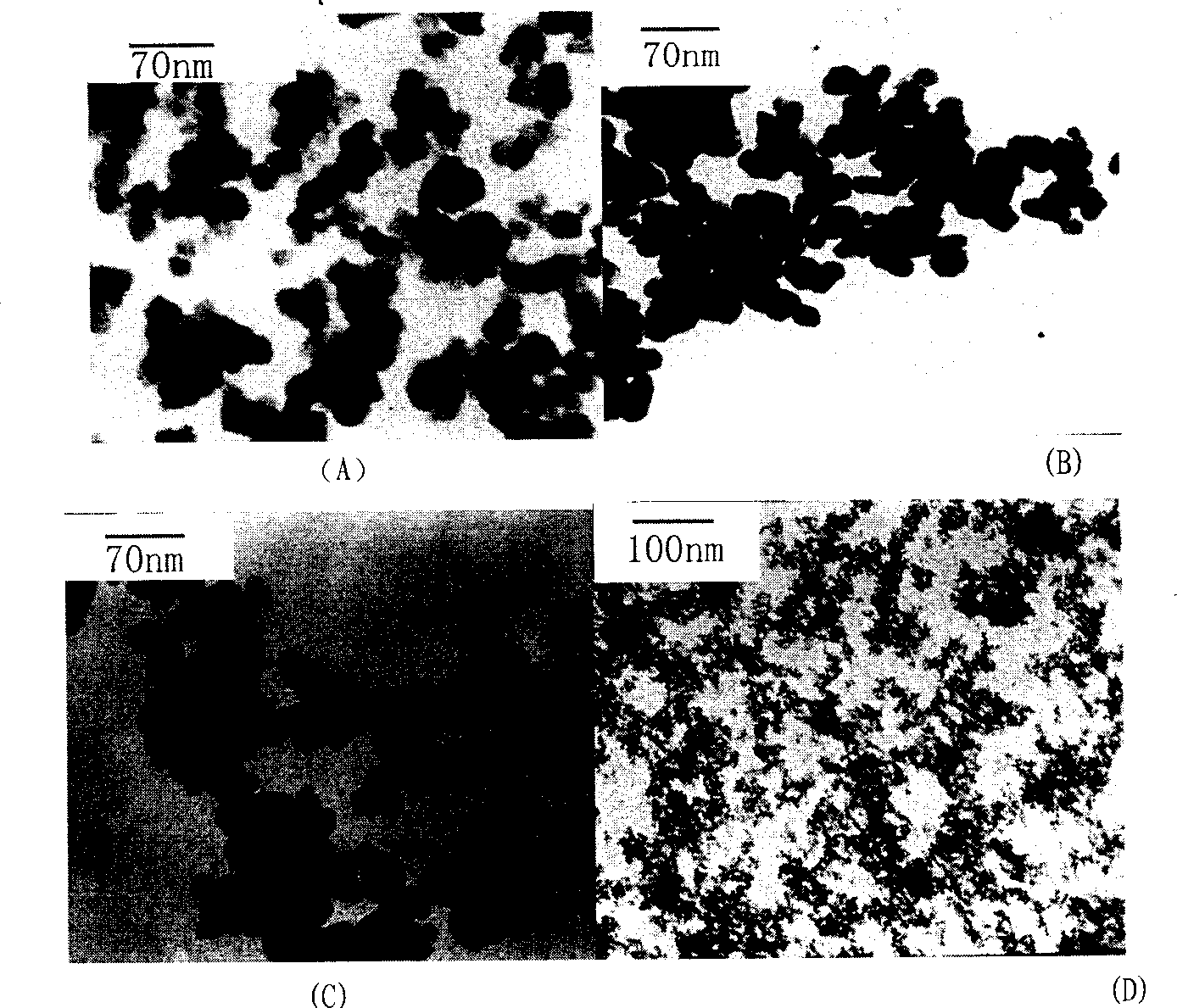

[0046] The chemical precipitant uses food grade NH 4 HCO 3 , the content of Na element is less than 0.02%. With 25 parts by weight (parts by weight, the same below) ammonium bicarbonate and 100 kilograms of high-purity wate...

Embodiment 2

[0049] Embodiment 2. As described in embodiment 1, the difference is:

[0050] Make the ammonium bicarbonate suspension that concentration is 14.3% weight percent with 25 parts of ammonium bicarbonate and 150 kilograms of high-purity water stand-by. Under stirring conditions, slowly add purified ammonium bicarbonate with a density of 1.60g / cm2 to the suspension of ammonium bicarbonate 3 solution of cobalt nitrate so that the weight ratio of substances:CO 3 2- / Co 2+ = 2.6, and adjust the pH of the supernatant after the reaction to 6.7. After the addition was complete, stirring was continued for 2.5 hours. Let stand and centrifuge. The solid cobalt content is controlled at 21%, and the separated clear liquid is recycled. Put the cobalt carbonate wet material obtained in the previous step into an appropriate container, raise the temperature to 400°C and keep it warm for 3.5 hours to obtain a black powder.

[0051] This process uses cobalt flakes and ammonium bicarbonate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com