Process for producing hard phase strengthened metal base composite material

A composite material and production process technology, which is applied in the field of hard phase reinforced metal matrix composite material production technology, can solve the problem of inability to produce thin-walled bimetallic hard phase reinforced metal materials, reduce the mechanical properties and wear resistance of materials, and cannot For the production of large workpieces and other problems, achieve the effect of uniform fine crystal structure, good performance consistency, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

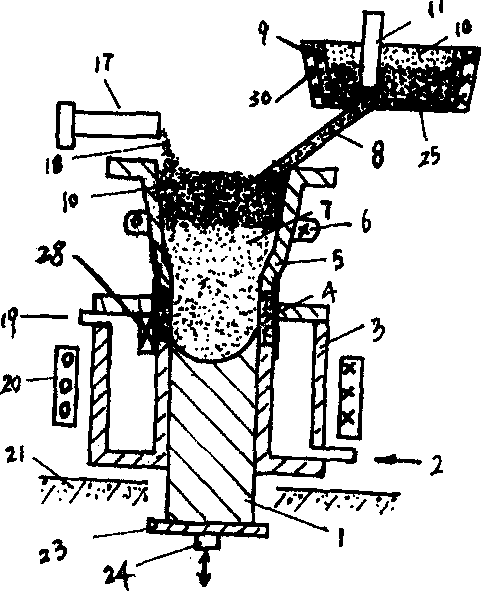

[0019] Example 1: In figure 1 Among them, the equipment has a workbench 21, a hole is arranged on the workbench 21, there is a casting plate 23 and a casting plate lifter 24 in the hole, a water-cooled crystallizer 3 is connected to the workbench 21, and a water-cooled crystallizer 3 is installed outside the hole The electromagnetic stirrer 20 is connected with a feeder 17 and a tundish at the top of the water-cooled crystallizer 3 . The tundish includes a bag body 9, a control valve 11, a launder 8 and a heater 30. There is a heater 30 outside the bag body 9, a control valve 11 is connected inside the bag body 9, and a launder is connected to the bottom of the bag body 9. 8. The launder 8 communicates with the control valve 11. The water-cooled crystallizer 3 has a water tank, the center of the water tank has a straight cylindrical through hole, the bottom of the water tank is connected with the cooling water inlet 2, the top is connected with the cooling water outlet 19, an...

Embodiment 2

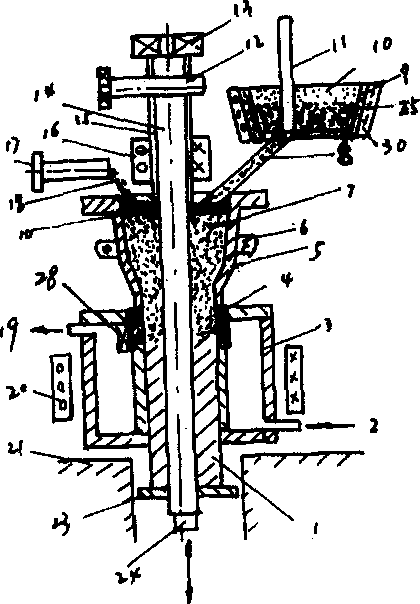

[0021] Example 2: In figure 2 Among them, the inner cavity of the water-cooled crystallizer 3 is equipped with a mandrel 14 of metal or non-metallic material, and a mandrel holder 13 is connected to the upper end of the mandrel 14; an ultrasonic vibration device 12 is installed below the mandrel holder 13; The surface of the mandrel 14 is coated with a glass protective film 15 to prevent oxidation; a preheating induction heater 16 is installed in the middle to preheat the mandrel 14, and when the mixed liquid 7 is poured, the glass coated on the surface of the mandrel 14 The protective film 15 melts and floats up after being stirred by the electromagnetic stirrer 20, exposing the clean surface of the mandrel 14, and achieves good metallurgical bonding with the reinforced hard phase metal matrix composite material 1 to form a bimetallic hard phase reinforced metal matrix composite material 1. The ultrasonic vibration device 12 performs ultrasonic vibration treatment on the mi...

Embodiment 3

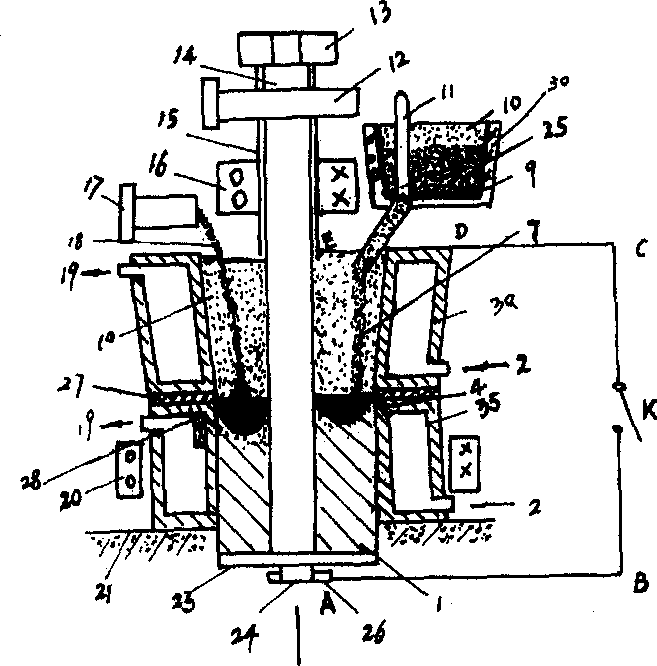

[0022] Example 3: In image 3 Among them, the water-cooled crystallizer or a combined water-cooled crystallizer is composed of a conductive water-cooled crystallizer 3a, a non-conductive water-cooled crystallizer 35, a high-temperature insulating pad 27, a high-temperature-resistant conductive ceramic, and a non-metal slow cooling sleeve. The conductive water-cooled crystallizer The device 3a is located at the top of the non-conductive water-cooled crystallizer 35, and a high-temperature-resistant insulating pad 27 is connected between the conductive water-cooled crystallizer 3a and the non-conductive water-cooled crystallizer 35, and a layer of high-temperature-resistant conductive ceramics is coated on the inner wall of the conductive water-cooled crystallizer 3a. The top of the non-conductive water-cooled crystallizer 35 is equipped with a non-metal slow cooling jacket. A mandrel 14 is installed in the inner cavity of the combined water-cooled crystallizer, the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com