Method of measuring liquid component, liquid component, printing ink set, method of forming coloured part on recording medium and ink jet recording

A technology for liquid components and ink sets, which is applied in the fields of measuring liquid components, liquid components, ink sets, forming colored parts on recording media and inkjet recording, and can solve the problem of uneven image, uneven distribution, fixed problems such as insufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0211] Because the preparation method of its hydrophobic group cationic self-dispersing carbon black is illustrated by the method of introducing an N-ethylpyridine group into a kind of pigment:

[0212] Carbon black was treated with 3-amino-N-ethylpyridine bromide.

[0213] Because the pigment that is cationic by introducing a hydrophobic group into the surface of the pigment in the above-mentioned manner shows excellent dispersibility in water due to the repulsion between ions, even when it is contained in an aqueous ink without adding any dispersant or In the case of analogues, a stable dispersion state can still be maintained. Carbon black is particularly suitable as pigment.

[0214] On the other hand, in order to obtain an ink having desired physical properties, a surfactant, an antifoaming agent, or a preservative may be added to the ink in addition to the above-mentioned ingredients. The ink may contain a commercially available water-soluble material.

[0215] Ex...

example 1 to example 8

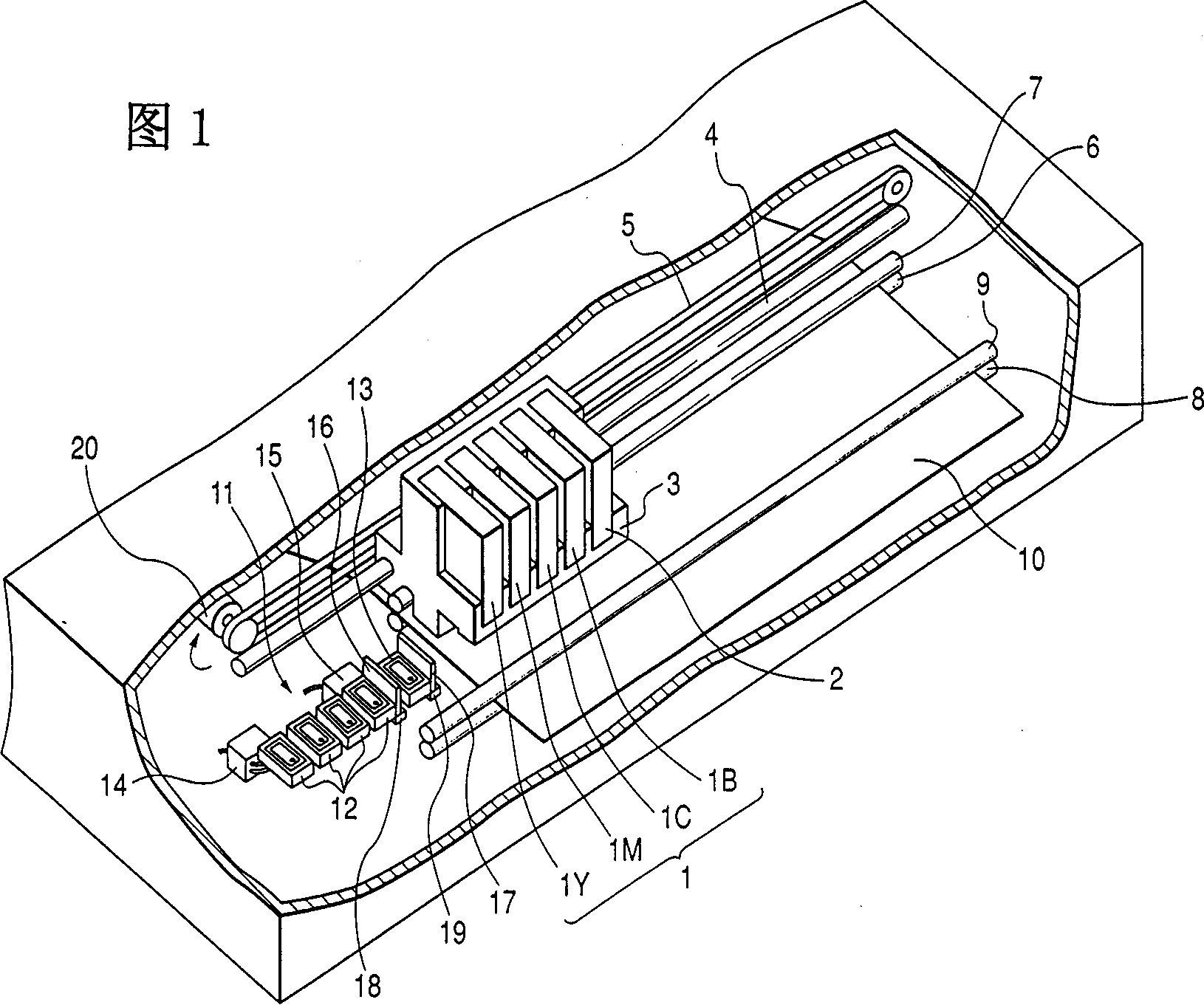

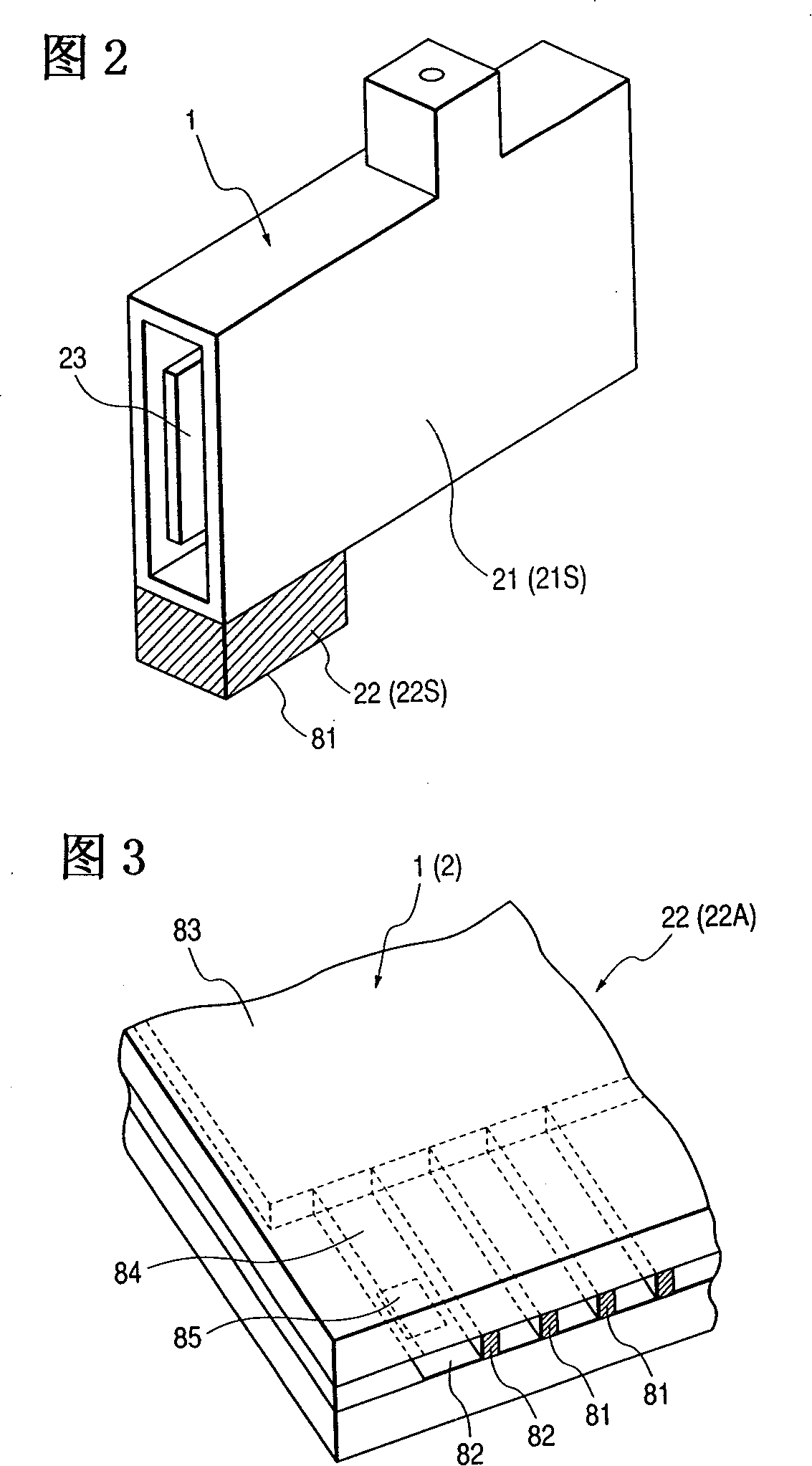

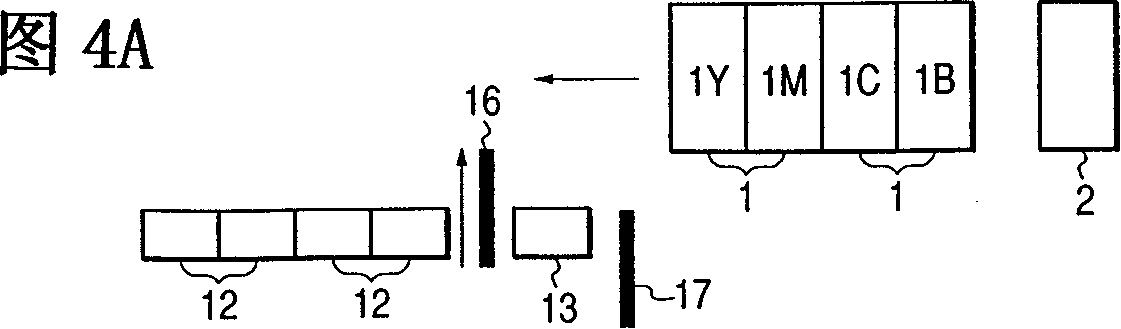

[0352] In Examples 1 to 8, a color image was formed on PPC paper (manufactured by Canon Corporation) using a combination of liquid components A to D and ink sets 1 and 2. For printing, an inkjet recording apparatus as shown in FIG. 1 equipped with 5 recording heads as shown in FIG. 3 was used. At that time, the liquid component is applied to the recording paper before the ink is applied.

[0353] Actually, printing is done with 3-pass fine printing, and the printing area is scanned three times. At this time, each liquid component is applied to a position corresponding to one pixel, and any one of yellow, magenta, cyan, and black inks is applied to each pixel. That is, the logic of the print data for yellow, magenta, cyan, and black and the data applied as liquid components are employed in each printing. The type of fine mask used for fine printing is not particularly limited, and any known technique may be used. A detailed description is therefore omitted.

[0354] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com