Method for eliminating residual gas in field emission display and gas released by material

A technology of residual gas and display devices, which is applied in the manufacture of electrical components, discharge tubes/lamps, and cold cathodes, and can solve problems such as weakening of the tip field strength, reduction of emission current, and shortening of the life of field emission displays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

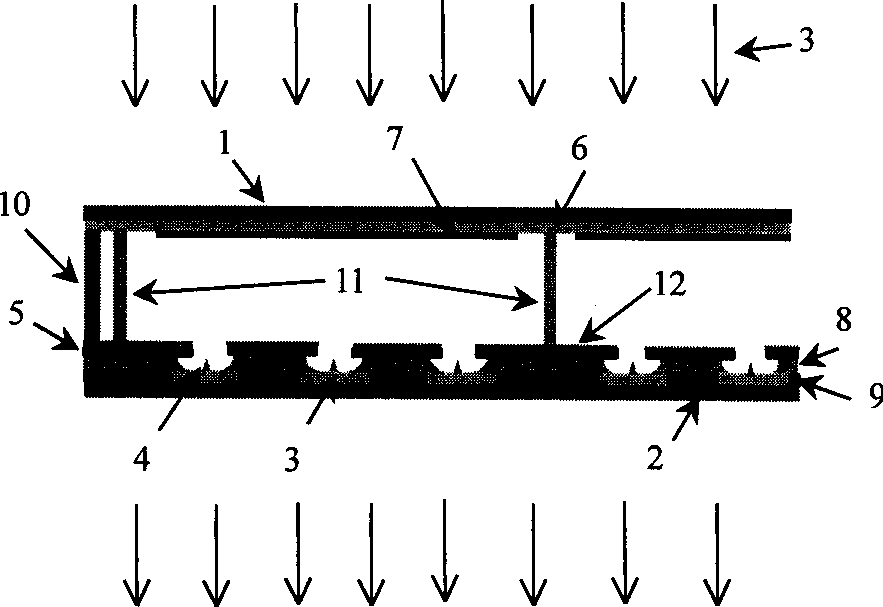

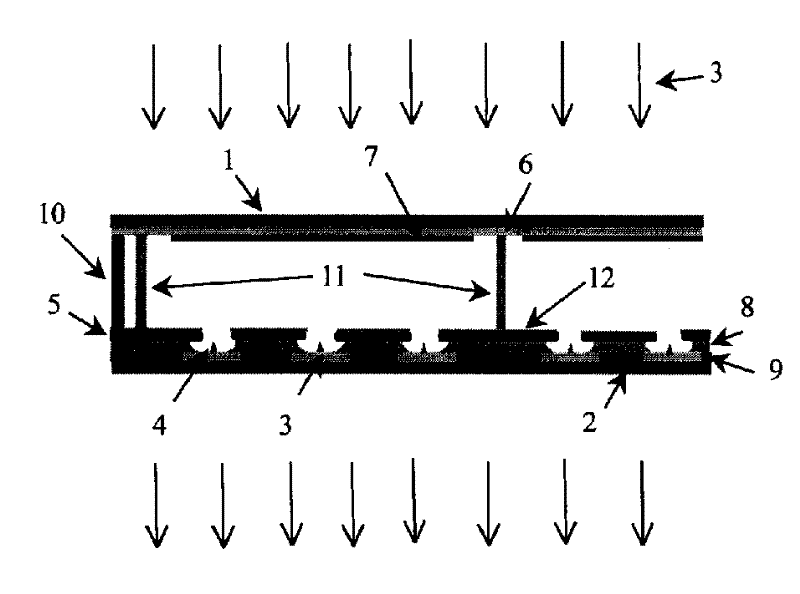

[0017] The field emission display includes a front glass substrate 1 as the effective display working surface of the display device and a rear glass substrate 2 parallel to the front glass substrate; multiple cathode electrodes 3 parallel to each other are arranged on the rear glass substrate and located at The micro-tip electron emitter 4 on which is kept electrically connected; the micro-tip electron emitter starts to emit electrons when its electric field reaches a certain intensity under the control of its corresponding gate electrode 5, and the emission current increases with the increase of the electric field intensity; The emitted electrons are accelerated toward the anode under the action of the transparent conductive anode 6 on the front substrate, and the anode and the cathode are arranged orthogonally; and after passing through a vacuum space, they bombard the phosphor powder 7 on the front substrate to make the phosphor emit light. Can be seen through the transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com