Nano level metal telluride preparing process

A nano-scale, telluride technology, applied in selenium/tellurium compounds, chemical instruments and methods, binary selenium/tellurium compounds, etc., can solve the problems of high reaction temperature and high cost of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

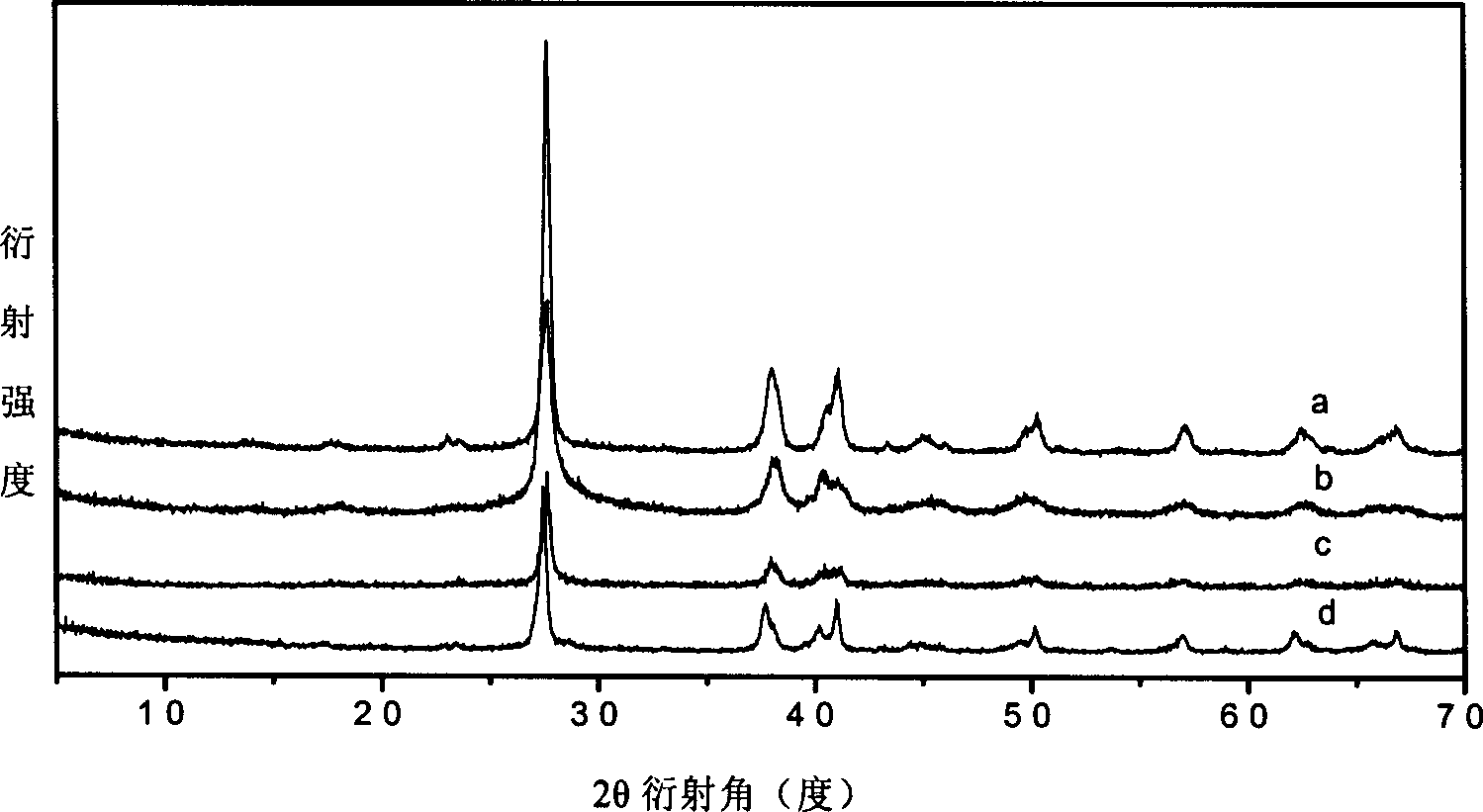

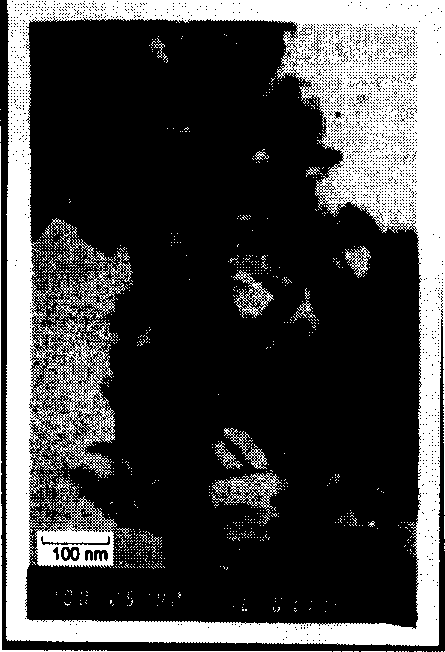

[0034] BiCl 3 2H 2 O (20mmol), Te powder (30mmol), KOH (90mmol) and KBH 4 (30mmol) into a 100ml autoclave, add solvent N,N-dimethylformamide (DMF) to 90% of its capacity, and react at 100°C for 24 hours. Cool naturally to room temperature, filter, wash thoroughly with water and ethanol, and dry in vacuum to obtain black Bi 2 Te 3 powder. Compound XRD spectrum see figure 1 a; the appearance is rod-shaped particles with a rod diameter of 10 nanometers and a length greater than 100 nanometers (see figure 2 ). ( figure 1 corrected)

Embodiment 2

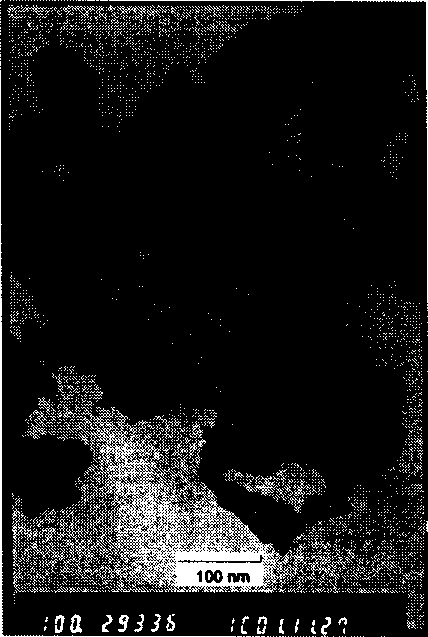

[0036] BiCl 3 2H 2 O (20mmol), Te powder (30mmol), KOH (120mmol) and KBH 4 (30mmol) into a 100ml autoclave, add solvent N,N-dimethylformamide (DMF) to 90% of its capacity, and react at 130°C for 24 hours. Naturally cooled to room temperature, filtered, thoroughly washed with water and ethanol, and dried in vacuum at 60°C to obtain black Bi 2 Te 3 powder. Compound XRD spectrum see figure 1 B; morphology is a spherical particle with an average particle diameter of 20 nanometers (see image 3 ).

Embodiment 3

[0038] Bi(NO 3 ) 3 ·5H 2 O (20mmol), Te powder (30mmol), KOH (160mmol) and KBH 4(30mmol) into a 100ml autoclave, add solvent N,N-dimethylformamide (DMF) to 80% of its capacity, and react at 100°C for 24 hours. Naturally cool to room temperature, filter, wash thoroughly with water and ethanol, and dry in vacuum at 80°C to obtain black Bi 2 Te 3 powder. Compound XRD spectrum see figure 1 c; morphology is a spherical particle with an average particle diameter of 20 nanometers (see Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com