Production method for copper-clad laminated sheet

A technology of copper clad laminate and manufacturing method, which is applied in the direction of multi-layer circuit manufacturing, lamination, lamination device, etc., can solve the problems of reducing the utilization rate of raw materials of products and deterioration of etching accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

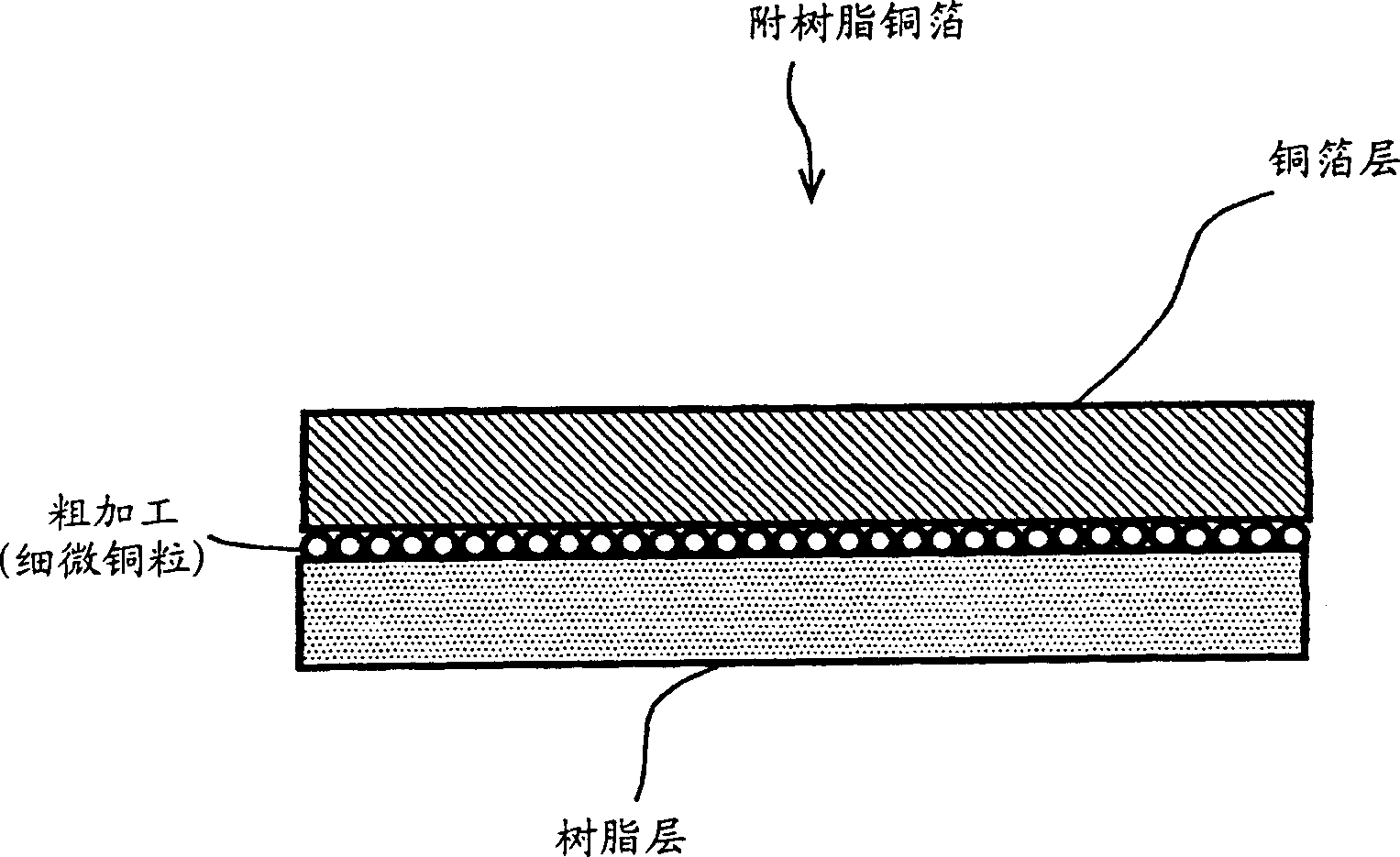

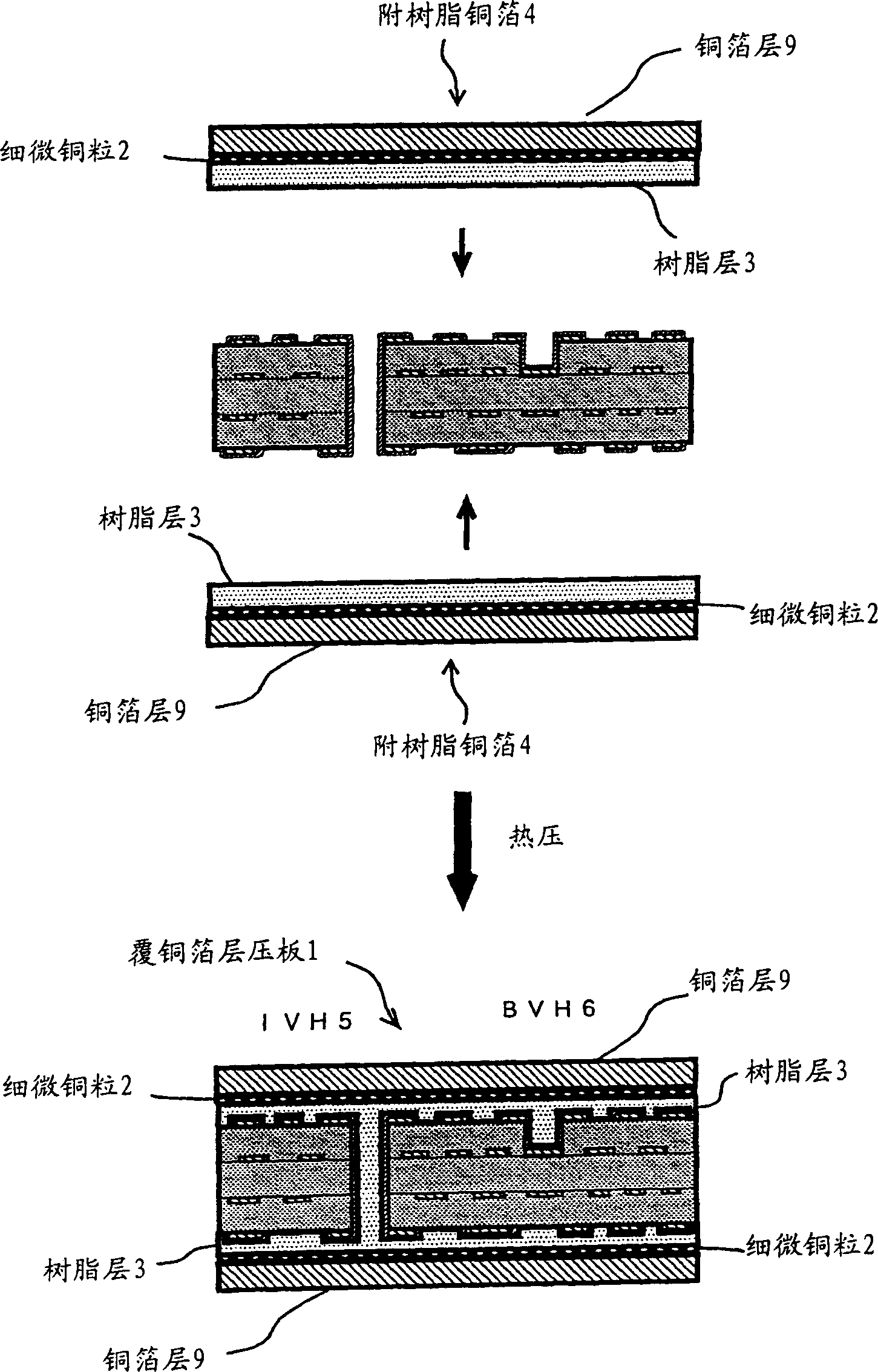

[0041] Here, the copper foil of claim 1 is used, that is, a VLP copper foil classified as a very low profile type foil with a thickness of 18 micrometers according to the IPC standard. The characteristic of this VLP copper foil is that the tensile strength is 52 kg / mm 2 , Vickers hardness is 150, the elongation after heating is 3.8%, the breaking strength measured by the pressure test after heating is 552 kN / m 2 .

[0042] A resin layer 3 with a thickness of 50 microns is formed on the rough surface of the VLP copper foil with fine copper particles 2 attached to form the copper foil 4 with resin. When forming the resin layer 3, use the following chemical reagents to dissolve in methyl ethyl ketone to form a resin composition with a solid content of 45%: bisphenol A epoxy resin (trade name: 60% by weight) EPOMIC R-301, manufactured by Mitsui Petrochemical Co., Ltd.), 20% by weight of rubber-modified epoxy resin (trade name: EPOTHOTOYR-102, manufactured by Toto Kasei Co., Ltd.) of 2...

Embodiment 2

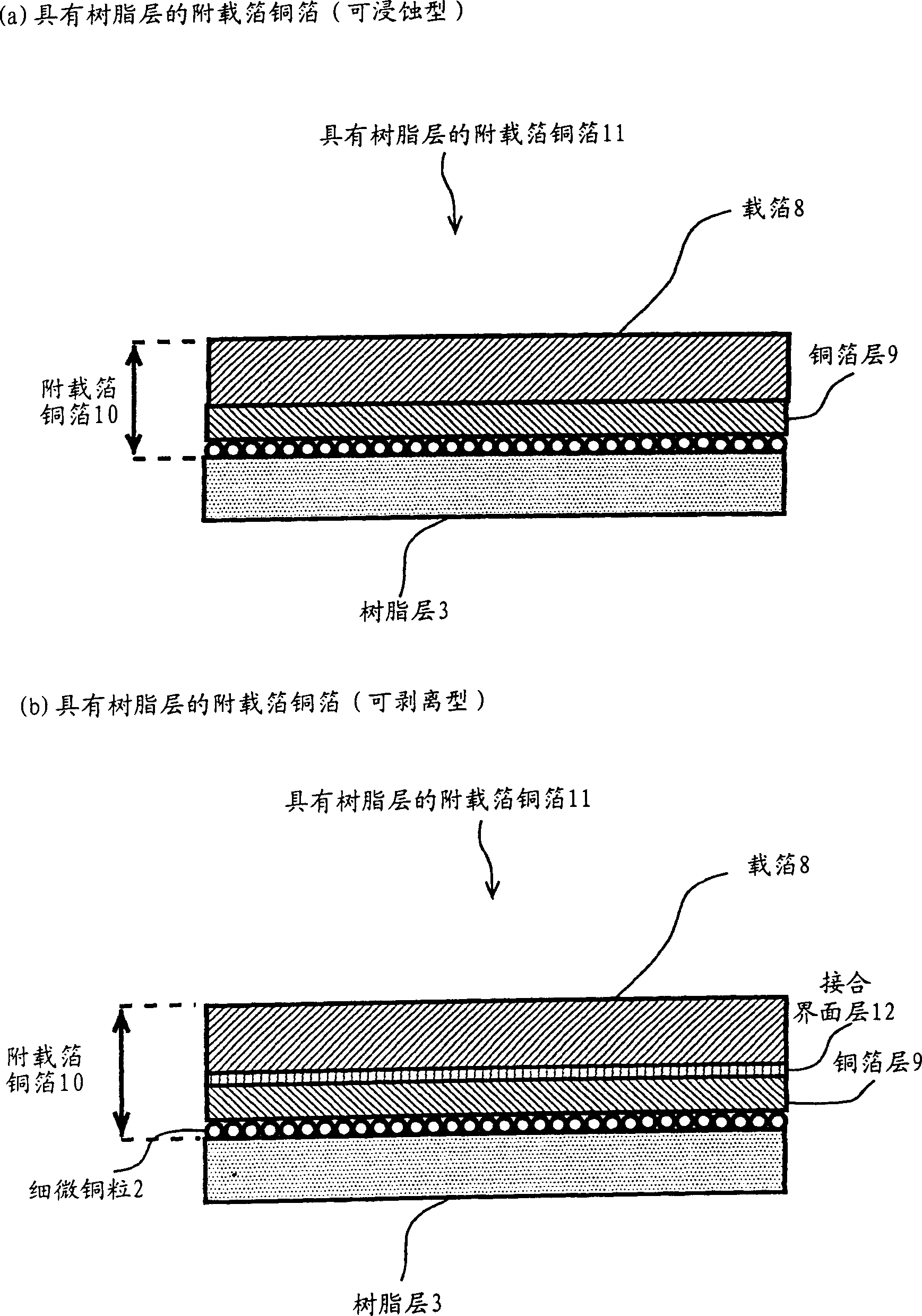

[0046] Here, the copper foil described in claim 2 is used, that is, the copper foil 10 with an etchable carrier foil, which is formed on the side surface of the aluminum carrier foil 8 with a thickness of 25 μm to form a copper foil circuit with a thickness of 3 μ. Foil layer 9. For the following parts that are the same as in the first embodiment, in order to avoid repetition, this description is omitted. In addition, the same parts are represented by the same symbols as in the first embodiment as much as possible.

[0047] A resin layer 3 with a thickness of 100 microns is formed on the surface of the rough-processed copper foil layer 9 with fine copper particles 2 attached to the copper foil with a carrier 10 to form a carrier foil with the resin layer Copper foil 11. At this time, the resin used for forming the resin layer 3 is the same as in the case of the first embodiment, so the description is omitted.

[0048] Then, use this copper foil 11 with a resin layer attached to Fi...

Embodiment 3

[0050] Here, the copper foil of claim 3, that is, the copper foil 10 with a peelable carrier foil, is formed on the side surface of the 18 micron thick copper carrier foil 8 to form a copper foil corresponding to a thickness of 5 μ to form a copper foil circuit. Layer 9, and the bonding interface layer 12 is formed between the carrier foil layer 8 and the copper foil layer 9 with carboxy benzotriazole. For the following parts that are the same as in the first embodiment, in order to avoid repetition, this description is omitted. In addition, the same parts are represented by the same symbols as in the first embodiment as much as possible.

[0051] A resin layer 3 with a thickness of 100 microns is formed on the surface of the rough-processed copper foil layer 9 with fine copper particles 2 attached to the copper foil with a carrier 10, thereby forming a carrier foil with the resin layer Copper foil 11. At this time, the resin used to form the resin layer 3 is the same as in the case...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com