Process for removing PH3 from residual gas after fumigant insect killing

A technology of residual gas and gas distributor, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to achieve the effect of simple process and equipment, convenient operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

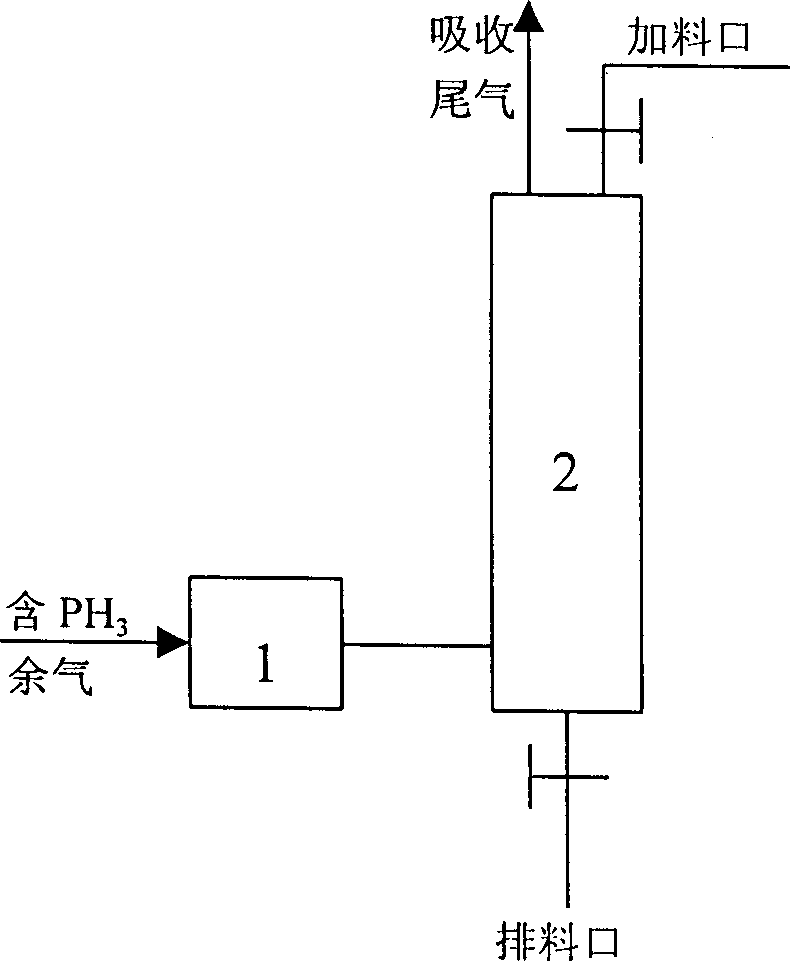

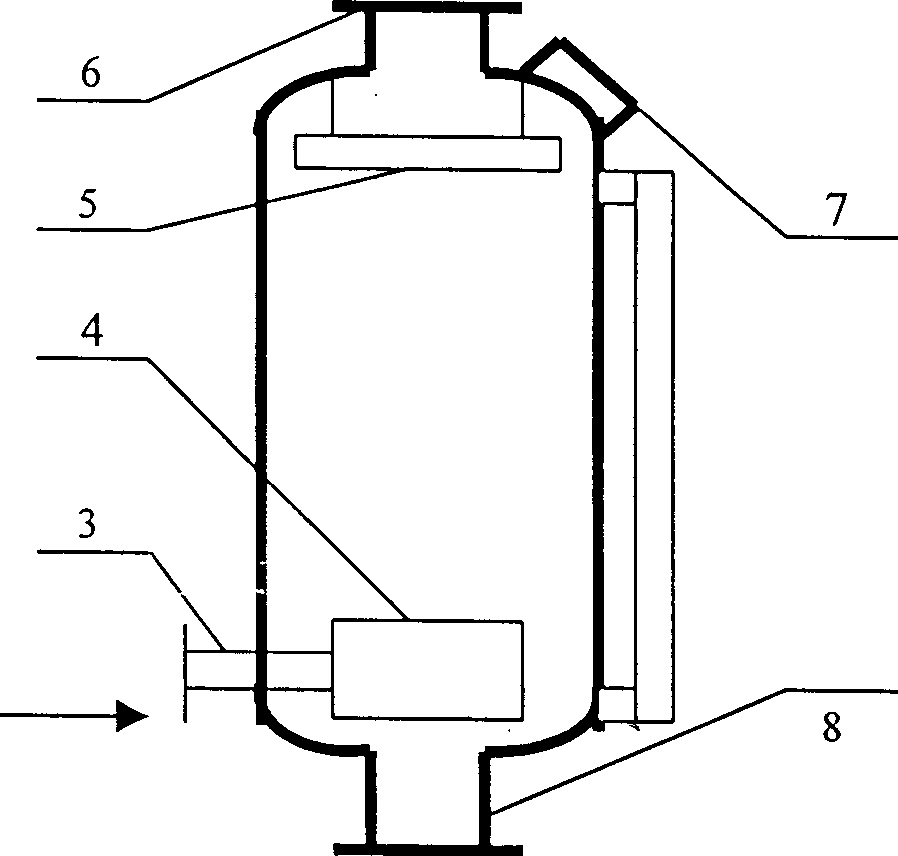

Method used

Image

Examples

Embodiment 1

[0022] Take 1000ml of saturated bleaching powder solution (solvent is deionized water), and add it into the absorption tower with a diameter of ф70mm and a height of h=500mm. The operating conditions are as follows: normal temperature and normal pressure; the air velocity of the absorption tower is 70mm / s; the inlet pH 3 The concentration is 180ppm. Result: Export PH 3 It can't be detected by the specific length tube test method and chemical analysis method, that is, it is close to zero.

Embodiment 2

[0024] Take 600ml of saturated bleaching powder solution (solvent is deionized water) and 400ml of deionized water, and add them together into an absorption tower with a diameter of ф70mm and a height of h=500mm. The operating conditions are as follows: normal temperature and normal pressure; the air velocity of the absorption tower is 93mm / s; the inlet pH 3 The concentration is 240ppm. Result: Export PH 3 It can't be detected by the specific length tube test method and chemical analysis method, that is, it is close to zero.

Embodiment 3

[0026] Take 80g of bleaching powder, dissolve it in 1000ml of tap water, and add it into an absorption tower with a diameter of ф70mm and a height of h=500mm. The operating conditions are as follows: normal temperature and normal pressure; the air velocity of the absorption tower is 36mm / s; the inlet pH 3 The concentration is 360ppm. Result: Export PH 3 It can't be detected by the specific length tube test method and chemical analysis method, that is, it is close to zero.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com