Use of CsOH in dielectric CMP slurry

A dielectric layer and integrated circuit technology, applied in the direction of circuits, electrical components, polishing compositions containing abrasives, etc., can solve the problems of high polishing defect rate, poor planarization effect, and low polishing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

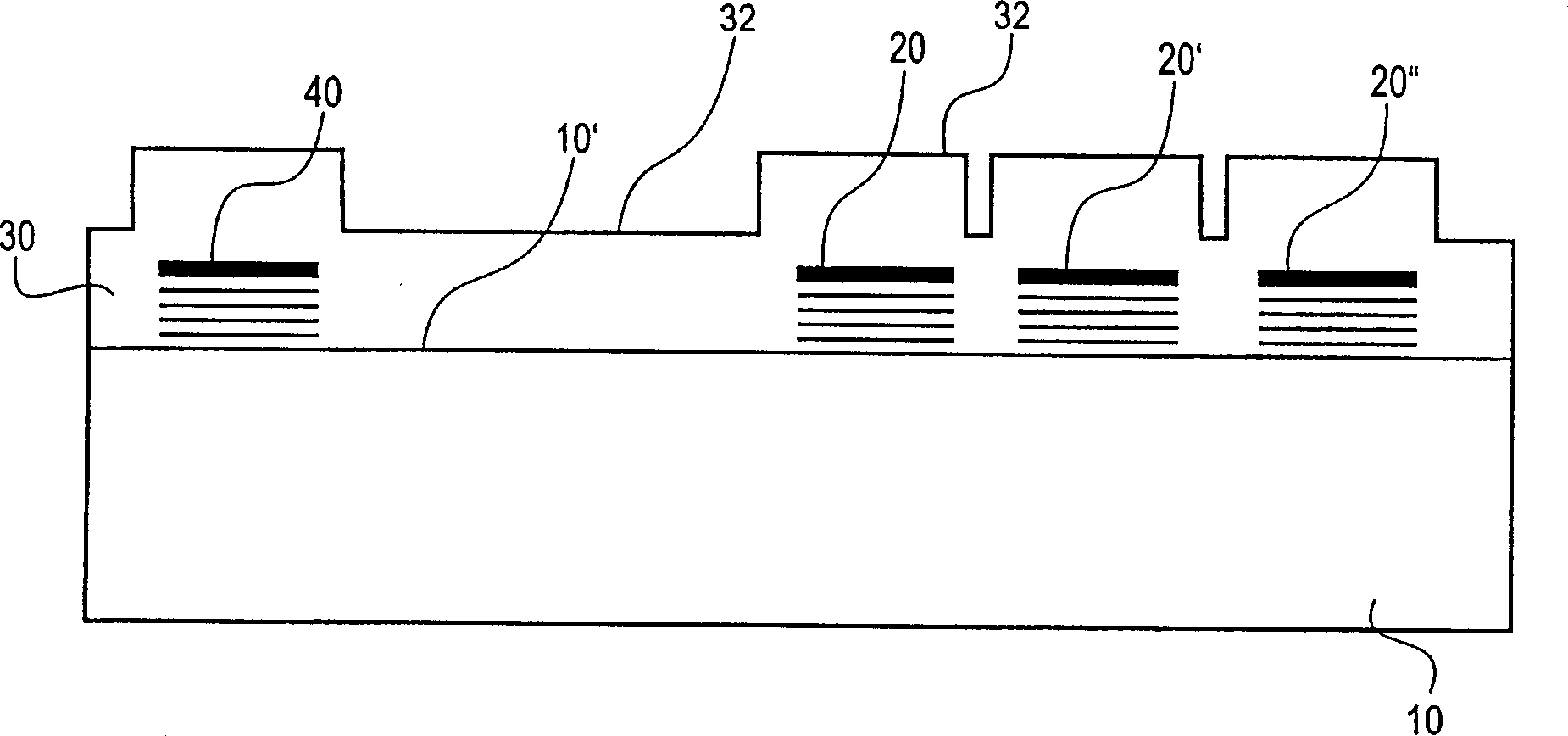

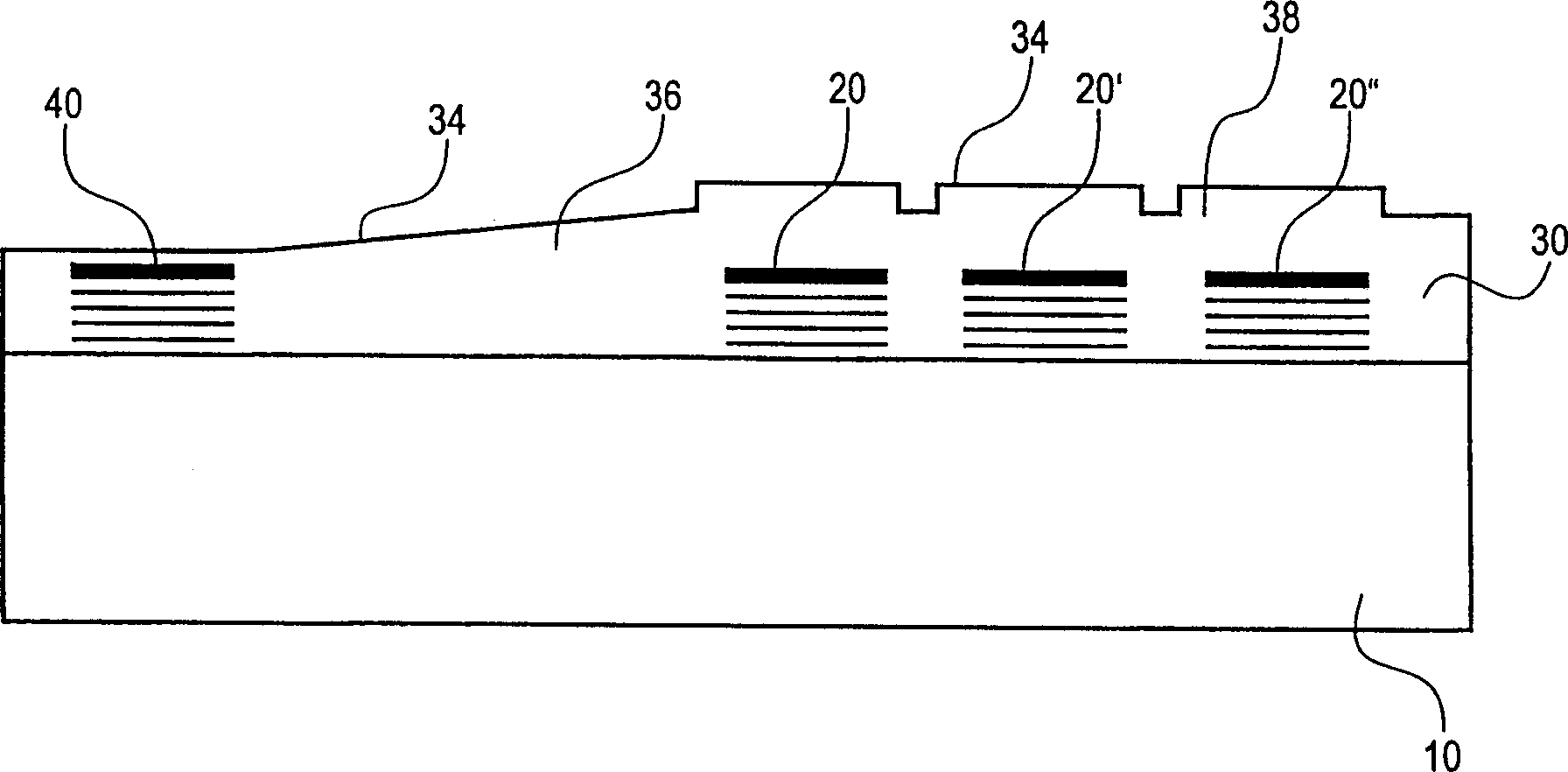

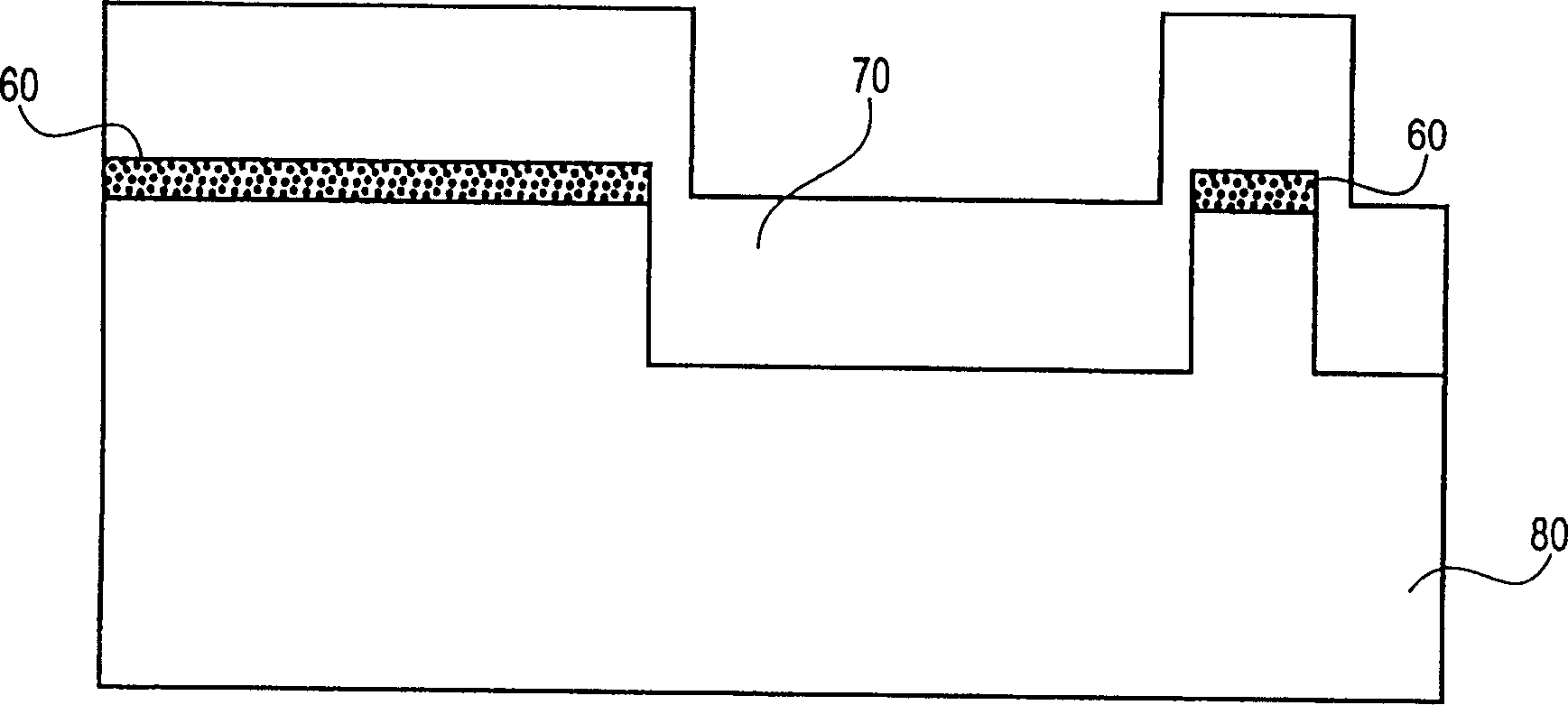

Method used

Image

Examples

Embodiment 1

[0044] This example evaluates the ability of compositions containing various oxyhydroxides to polish silicon-containing substrates with high efficiency and low defectivity.

[0045] The polishing slurry compositions are shown in Table 1 below. Each polishing composition contains CAB-O-SPERSE manufactured by Cabot Corporation SC-E calcined silica. The slurries were stabilized with CsOH or KOH, ie each base was added to each slurry in sufficient amount to increase the slurry pH to 10.8. The polishing composition was used to planarize a test wafer. The test wafer is a test pattern of a mask designed for MIT, in which aluminum lines are grown on a silicon substrate. The wafer has a step height of approximately 9000 Angstroms. The pattern has a line pitch of 250 microns with a regularly varying density ranging from 100 to 8%, where 100% means 100% of the overlay area and 25% means the lines are thick enough that 25% is overlay area and 75% is field area.

[0046] Field meas...

Embodiment 2

[0058] In the present embodiment, it is to evaluate including CsOH, KOH and NH 4 Planarization rate of OH polishing slurries. Each of the tested slurries contained 12 weight percent CAB-O-SPERSE SC-E calcined silica (manufactured by Cabot Corporation). The slurry is made of CsOH, KOH or NH 4OH stabilization, ie sufficient amount of each base was added to each slurry to increase the slurry pH to 10.8. Each of the slurries was used to polish the wafers described in Example 1 according to the method described in Example 1.

[0059] Flatten the result with Figure 5 and Figure 6 Illustrated. according to Figure 5 , the planarization rates of CsOH and KOH slurries are better than those containing NH 4 OH slurry. according to Figure 6 , the slurry containing CsOH is more than that containing KOH or NH 4 OH slurries also planarize silicon substrates more efficiently. with KOH and NH 4 Compared with the OH slurry, the CsOH slurry can be seen to have greater efficienc...

Embodiment 3

[0061] This example evaluates the planarization rate of commercially available polishing slurries. The first slurry, D7000, is a 10.5 weight percent dispersion of fumed silicon stabilized with KOH. The second slurry was Klebsol 30N50, a colloidal silica (manufactured by Clariant) stabilized with 30 weight percent ammonia. Each of the slurries was used to polish the wafers described in Example 1 according to the polishing method described in Example 1.

[0062] The planarization results are shown in Table 2.

[0063] Serum Composition

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com