Structure mode of electro-mobile power and driving device

A technology for electric vehicles and transmissions, which is applied to electric power units, power units, vehicle components, etc., can solve the problems affecting the comfort and stability of the vehicle, increase the driving power of the vehicle, and the space occupied by the transmission. The effect of reduced weight, lower energy consumption and reduced maintenance effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

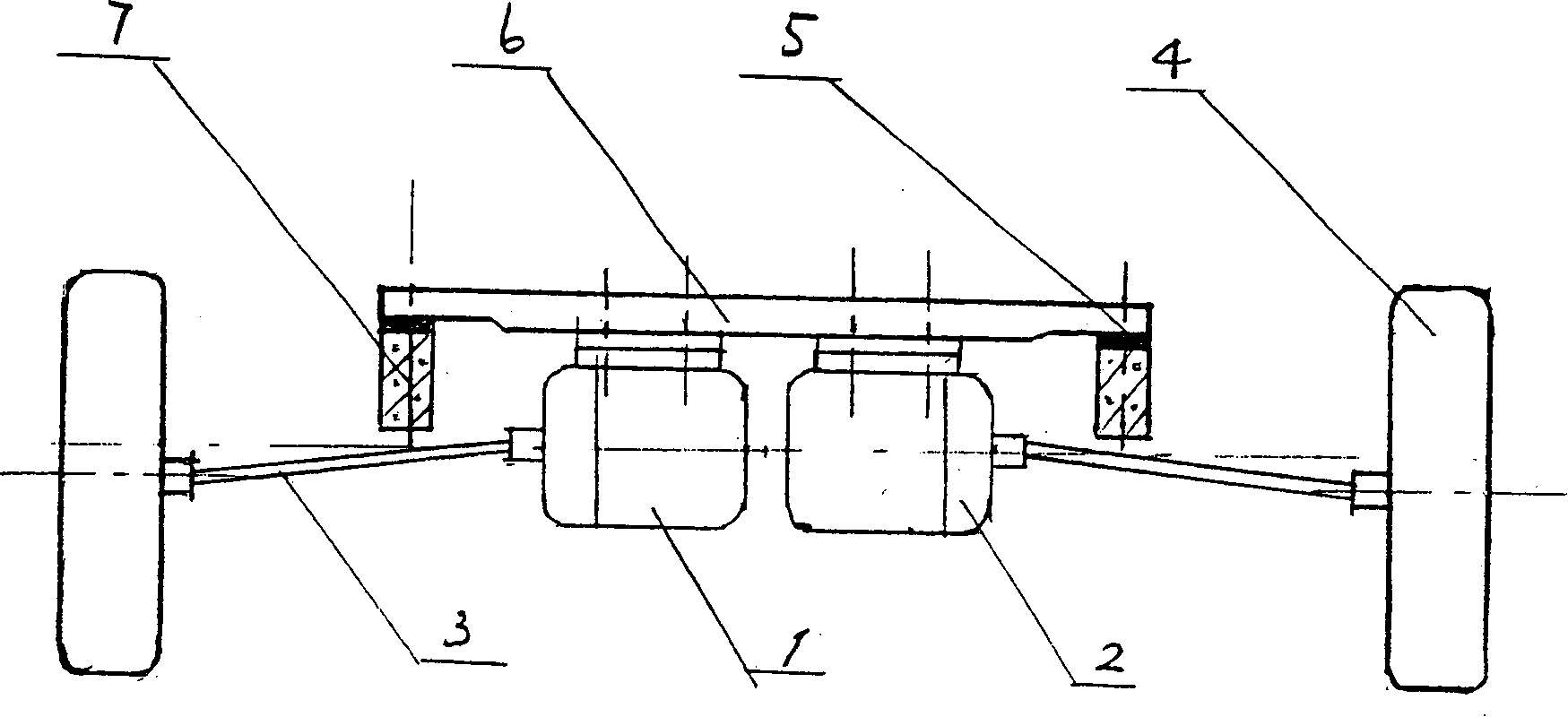

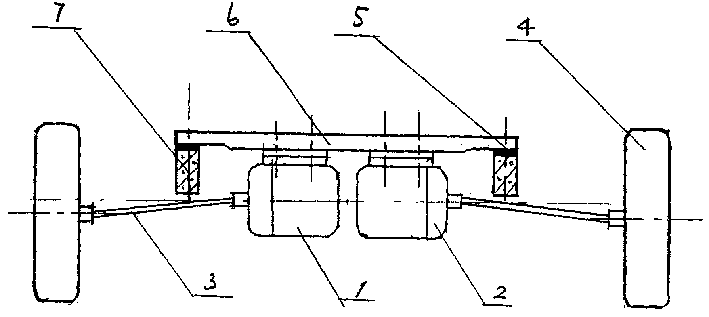

[0013] Example: Combine figure 1 Examples of the present invention will be described. The present embodiment is the power of a newly developed certain electric car and its transmission device. The body of the car is made of composite materials, with a curb weight of 1027kg. In the front power compartment, there are two longitudinal beams (7) connected to the left and right inner fenders, and the rear part is connected to the dash panel, which is the main load-bearing structure of the vehicle body. (5) Link to each other with the longitudinal beam of the vehicle body, two motors (1) are installed below the mounting bracket, because this motor is a high-speed motor n=8000r / m, the output end of the motor is equipped with an 8:1 planetary reducer (2), The output shaft of the speed reducer is provided with a ball cage of a constant velocity joint, and is connected with another ball cage inside the traveling wheel (4) through a transmission shaft. Since the motor is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com