Equipment for preparing regenerated fluoride salt or alumina from waste of aluminium electrolysis

A technology for waste and fluoride salt, which is applied in the field of devices for producing regenerated fluoride salt and alumina from aluminum electrolysis waste, can solve the problems of inability to automatically discharge materials, unfavorable industrial production, and short service life of air distribution panels. , to achieve the effect of simple operation, elimination of fusible furnace agglomeration, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

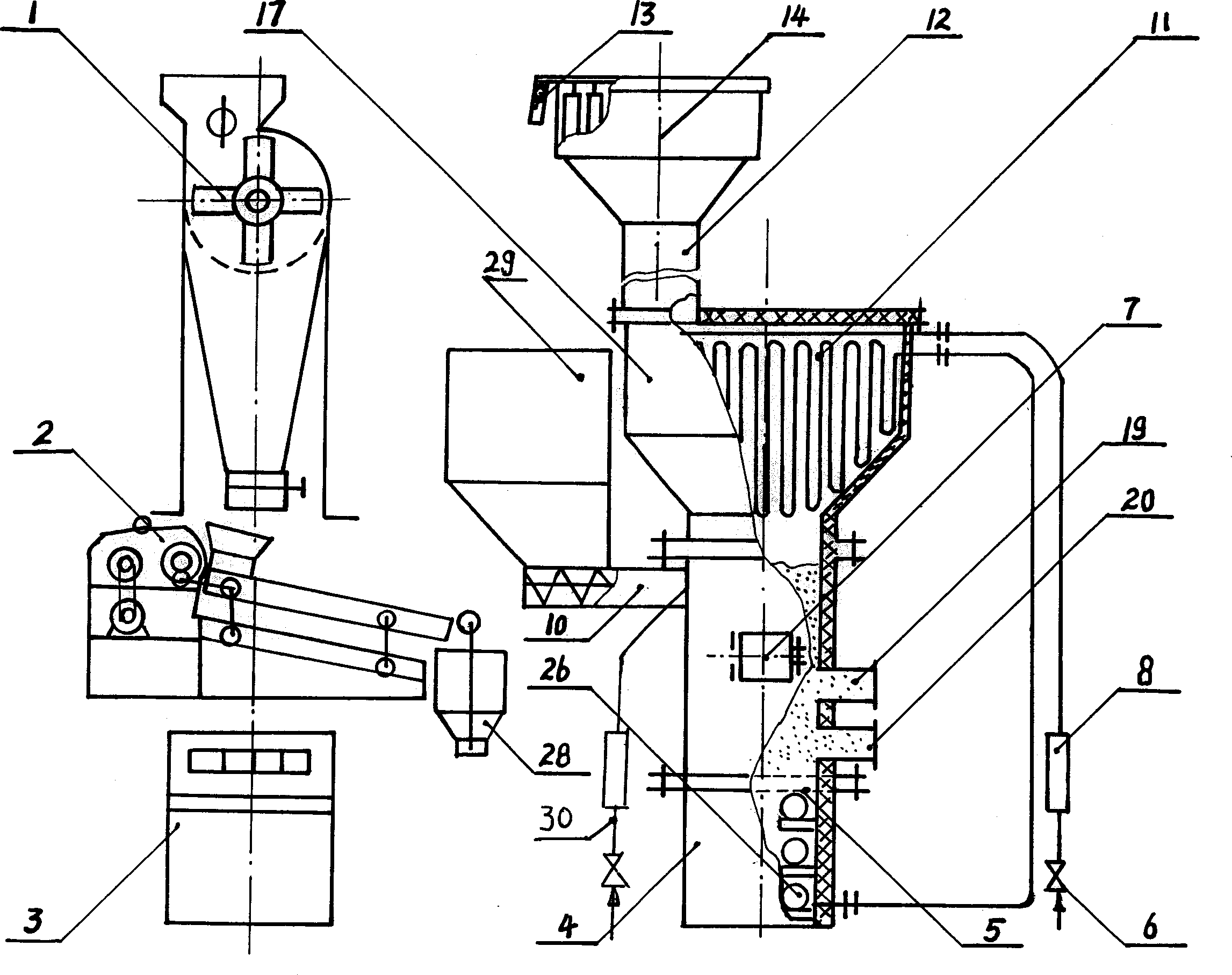

[0014] figure 1 , image 3 As shown, the present invention is formed on the basis of the main furnace with waste heat complementary structure in the ZL96115111.0 patent by adding a pneumatic bulking device 30. The pneumatic bulk feeder 30 is installed at the discharge port of the feeder 10 of the main furnace 17 .

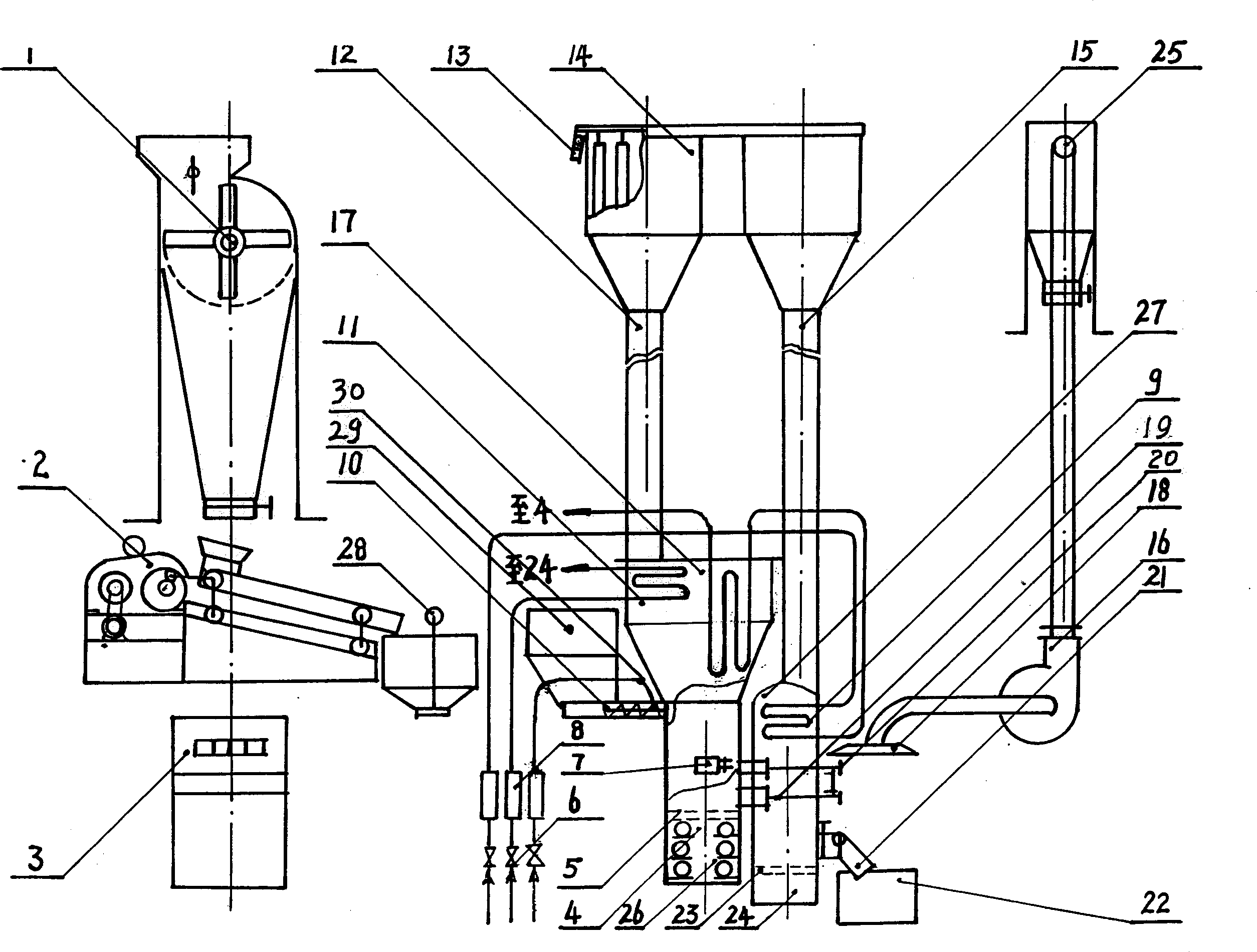

[0015] figure 2 As shown, the present invention is based on the ZL96115111.0 patent with the main and auxiliary furnace waste heat complementary structure to add a pneumatic bulking device 30. The pneumatic bulk feeder 30 is installed at the discharge port of the feeder 10 of the main furnace 17 .

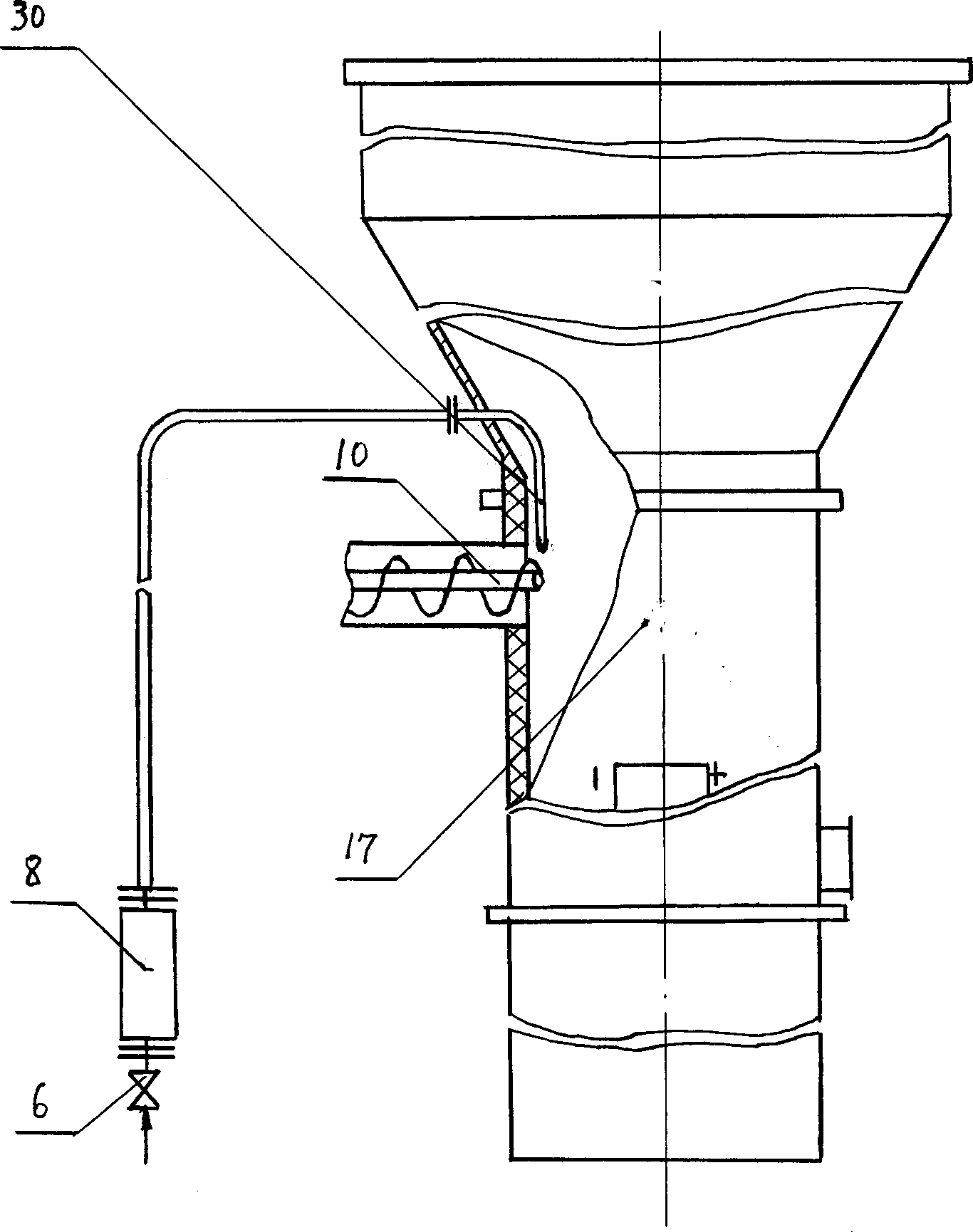

[0016] The pneumatic bulk feeder 30 of the present invention is composed of a compressed air pipeline with a flow meter; the air outlet of the compressed air pipeline is arranged at the material outlet of the feeder 10, and Nozzles are provided at the tuyere. Increase the height of the main furnace 17 of the device of the present invention to 5.5 meters, and its d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com