Method for reducing aromatic content of diesel oil in residual hydrogenation equipment

A technology for residual oil hydrogenation and diesel oil, applied in the direction of aromatic hydrocarbon hydrogenation refining, etc., can solve the problems of increased investment, increased hydrogen consumption, high-pressure device investment and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

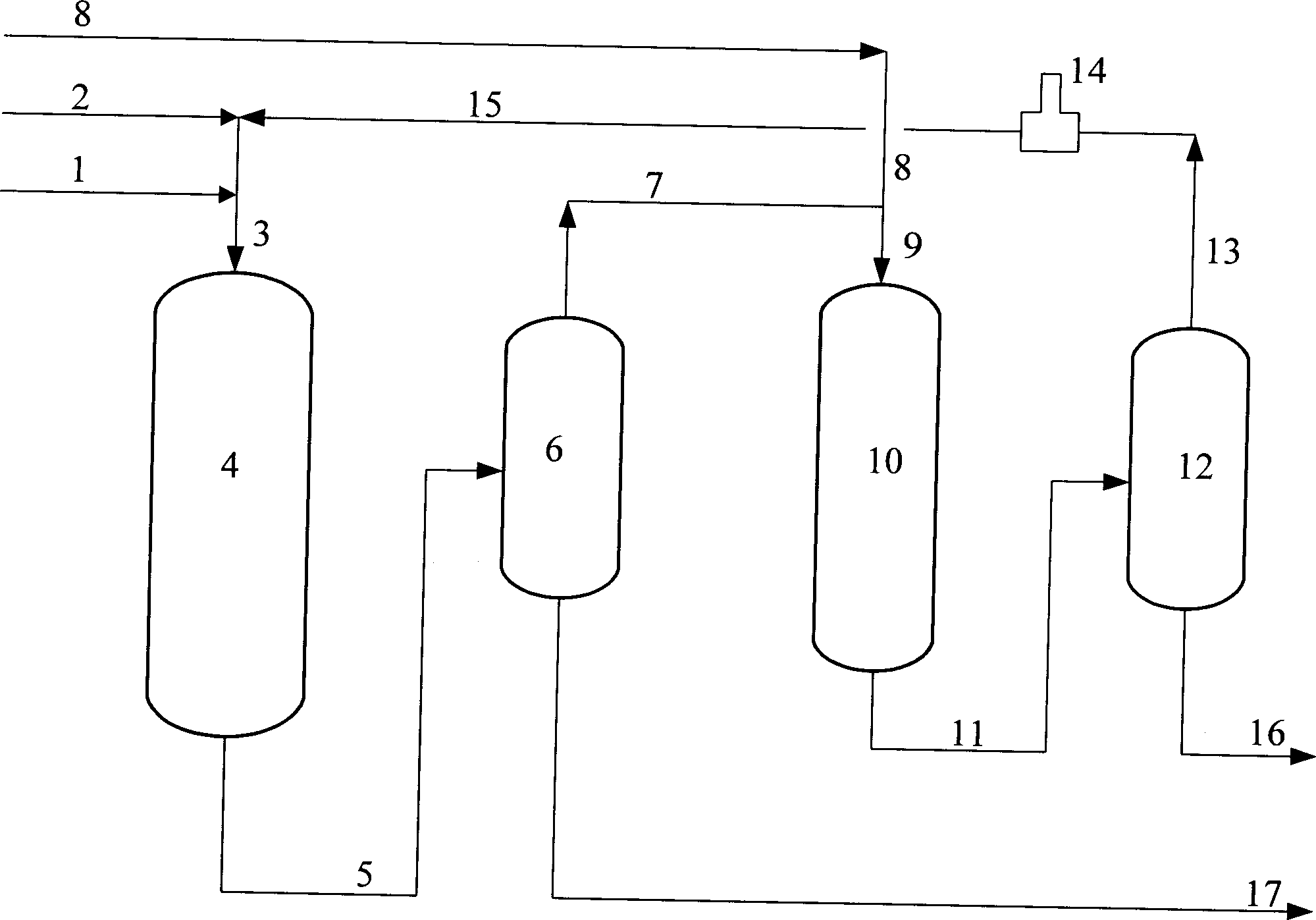

Image

Examples

Embodiment 1

[0031] The diesel feedstock is a heavy oil catalytic cracking diesel, and its properties are shown in Table 1. The catalyst used in the test was produced by the Catalyst Factory of Changling Refining and Chemical Co., Ltd., Sinopec Corporation, and the trade name was RN-10. The gas from the hot high-pressure separator of the residual oil hydrogenation test device is used as the circulating gas of the diesel hydrofining test device. The total pressure of the circulating gas is 15.3MPa, and the hydrogen partial pressure is 14.0MPa. 2 The S content is 32000ppm. The cycle gas contains a certain amount of diesel and naphtha components. Other conditions for diesel hydrotreating are: temperature 350°C, diesel air velocity 1.0h -1. See Table 2 for the yield of various fractions of diesel oil refined and the properties of diesel oil. It can be seen from Table 2 that the diesel yield exceeds 100%, and a certain amount of naphtha is produced, and the diesel part and naphtha exceeding...

Embodiment 2

[0033] Compared with Example 1, the diesel hydrotreating reaction temperature is 380°C, and other operating conditions of diesel feedstock and catalyst are exactly the same as those of Example 1. The properties of hydrogenated oil are shown in Table 2. It can be seen from Table 2 that the aromatics content of the diesel is less than 15% by weight, the cetane number is 46.8, and the sulfur and nitrogen contents are respectively less than 10ppm and 1ppm. The properties of the diesel oil have been greatly improved and become a very good diesel blending component.

Embodiment 3

[0035] The diesel feedstock is a heavy oil catalytic cracking diesel, and its properties are shown in Table 1. The catalyst used in the test was produced by the Catalyst Factory of Changling Refining and Chemical Co., Ltd., China Petroleum & Chemical Corporation, and the trade name was RN-10. The gas from the hot high-pressure separator of the residual oil hydrogenation test device is used as the circulating gas of the diesel hydrofining test device. The total pressure of the circulating gas is 15.3MPa, and the hydrogen partial pressure is 14.0MPa. The hydrogen sulfide content in the ring gas is 32000ppm. In order to directly investigate the effect of this method on the improvement of FCC diesel oil and eliminate the influence of diesel oil and naphtha entrained in the recycle gas, in this embodiment and the following examples, the recycle gas is first cooled and separated Diesel and naphtha fractions, gas and FCC diesel are mixed and heated to reaction temperature for reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com