Resin based composite material manhole cover

A composite material and resin-based technology, applied in infrastructure engineering, artificial islands, underwater structures, etc., can solve the problems of complicated processing, manufacturing and installation, inconvenient use, complicated production process, etc., and achieve long molding cycle, Effect of cost reduction and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

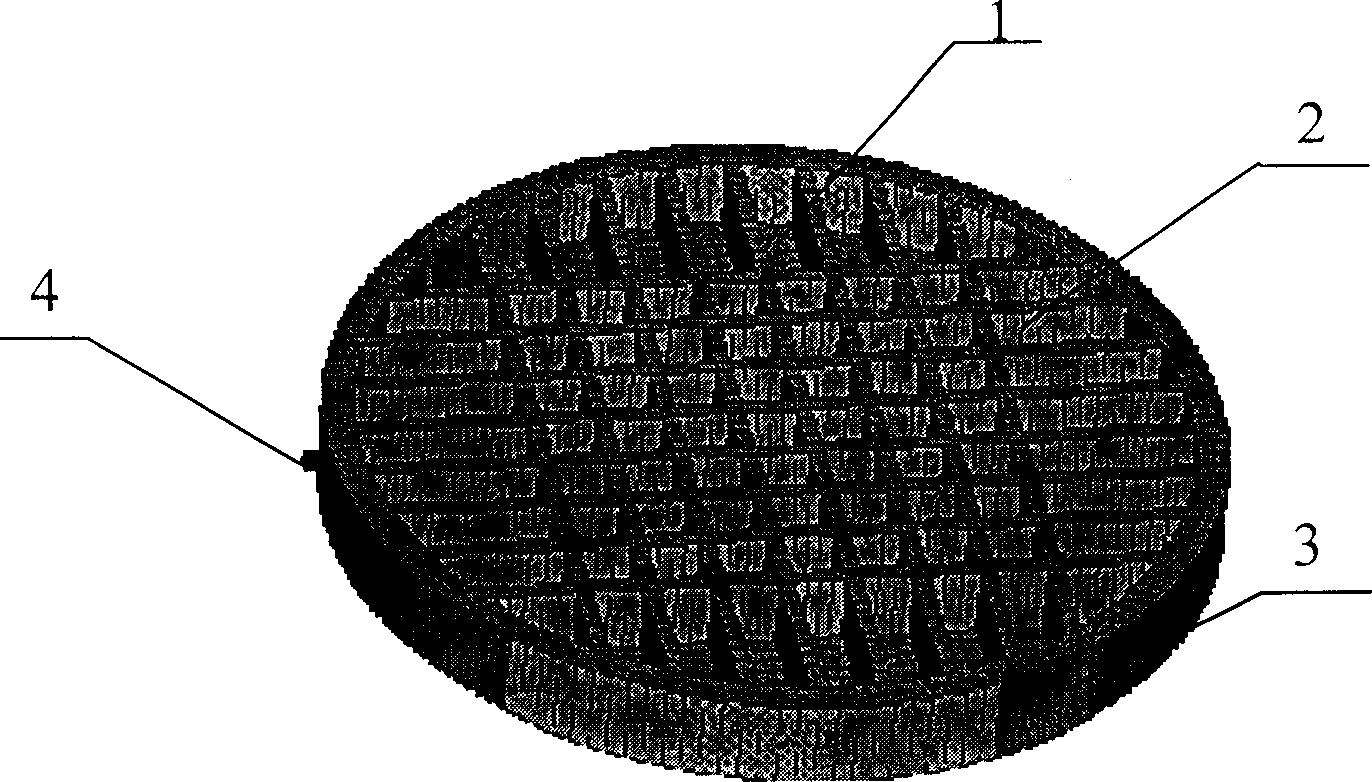

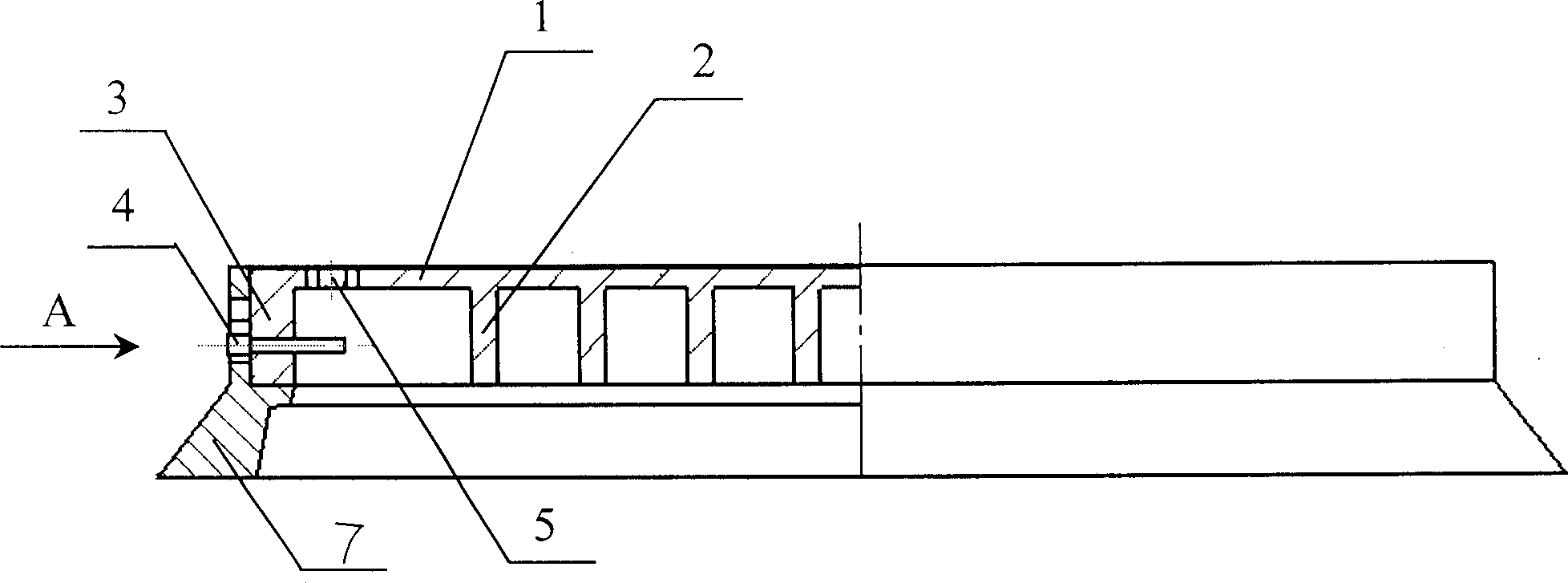

[0023] like figure 1 , 2 As shown, a resin-based composite manhole cover includes: a support edge 3 matched with a support 7, a plate 1 for closing the wellhead, a reinforcing rib 2 arranged under the plate, and a cover hole 5 located on the plate. Rib 2 is a grid rib composed of 8 criss-cross ribs. The composite material is composed of unsaturated polyester resin, alkali-free glass fiber, methyl ethyl ketone peroxide, cobalt styrene isozincate solution, and its weight percentage is: 57% of unsaturated polyester resin, 35% of alkali-free glass fiber, over Methyl ethyl ketone oxide 1%, cobalt styrene isozincate solution 2%.

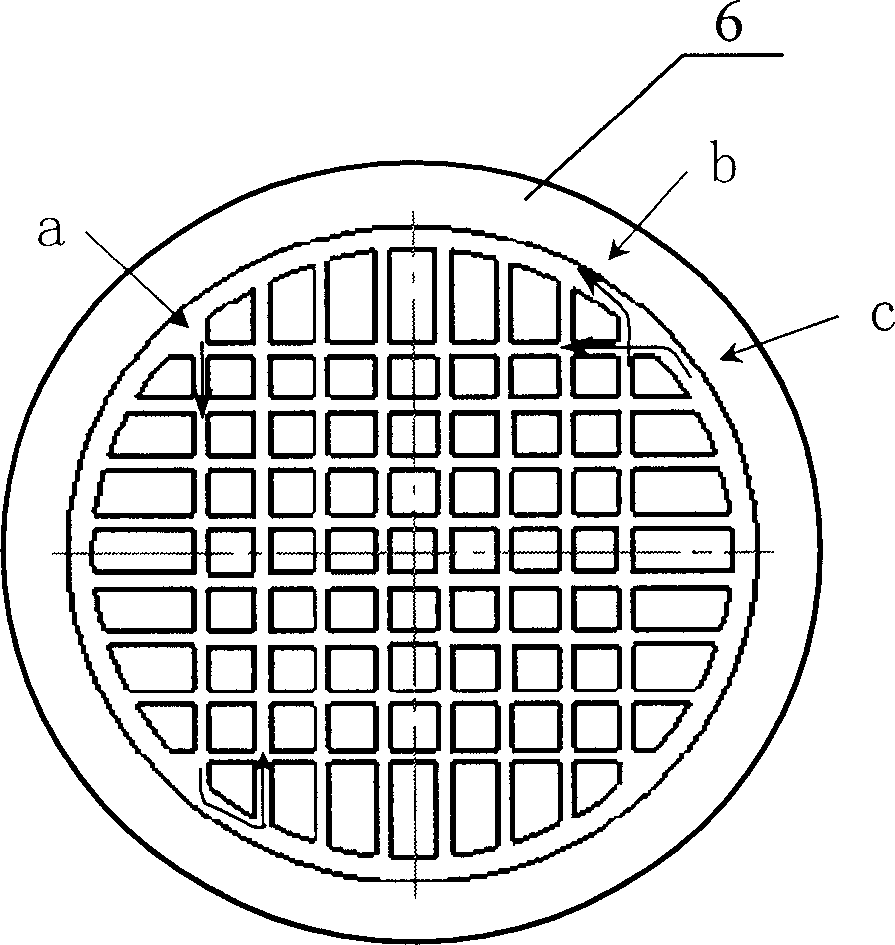

[0024] like image 3 , 4 , Shown in 5, the production method of resin-based composite material manhole cover, its process step is:

[0025] (1) 35% of the glass fiber is wound around the glass fiber bundle at the stiffener position of the mold cavity 6, and 18 layers of glass fiber grid cloth interlaced at 45 degrees and 0.4 mm are laid on the plate p...

Embodiment 2

[0030] like figure 1 , 2 As shown, a resin-based composite manhole cover includes: a support edge 3 matched with a support 7, a plate 1 for closing the wellhead, a reinforcing rib 2 arranged under the plate, and a cover hole 5 located on the plate. Rib 2 is a grid rib composed of 8 criss-cross ribs. The composite material is composed of unsaturated polyester resin, alkali-free glass fiber, methyl ethyl ketone peroxide, cobalt styrene isozincate solution, and its weight percentage is: 50% of unsaturated polyester resin, 45% of alkali-free glass fiber, over 2% methyl ethyl ketone oxide, 3% cobalt styrene isozincate solution.

[0031] like image 3 , 4 , Shown in 5, the production method of resin-based composite material manhole cover, its process step is:

[0032] (1) Wrap 45% of the glass fibers around the ribs of the 6 cavity of the mold to wind the glass fiber bundles, and lay 18 layers of glass fiber grid cloth interlaced at 45 degrees and 0.4mm in the plate position of...

Embodiment 3

[0037] like figure 1 , 2 As shown, a resin-based composite manhole cover includes: a support edge 3 matched with a support 7, a plate 1 for closing the wellhead, a reinforcing rib 2 arranged under the plate, and a cover hole 5 located on the plate. Rib 2 is a grid rib composed of 8 criss-cross ribs. The composite material is composed of unsaturated polyester resin, alkali-free glass fiber, methyl ethyl ketone peroxide, cobalt styrene isozincate solution, anti-aging agent, flame retardant, color paste, and its weight percentage is: unsaturated polyester resin 50%, 45% non-alkali glass fiber, 2% ethyl ketone peroxide, 3% cobalt styrene isozincate solution, 2.5% anti-aging agent, 4% flame retardant, 4% color paste.

[0038] like image 3 , 4 , Shown in 5, the production method of resin-based composite material manhole cover, its process step is:

[0039] (1) Wrap 45% of the glass fibers around the ribs of the 6 cavity of the mold to wind the glass fiber bundles, and lay 9 la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com