Catalyst used in furfural gaseous phase hydrogenation to prepare furyl alcohol and its preparation method

A technology for preparing furfuryl alcohol and catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of high price and dependence on imports of catalysts, and achieve the preparation method Simple, easy to industrialized production, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

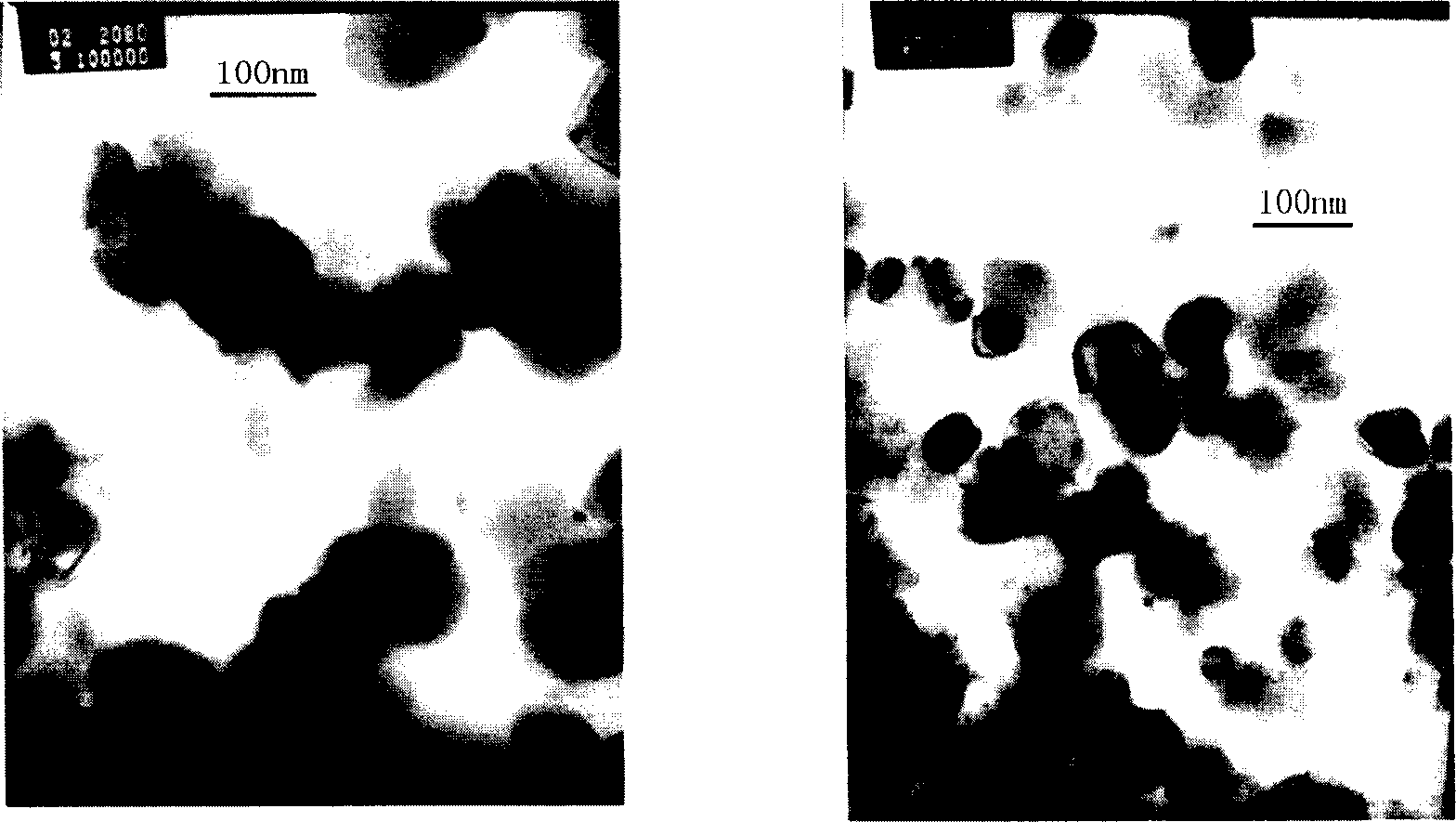

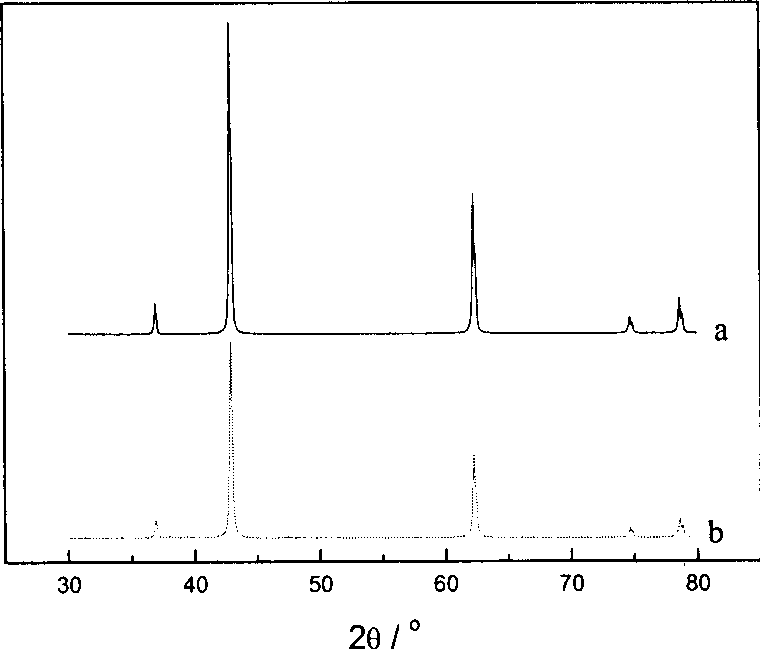

[0020] After the commercially available heavy conventional MgO is subjected to mechanical pulverization and ultrafine treatment by jet mill, its relatively regular grain shape becomes irregular, and various defects appear on the crystal surface, and this surface lattice defect will make the carrier The nature has changed greatly. The conventional MgO carrier (with an average particle diameter of 200nm) is mechanically pulverized to obtain an ultrafine MgO carrier with a particle diameter in the range of 40-100nm. In addition, it can be seen that the crystallinity of MgO becomes lower from the weakening of the peak intensity of the XRD spectrum and the broadening of the diffraction peak (see the accompanying drawing).

[0021] The ultrafine MgO support was calcined at 400°C for 4h.

[0022] Mix 67.5ml, 0.5M copper nitrate solution and 10.4ml, 0.5M cobalt nitrate solution evenly. Weigh 5g of ultrafine MgO carrier and slowly add it into the above mixed solution under stirring. ...

Embodiment 2

[0025] The 67.5ml, 0.5M copper nitrate solution in Example 1 was replaced with 67.5ml, 0.75M copper nitrate solution, Cu content (wt%): 39.82%, Co content (wt%): 3.05%. Other conditions are with embodiment 1.

Embodiment 3

[0027] The 67.5ml, 0.75M copper nitrate solution in Example 2 was replaced with 67.5ml, 1.0M copper nitrate solution, Cu content (wt%): 42.02%, Co content (wt%): 2.63%. Other conditions are with embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com