Mini type electroosmosis pump

An electroosmotic pump and miniature technology, applied in the direction of pumps, electrical components, electromechanical devices, etc., can solve the problems of inability to work continuously for a long time, regular replacement of porous stems, and pumps that cannot be used for a long time, achieving low cost and simple reagent requirements , fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

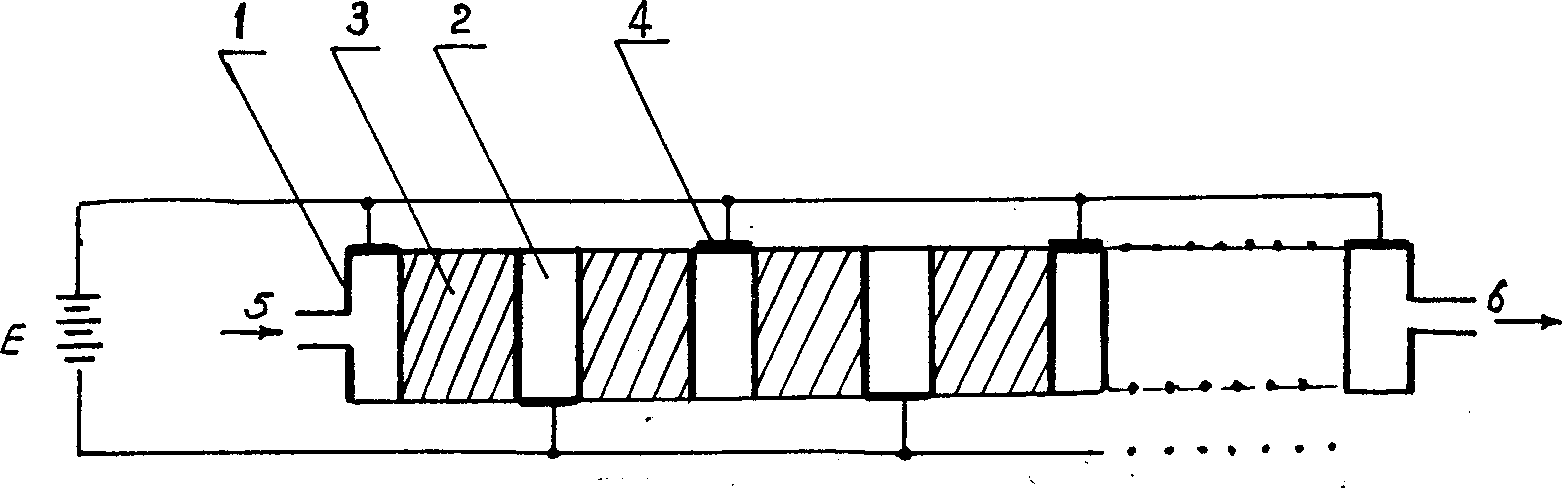

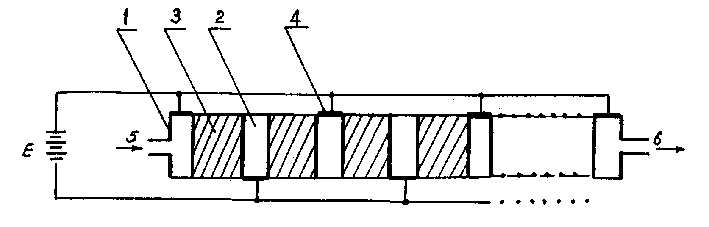

[0012] Such as figure 1 As shown, the present invention is provided with a pump body 1, the pump body can be a unit assembly type or a continuous integrated structure, a fluid channel is arranged in the pump body, and at least three positive and negative electrode chambers 2 are arranged in the fluid channel, and in the electrode chamber Filled with electrolyte solution, a porous core 3 is set between every two electrode chambers, the surface of the porous core is positively or negatively charged, and its thickness is 0.5-10 mm. Each electrode chamber is connected to the power supply E through a conductor 4 . The conductor 4 may be an electronic conductor, or a composite of an ion conductor and an electronic conductor. Anion / cation exchange resin membranes / belts can be used as ion conductors, and reversible electrodes can be used as electronic conductors, such as Ag / AgCl, Ag / Ag 2 O and other electrodes.

[0013] The number of electrode compartments is preferably an odd numbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com