Particle radius, concentration photosensor

An optical sensor and particle size technology, applied in the field of optical sensors, can solve the problems of difficult adjustment, restricted use, multi-phase flow flow field interference, etc., to achieve easy reception and processing, ensure safe use, and small flow field interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

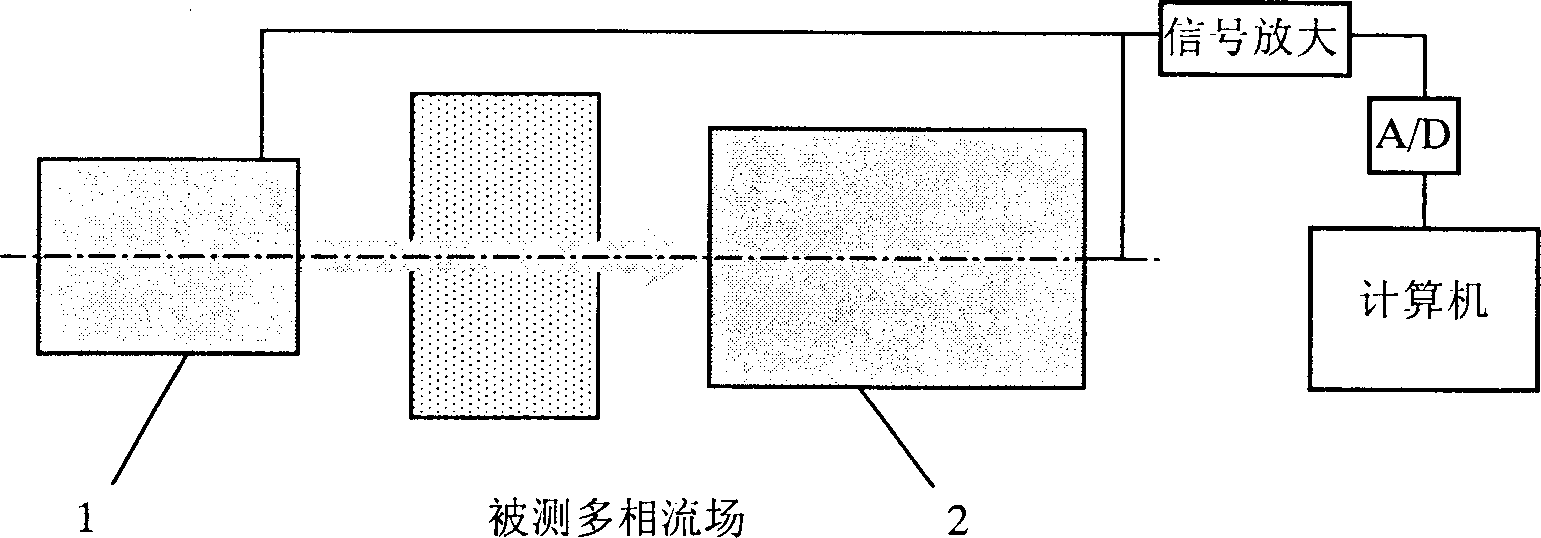

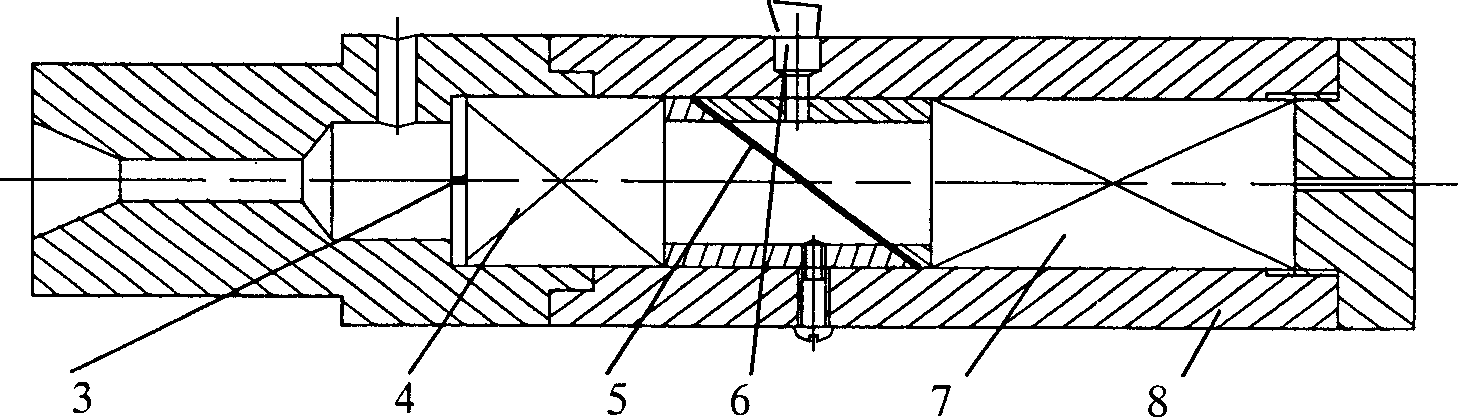

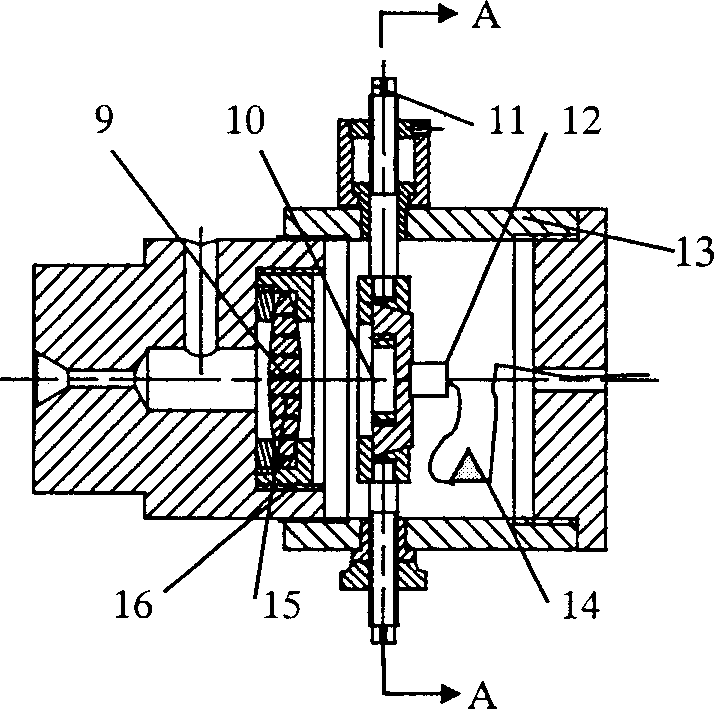

[0019] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, the present invention adopts a separated group pair structure, that is, the present invention is composed of two parts, a transmitting end 1 and a receiving end 2, and the transmitting end 1 includes: a beam limiter 3, a spatial filter 4, a transmission-reflector 5, a reference The light receiving device 6, the semiconductor laser 7 and the cylindrical barrel 8 are connected in the following way: the beam limiter 3, the spatial filter 4, the transmission-reflecting mirror 5, and the semiconductor laser 7 are arranged in sequence and packaged in the cylindrical barrel 8 , the reference light receiving device 6 is fixed on the side wall of the cylindrical barrel 8, and is connected to the external circuit by wires; the receiving end 2 includes: a convex lens and a metal frame 9, an aperture 10, a two-dimensional adjustment device 11, and a photoelectric receiving device 12 , package body 13 and preliminary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com